Preparation method of special type titanium dioxide pigment for plastic color master batch

A technology of titanium dioxide and color masterbatch, which is applied in chemical instruments and methods, inorganic pigment treatment, dyeing organosilicon compound treatment, etc., can solve the problems of dry powder fluidity, dispersibility, processing and plasticizing properties that cannot meet plastic color masterbatches, etc. Achieve the effect of improving the photochemical activity of shielding titanium dioxide, wide application prospects, and excellent comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

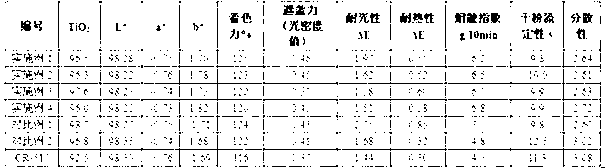

Examples

Embodiment 1

[0025] 1. Weigh 400g of the primary chloride-process rutile titanium dioxide powder with an alumina content of 0.6% and a D50 of 0.22μm, and add 800mL of deionized water to prepare a titanium dioxide slurry. Use a pH meter to detect the pH of the slurry during the entire coating process value; adjust slurry pH to 9.0 with sodium hydroxide solution, add sodium hexametaphosphate solution 8mL, the concentration of sodium hexametaphosphate solution is P 2 o 5 Calculated as 50g / L, dispersed for 20min;

[0026] 2. Grinding the dispersed titanium dioxide slurry, after grinding, the particle size D50 of the titanium dioxide slurry is 350nm and D90 is 620nm, and the grinding medium is removed from the water slurry;

[0027] 3. Heat the ground slurry to 50°C and maintain this temperature throughout the coating process;

[0028] 4. Add 100mL of sodium metaaluminate and potassium metaaluminate mixed aluminum salt solution within 0.5h, the concentration of sodium metaaluminate solution a...

Embodiment 2

[0033] 1. Weigh 400g of the primary chloride-process rutile titanium dioxide powder with an alumina content of 0.9% and a D50 of 0.24μm, add 700mL of deionized water to prepare a titanium dioxide slurry, and use a pH meter to detect the pH value of the slurry during the entire coating process , adjust the slurry pH to 10.0 with sodium hydroxide solution, add sodium pyrophosphate solution 8mL, the concentration of sodium pyrophosphate solution is P 2 o 5 Calculated as 150g / L, dispersed for 25min;

[0034] 2. Grinding the dispersed titanium dioxide slurry, after grinding, the particle size D50 of the titanium dioxide slurry is 300nm and D90 is 600nm, and the grinding medium is removed from the water slurry;

[0035] 3. Heat the ground slurry to 60°C and maintain this temperature throughout the coating process;

[0036] 4. Add 53mL of sodium metaaluminate solution within 1.0h, the concentration of sodium metaaluminate solution is Al 2 o 3 Calculated as 150g / L, at the same tim...

Embodiment 3

[0041] 1. Weigh 400g of the chloride-process rutile titanium dioxide primary powder with an alumina content of 1.2% and a D50 of 0.25μm, add 600mL of deionized water to prepare a titanium dioxide slurry, and use a pH meter to detect the pH value of the slurry during the entire coating process , adjust the slurry pH to 10.0 with sodium hydroxide solution, add sodium pyrophosphate and trisodium phosphate mixed phosphate solution 12mL, the concentration of sodium pyrophosphate solution and trisodium phosphate solution is P 2 o 5 The total is 100g / L, dispersed for 20min;

[0042] 2. Grinding the dispersed titanium dioxide slurry, after grinding, the particle size D50 of the titanium dioxide slurry is 360nm and D90 is 680nm, and the grinding medium is removed from the water slurry;

[0043]3. Heat the ground slurry to 70°C and maintain this temperature throughout the coating process;

[0044] 4. Add 33mL of aluminum trichloride solution within 1.5h, the concentration of aluminum ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com