Preparation method of crude terephthalic acid hydrogenation catalyst

A technology of crude terephthalic acid and hydrogenation catalyst is applied in the preparation of organic compounds, the preparation of carboxylate, chemical instruments and methods, etc. The effect of improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

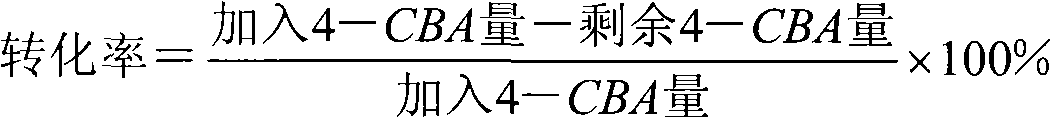

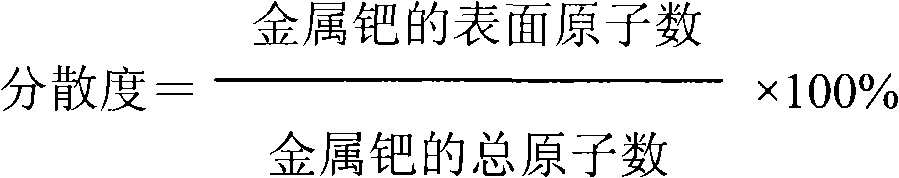

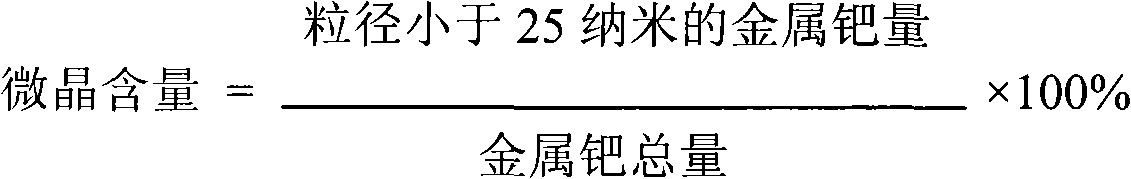

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Weigh 50 grams of 4-8 mesh, flaky coconut shell activated carbon, the specific surface is 1078 square meters per gram, and the pore volume is 0.47 milliliters per gram. After removing the dust adsorbed on the carbon surface and the loose parts on the surface, the activated carbon was pre-impregnated with a tartaric acid solution with a concentration of 0.1 mol / g at room temperature for 15 minutes, then filtered, and dried at 120°C for 2 hours. Take by weighing 1.25 grams of palladium-containing 20% chloropalladium acid solution, add an appropriate amount of surfactant and sodium carbonate to it, adjust the pH value of the solution to 5.5, then add deionized water until the amount of the solution just submerges the activated carbon carrier. . The catalyst active component solution is impregnated with the carrier, aged for 24 hours, then reduced with sodium formate solution, then washed with pure water until neutral and dried to obtain a catalyst product. The initial a...

Embodiment 2~9

[0023] Catalysts were prepared according to the various steps and operating conditions of Example 1, only the type of pre-dipping solution, solution concentration, dipping temperature, dipping time, and drying temperature were changed. See Table 1 for details. The physical properties and evaluation results of the prepared catalysts are shown in Table 2. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com