Nanoscale activated calcium carbonate and processing method thereof

A technology of activated calcium carbonate and nano-calcium carbonate, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of affecting the application effect of nanoparticles, poor binding force of base materials, and decline in material properties, etc. The effect of large-scale industrial production, strong bonding force and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

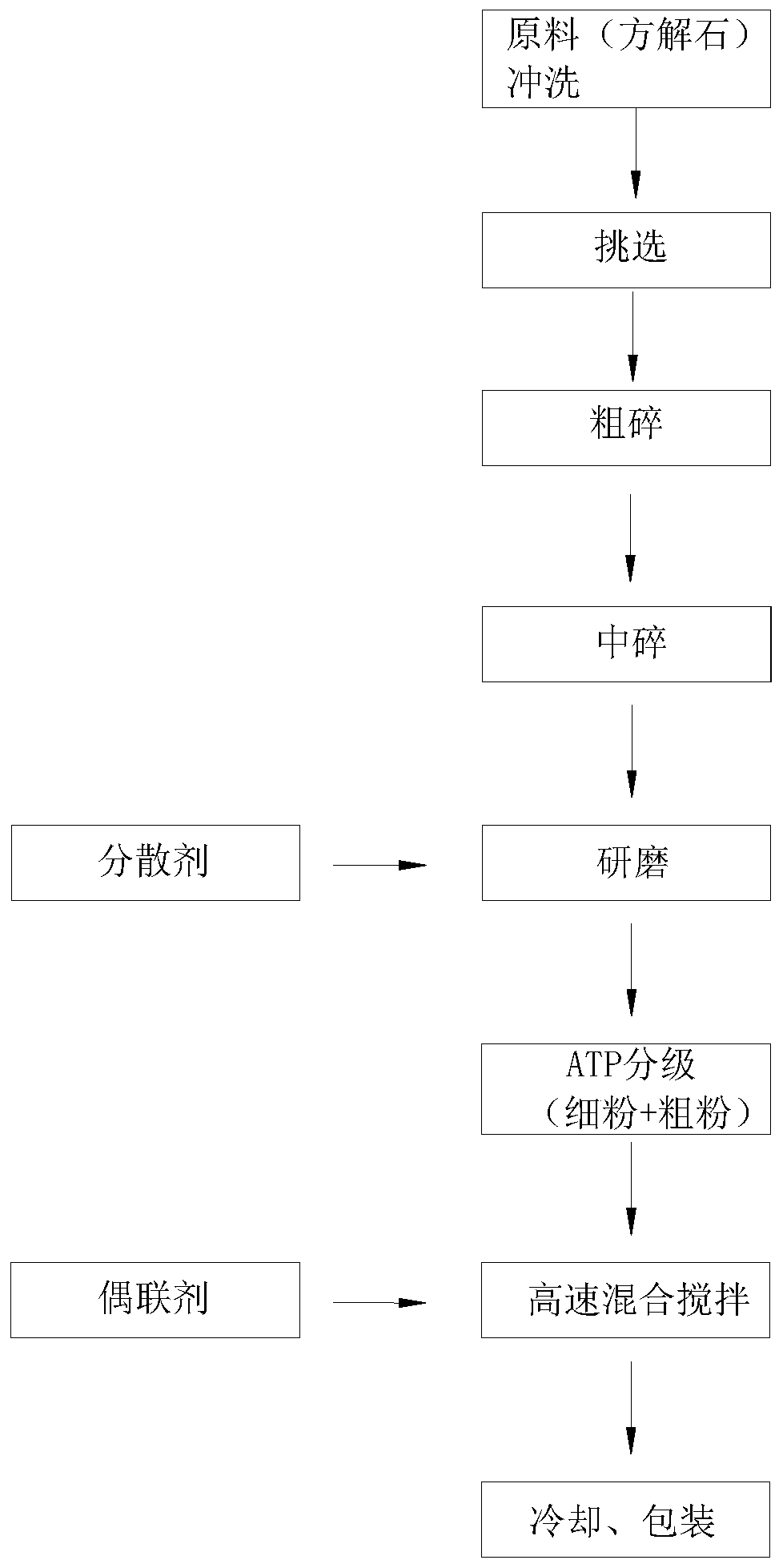

[0036] In the grinding process, the mass fraction ratio of calcium carbonate to dispersant is 100:0.2;

[0037] In the high-speed mixing and stirring process, the mass fraction ratio of dry nano-calcium carbonate to coupling agent is 100:8.

Embodiment 2

[0039] In the grinding process, the mass fraction ratio of calcium carbonate to dispersant is 100:1.5;

[0040] In the high-speed mixing and stirring process, the mass fraction ratio of dry nano-calcium carbonate to coupling agent is 100:6.

Embodiment 3

[0042] In the grinding process, the mass fraction ratio of calcium carbonate to dispersant is 100:3;

[0043] In the high-speed mixing and stirring process, the mass fraction ratio of dry nano-calcium carbonate to coupling agent is 100:3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com