Novel aqueous dispersant and preparation method thereof, and application of novel aqueous dispersant to dispersion containing solid particles

An aqueous dispersant, solid particle technology, applied in chemical instruments and methods, organic dyes, dissolution, etc., can solve the problems of small molecular weight, weak anchoring ability of solid particles, and inability to provide steric hindrance for solid particles, and achieves high molecular weight, Strong anchoring ability and the effect of improving dispersion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

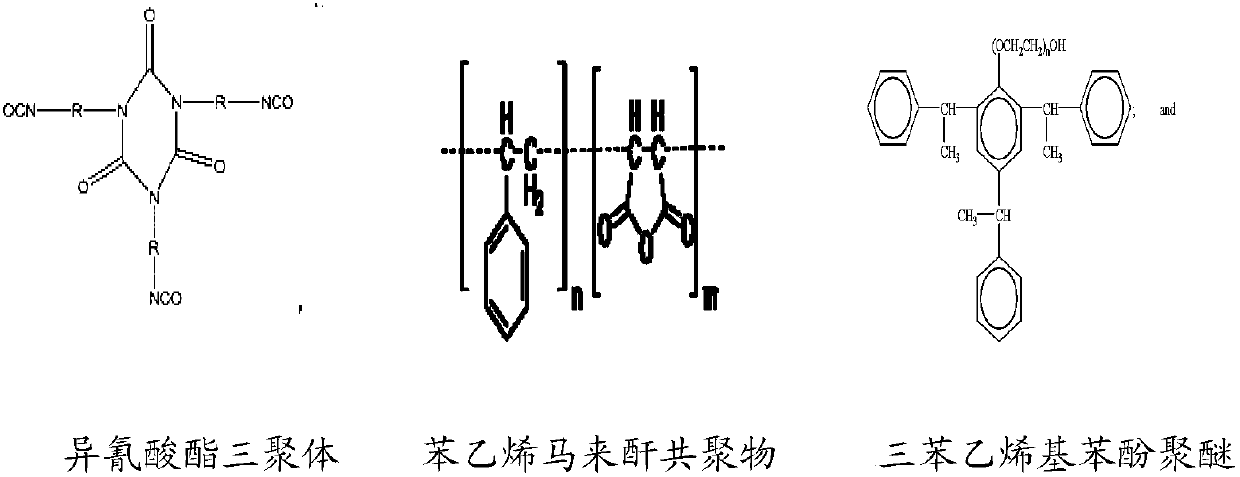

[0035] A new type of water-based dispersant, the dispersant contains a single hydroxyl polyether chain, and a comb-shaped polyphenylene ring molecular structure; the single hydroxyl polyether chain and the comb-shaped polyphenylene ring molecular body connection.

Embodiment 2

[0037] A new type of water-based dispersant, the dispersant contains a primary amine functional group polyether chain, and a comb-type polyphenylene ring molecular structure; the polyether chain and the comb-type polyphenylene ring molecular structure are passed through styrene Anhydride copolymer Sartomer SMA1000 connection.

Embodiment 3

[0039] Preparation of intermediate A-isocyanate: under nitrogen, add monohydroxy polyoxyethylene ether (molecular weight 1000, 330 parts, 0.33mol) dropwise to the trimer of hexamethylene diisocyanate Desmodur N3300 (192.6 parts, -NCO %=21.8%) at 70°C for 1 hour to obtain intermediate A.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com