Machining method of wear-resistant cutters

A processing method and cutting tool technology, which are applied in metal material coating technology, ion implantation plating, coating, etc., can solve problems such as unsatisfactory effect, easy wear of blades, and reduced service life of devices, so as to achieve good impact resistance Performance and wear resistance, improved strength and toughness, and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

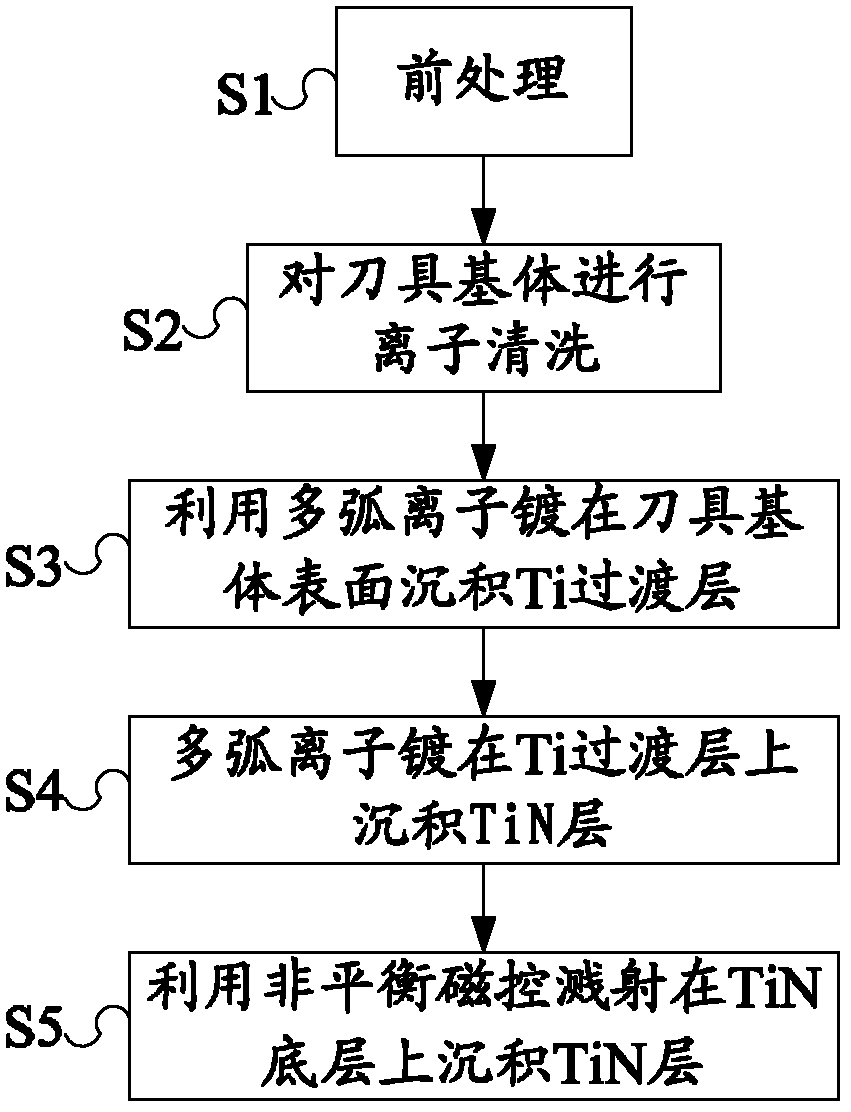

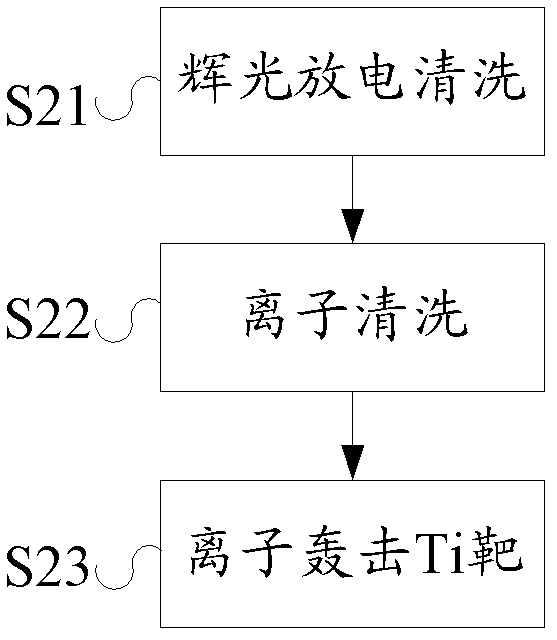

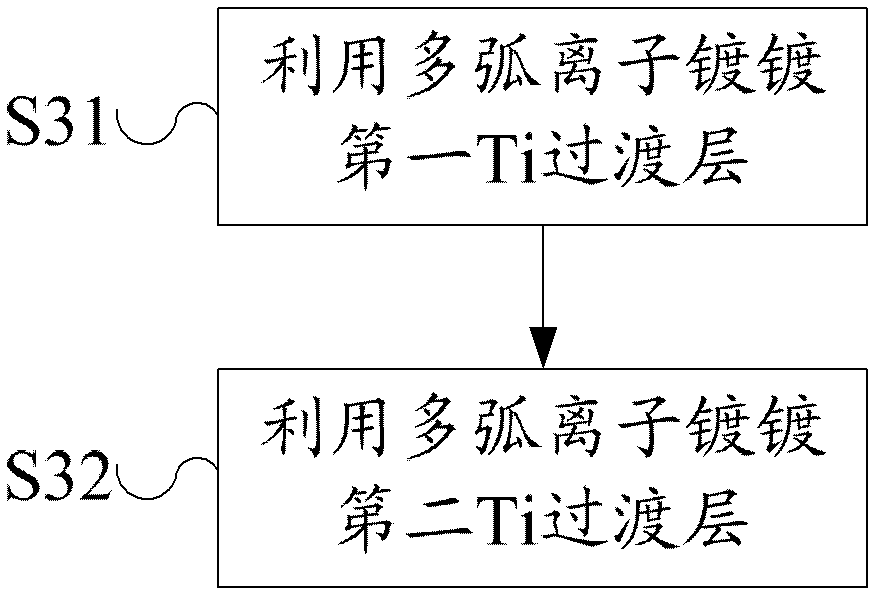

Method used

Image

Examples

Embodiment Construction

[0050] For reference and clarity, the technical terms used below are summarized as follows:

[0051] Multi-arc ion plating: It is an improved vacuum arc ion plating technology, which improves the state of arc discharge through an external magnetic field, refines the arc spot and improves the etching of the cathode target, and improves the flow and orientation of the beam. Reduced droplet density further improves deposition rate, coating quality and adhesion. The method has the advantages of fast deposition speed, high efficiency, uniform coating, and high bonding strength of the coating substrate.

[0052] Magnetron sputtering deposition: It is a pulsed unbalanced magnetron sputtering method, which has the advantages of preparing large-area, multi-component, dense, and high-quality coatings.

[0053] The core of the invention is to provide a processing method for a wear-resistant cutting tool to improve the service life of the cutting tool.

[0054] In order to enable those ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com