Three-dimensional printing material based on modification of gypsum base powder

A 3D printing and gypsum powder technology, applied in the field of 3D printing, can solve the problems of affecting printing efficiency and printing accuracy, affecting the quality of printed molding products, and poor fluidity of powder materials, achieving good printing accuracy, promoting hardening effect, and compressive strength Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

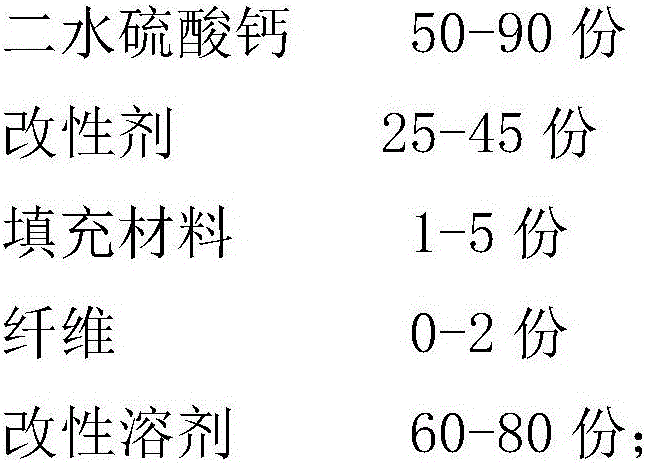

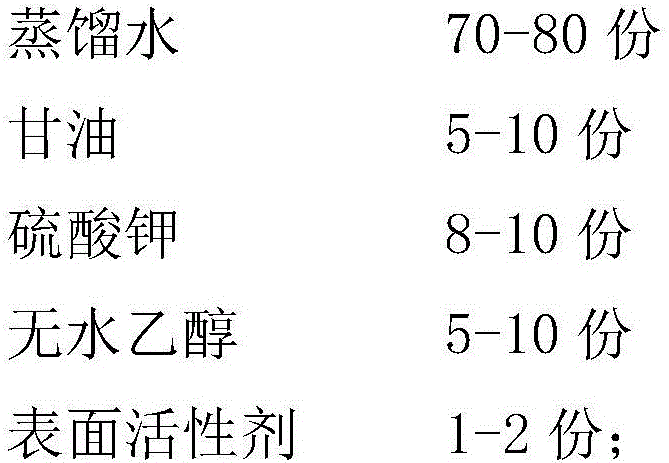

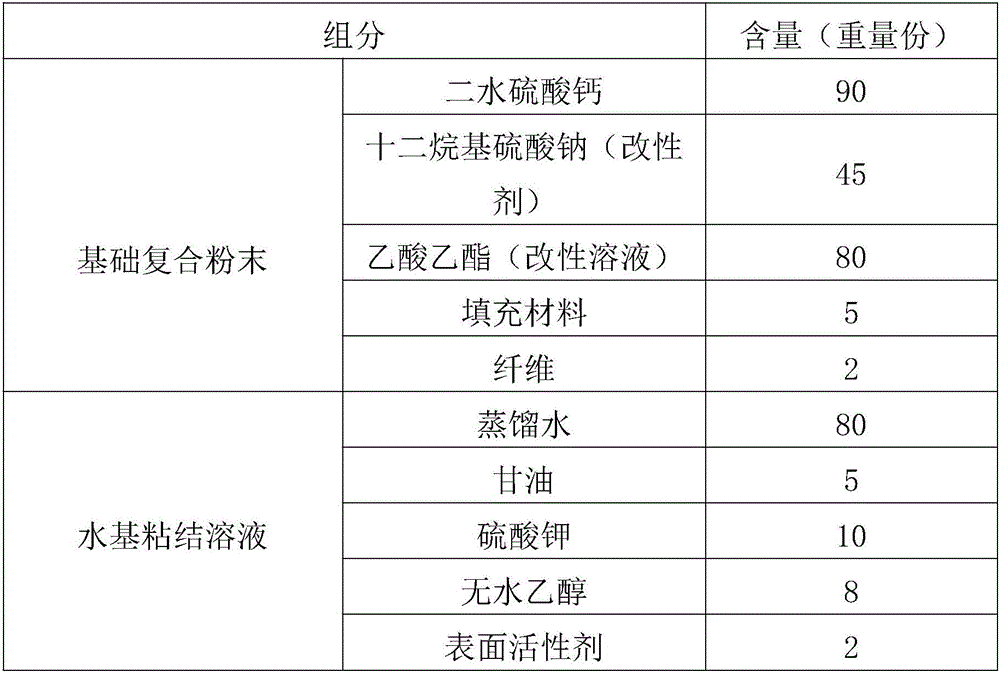

[0026] A 3D printing material is disclosed in Example 1, and the composition of the material is shown in Table 1.

[0027] Formulation table in table 1 embodiment 1

[0028]

Embodiment 2

[0030] The formula composition of the printing material in embodiment 2 is as shown in table 2,

[0031] Formulation table in table 2 embodiment 2

[0032]

[0033]

[0034] The difference between embodiment 2 and embodiment 1 is that the modifying agent is different. The coagulation-accelerating modifying agent is selected as a kind of organic high polymer in embodiment 2, and its average molecular weight is 200-6000, and it is verified by many groups of comparative experiments. When the molecular weight is 600, the powder rollability and dispersibility of the material are better. Therefore, in the following examples, the coagulation accelerator modifier with a molecular weight of 600 is used as an example.

[0035] The above-mentioned modifier can also choose stearic acid. Compared with stearic acid, sodium eicosyl sulfate and coagulation accelerator modifier, the calcium sulfate powder particles modified by the coagulation accelerator modifier have better rolling prop...

Embodiment 3

[0037] The formulation in Example 3 is shown in Table 3.

[0038] Formulation table in table 3 embodiment 3

[0039]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com