High-specific-surface denitration catalyst and preparation and application thereof

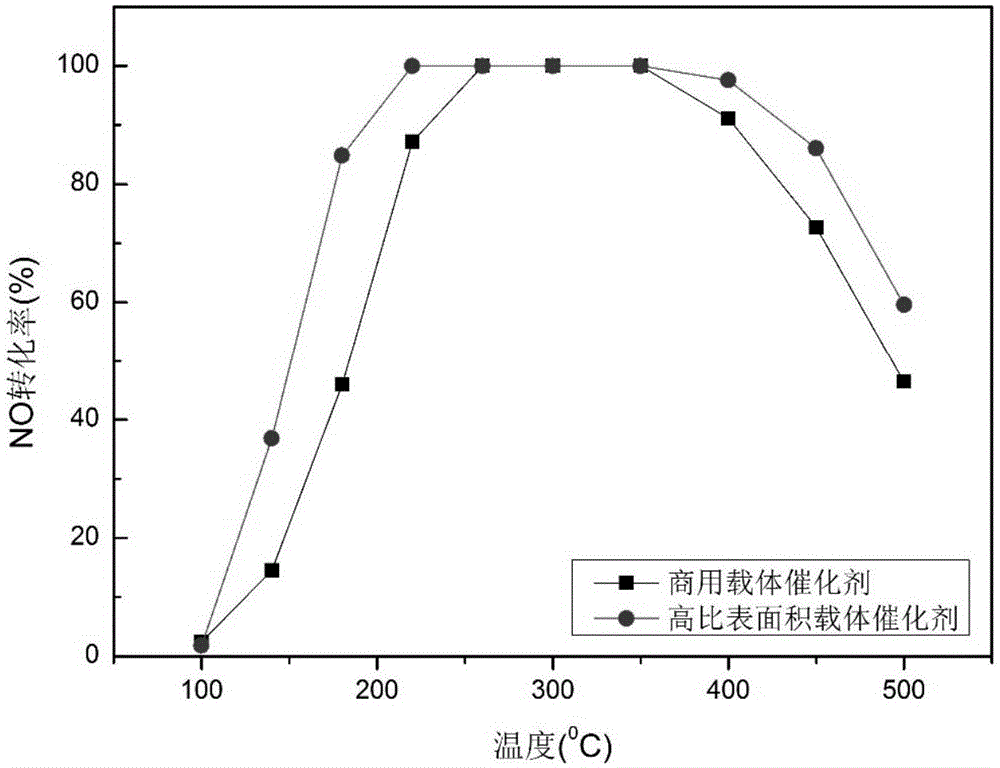

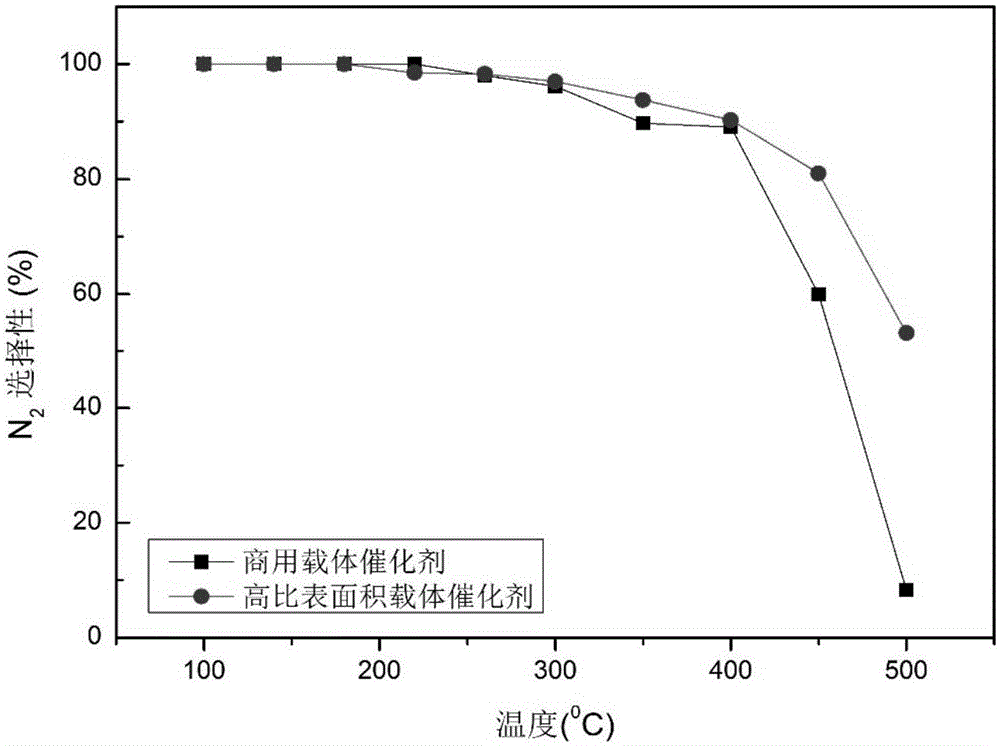

A denitration catalyst, high specific surface technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the limitations of the wide application of denitration catalysts, the catalyst activity temperature window is narrow, and the specific surface area of the carrier is low, etc. problem, to achieve good denitration activity, improve nitrogen oxide conversion rate, and high N2 selectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0032] Embodiment: the preparation of high specific surface area carrier catalyst

[0033] 1. Dissolution of ammonium metavanadate

[0034] Weigh 0.32143g of ammonium metavanadate and 0.40179g of oxalic acid, add them into 100mL of deionized water; carry out magnetic stirring at 80°C for 10min at a speed of 300r / min, until the ammonium metavanadate is completely dissolved to form solution 1;

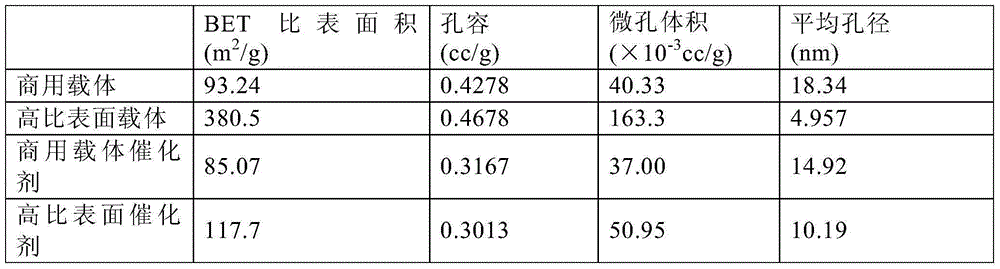

[0035] 2. Preparation of titanium dioxide suspension

[0036] Weigh 4.5g high specific surface area (SBET≥300m 2 / g) Titanium dioxide carrier powder, add 90mL deionized water and mix; carry out magnetic stirring at 80°C for 30min at a speed of 300r / min, until a titanium dioxide suspension is formed, namely solution 2.

[0037] 3. Dipping process

[0038] Pour solution 1 into solution 2, add 200 mL of deionized water to dilute at the same time, and perform magnetic stirring at 80° C. for 1 hour at a speed of 300 r / min. Put the stirred solution into an ultrasonic generator and ultrason...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com