Preparation method of polymer/graphene/carbon nanometer tube composite material

A technology of carbon nanotubes and composite materials, which is applied in the field of preparation of conductive polymer composite materials, can solve problems such as the inability to effectively regulate the conductive pathway of graphene-carbon nanotubes, affect the comprehensive performance of composite materials, and affect the construction of conductive pathways. Overcoming the difficulty of forming a continuous conductive network, simple and easy processing technology, good operability and repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Preparation of graphene suspension: 0.5 g of graphite oxide was ultrasonically dispersed in water, and centrifuged to obtain a brown-yellow graphene oxide suspension; 140 μL of ammonia water and 20 μL of hydrazine hydrate were added for chemical reduction to prepare a graphene suspension.

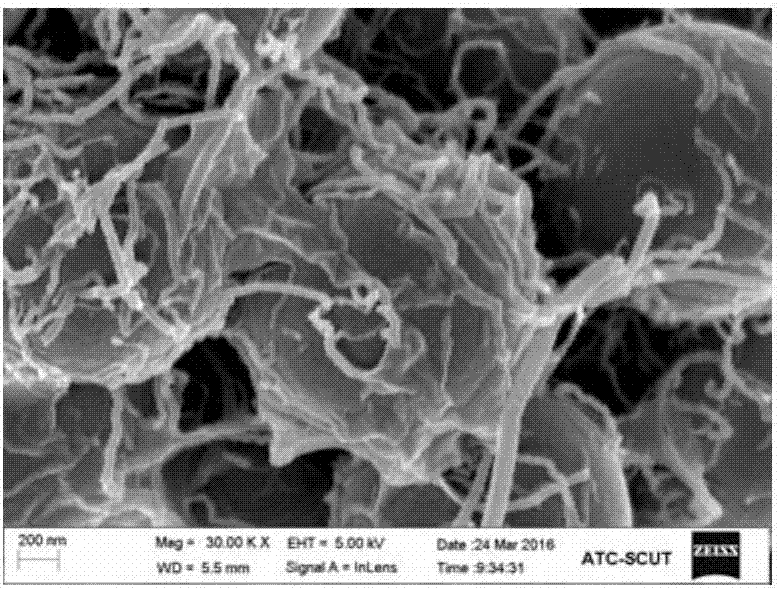

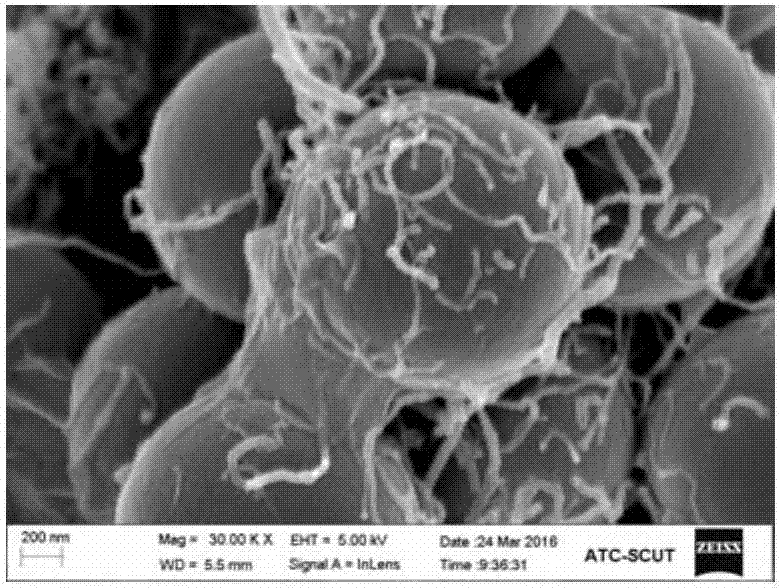

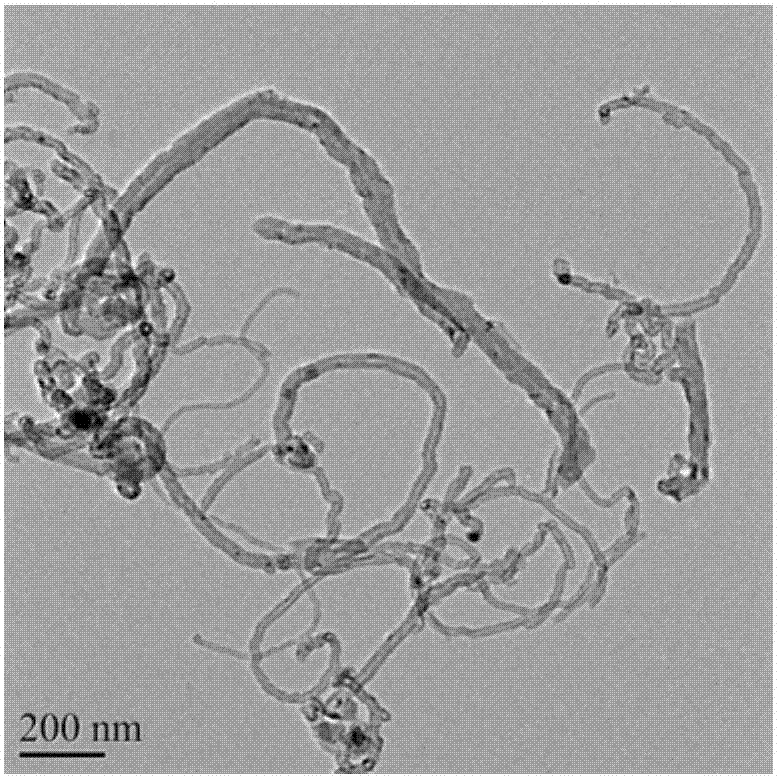

[0029] (2) Preparation of polystyrene microspheres / graphene / carbon nanotube ternary hybrids: ultrasonically disperse 0.075g graphene, 0.1g carbon nanotubes and 6.0g polystyrene microspheres in an aqueous hydrochloric acid solution with pH=1.5 , respectively, to obtain a uniformly dispersed suspension. Mix the three suspensions evenly, and disperse them ultrasonically for 1 hour; adjust the mixed solution to pH=6 by adding 1mol / L sodium hydroxide solution dropwise, and the graphene and carbon nanotubes will be evenly coated on the polystyrene microspheres due to electrostatic adsorption. On the spherical surface, a polystyrene / graphene / carbon nanotube ternary hybrid was prepared. ...

Embodiment 2

[0033] (1) Preparation of graphene suspension: 0.5 g of graphite oxide was ultrasonically dispersed in water, and centrifuged to obtain a brown-yellow graphene oxide suspension; 140 μL of ammonia water and 20 μL of hydrazine hydrate were added for chemical reduction to prepare a graphene suspension.

[0034](2) Preparation of polystyrene microspheres / graphene / carbon nanotube ternary hybrids: ultrasonically disperse 0.1g graphene, 0.128g carbon nanotubes and 9.0g polystyrene microspheres in an aqueous hydrochloric acid solution with pH=2.0 , respectively, to obtain a uniformly dispersed suspension. Mix the three suspensions evenly and disperse them ultrasonically for 1.5 hours; adjust the mixed solution to pH=6 by adding 1mol / L sodium hydroxide solution dropwise, and graphene and carbon nanotubes will be evenly coated on polystyrene due to electrostatic adsorption On the surface of microspheres, polystyrene / graphene / carbon nanotube ternary hybrids were prepared.

[0035] (3) P...

Embodiment 3

[0038] (1) Preparation of graphene suspension: 0.5 g of graphite oxide was ultrasonically dispersed in water, and centrifuged to obtain a brown-yellow graphene oxide suspension; 140 μL of ammonia water and 20 μL of hydrazine hydrate were added for chemical reduction to prepare a graphene suspension.

[0039] (2) Preparation of polystyrene microspheres / graphene / carbon nanotube ternary hybrids: ultrasonically disperse 0.1g graphene, 0.125g carbon nanotubes and 10.0g polystyrene microspheres in an aqueous hydrochloric acid solution with pH=2.5 , respectively, to obtain a uniformly dispersed suspension. Mix the three suspensions evenly, and disperse them ultrasonically for 2.0 hours; adjust the mixed solution to pH=6 by adding 1mol / L sodium hydroxide solution dropwise, and graphene and carbon nanotubes will be uniformly coated on polystyrene due to electrostatic adsorption On the surface of microspheres, polystyrene / graphene / carbon nanotube ternary hybrids were prepared.

[0040]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com