Preparation method of calcium hydroxide/graphene nano composite material

A technology of nanocomposite material and calcium hydroxide, applied in the field of preparation of calcium hydroxide/graphene nanocomposite material, can solve the problems such as the inability to give full play to the dispersing effect of graphene, achieve easy industrialized mass production, prevent agglomeration, and reaction conditions mild effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Add 100 mg of graphene powder and 600 mg of sodium chlorate to 50 mL of concentrated sulfuric acid, and stir for 6 hours in an ice bath.

[0024] (2) Centrifugally clean the modified functionalized graphene and dry to obtain a powder. Add the powder to the aqueous solution and ultrasonicate for 1 hour to obtain a 1 mg / mL functionalized graphene aqueous dispersion.

[0025] (3) Add 10 mmol of calcium chloride to the functionalized graphene dispersion, stir at room temperature for 1 hour, and after mixing is uniform, continue to stir and heat to 90°C.

[0026] (4) Add 1 mmol / mL sodium hydroxide solution dropwise to the solution at a rate of 1 mL / min, add 12 mL in total, and continue to keep the temperature for 30 minutes after the addition is complete.

[0027] (5) After centrifugal water washing and vacuum drying, heat treatment at 400°C for 1 h in a protective atmosphere to obtain calcium hydroxide / graphene nanocomposite powder.

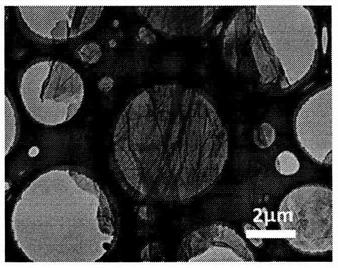

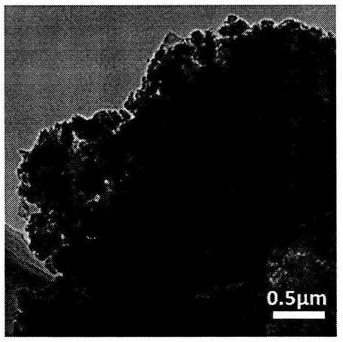

[0028] figure 1 The TEM image of the function...

Embodiment 2

[0031] (1) Add 100 mg of graphene powder and 800 mg of sodium chlorate to 50 mL of concentrated sulfuric acid, and stir for 6 hours in an ice bath.

[0032] (2) Centrifugally clean the modified functionalized graphene and dry to obtain a powder. Add the powder to the aqueous solution and ultrasonicate for 1 hour to obtain a 1 mg / mL functionalized graphene aqueous dispersion.

[0033] (3) Add 10 mmol of calcium chloride to the functionalized graphene dispersion, stir at room temperature for 1 hour, and after mixing is uniform, continue to stir and heat to 90°C.

[0034] (4) Add 1 mmol / mL sodium hydroxide solution dropwise to the solution at a rate of 1 mL / min, add 12 mL in total, and continue to keep the temperature for 30 minutes after the addition is complete.

[0035] (5) After centrifugal water washing and vacuum drying, heat treatment at 400°C for 1 h in a protective atmosphere to obtain calcium hydroxide / graphene nanocomposite powder.

Embodiment 3

[0037] (1) Add 100 mg of graphene powder and 600 mg of sodium chlorate to 50 mL of concentrated sulfuric acid, and stir for 6 hours in an ice bath.

[0038] (2) Centrifugal cleaning the modified functionalized graphene, drying to obtain powder, adding the powder to the aqueous solution, and sonicating for 1 hour to obtain a 0.5 mg / mL functionalized graphene aqueous dispersion.

[0039] (3) Add 10 mmol of calcium chloride to the functionalized graphene dispersion, stir at room temperature for 1 hour, and after mixing is uniform, continue to stir and heat to 90°C.

[0040] (4) Add 1 mmol / mL sodium hydroxide solution dropwise to the solution at a rate of 1 mL / min, add 12 mL in total, and continue to keep the temperature for 30 minutes after the addition is complete.

[0041] (5) After centrifugal water washing and vacuum drying, heat treatment at 400°C for 1 h in a protective atmosphere to obtain calcium hydroxide / graphene nanocomposite powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com