Concrete curing compound and preparation method thereof

A technology of concrete curing agent and dispersing agent, applied in the field of building materials, can solve the problems of affecting the appearance quality of concrete, unable to effectively prevent efflorescence of concrete capillary pores, etc., to increase the film-forming and curing effect, increase the curing effect, and improve the dispersion performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

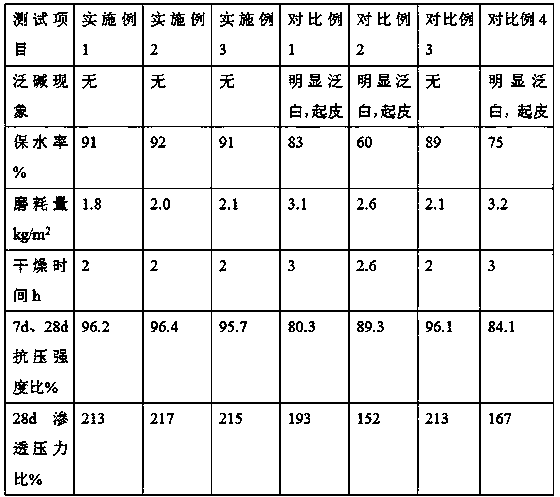

Examples

preparation example Construction

[0028] The preparation method of modified particles is as follows:

[0029] (1) According to the mass ratio of 6:4 to 9:5, put sepiolite, nano-silicon dioxide and nano-titanium dioxide into a ball mill for 50 minutes at 900r / min, collect the ball-milled material, and the mass fraction of the ball-milled material is 98 % sulfuric acid is mixed and soaked for 2 hours according to the mass ratio of 4-6:13, filtered, and the filter residue is collected, washed until neutral, and dried to obtain pre-modified particles;

[0030] (2) In parts by mass, take 90-95 parts of sodium hydroxide solution, 20-25 parts of ferric nitrate, 10-15 parts of ferrous nitrate, 7-9 parts of succinic acid, 3-9 parts of 4,4-linked Pyridine, 1-3 parts of ethylenediamine, sodium hydroxide solution, ferric nitrate, ferrous nitrate, and succinic acid are put into the reactor, and oxygen is introduced from the bottom of the reactor at 900mL / min, and the set temperature is 60-65°C , stirred and reacted for 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com