Method for preparing polypropylene composite parent material containing inorganic material for use on polypropylene fibers

A polypropylene fiber and inorganic material technology, applied in the field of textiles, can solve the problems of unreported preparation methods, and achieve the effects of improving spinnability, reducing production costs, and improving dispersion performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

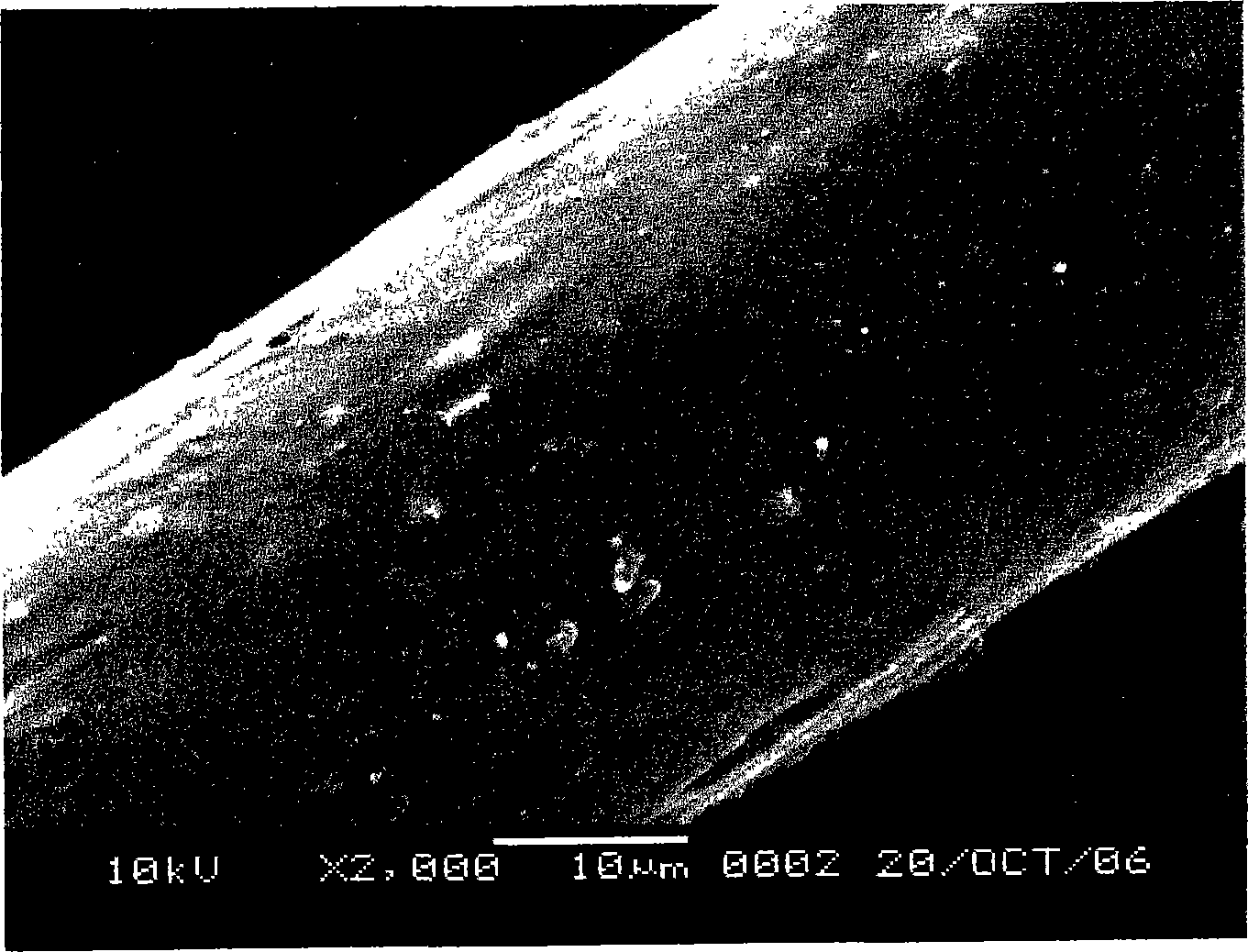

Image

Examples

Embodiment 1

[0039] In a 10-liter high-speed mixer (SHR-10A, the same below), add 720 grams of light calcium carbonate with a particle diameter of 60-90nm and 1080 grams of heavy calcium carbonate with a particle diameter of 70%≤3 μm, turn on high speed, stir and heat up to Keep at 110°C for 10 minutes to remove moisture. Add the stearic acid of 3.6 grams, stop after stirring for 15 minutes, be cooled to below 70 ℃. Then add 36 grams of aluminate coupling agent, stir at high speed for 20 minutes, and stop. Add 1200 grams of Y3700pp, 25 grams of polysiloxane, 8 grams of antioxidant 1010, 16 grams of antioxidant 168, 9 grams of calcium stearate, 120 grams of polypropylene wax, and 9 grams of HE86, and take it out after stirring for 10 minutes. Bagging.

Embodiment 2

[0041] In a 10-liter high-speed mixer, add 300 grams of light calcium carbonate with a particle size of 60-90nm and 1200 grams of heavy calcium carbonate with a particle size of 70%≤3μm, stir and heat up to 110°C for 10 minutes, and then add 4.5 grams of calcium carbonate Stearic acid, stirring stopped after 20 minutes. After cooling to below 70°C, 18 grams of titanate coupling agent was added, and the stirring was stopped after 15 minutes. Add 120 grams of maleic anhydride grafted pp, 1200 grams of Y3700pp, 20 grams of ethylene bis stearic acid amide, 8 grams of antioxidant 1010, 8 grams of antioxidant 168, 9 grams of calcium stearate, 377 grams of polypropylene wax , 6 grams of HE86, stirred for 10 minutes and removed. Bagging.

Embodiment 3

[0043]In a 10-liter high-speed mixer, add 625 grams of light calcium carbonate with a particle size of 60-90nm and 1875 grams of heavy calcium carbonate with a particle size of 80%≤1.6μm, stir and heat up to 110°C for 10 minutes, and then add 5.4 grams Stearic acid, stop stirring after 15 minutes, and cool to below 70°C. Then add 188 grams of nano-montmorillonite with a lamination thickness of less than 25 nm and a diameter / thickness ratio of 200, and 85 grams of aluminate coupling agent, and stir at high speed for 20 minutes before stopping. Add 1250 grams of S2040pp, 250 grams of polyethylene wax, 150 grams of polypropylene wax, 8 grams of antioxidant 1010, 8 grams of antioxidant 168, 19 grams of silicone lubricant, 8 grams of zinc stearate. Remove after stirring for 8 minutes. Bagging.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com