Silicone composition

A technology of silicone and composition, applied in the field of cross-linkable silicone composition, can solve the problems of poor anti-foaming performance, high viscosity of silicone polymer, single structure, etc., achieve good anti-foaming performance, enhance application performance, the effect of improving foam suppression performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

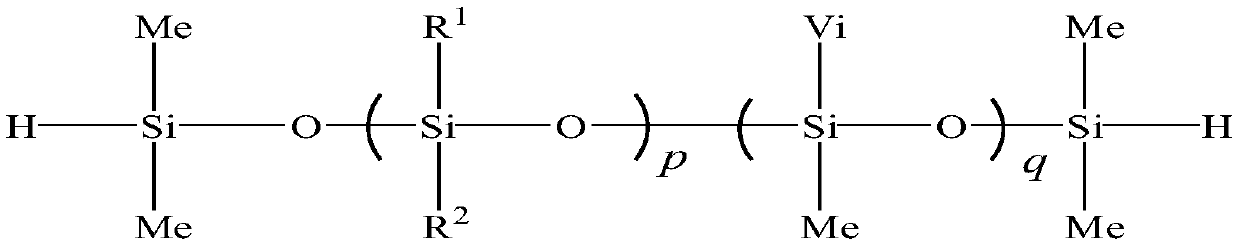

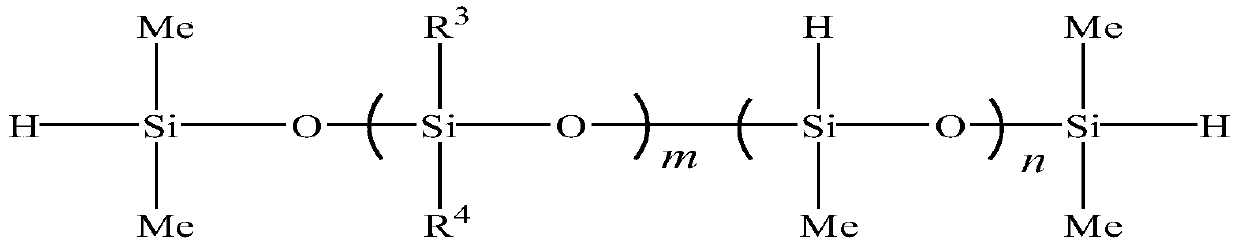

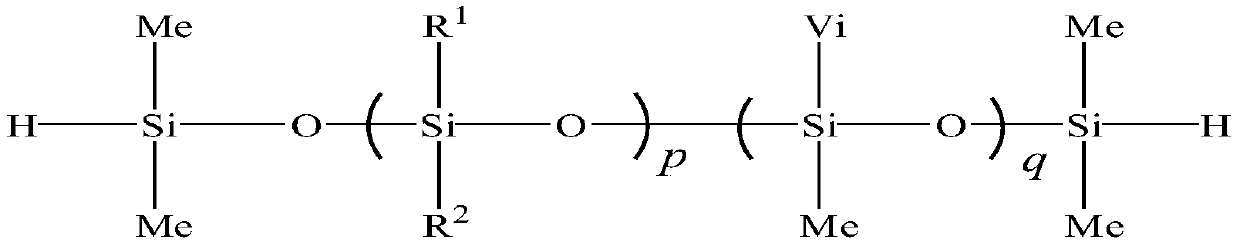

Method used

Image

Examples

Embodiment 1

[0038] (1) Add 100g of (Me) with a viscosity of 90mPa.s into the reactor 2 HSiO(Me 2 SiO) 50 (MeHSiO) 20 SiH(Me) 2 , 40g of silicone resin (M:Q=0.5:1.0), 493g of polymethylsiloxane with a viscosity of 500mPa.s, 12g of CH 2 =CHCH 2 (EO) 20 (PO) 60 Unsaturated polyether of H; mix well and heat up to 50°C, add 0.005g of 1% chloroplatinic acid isopropanol solution, keep warm at 50°C and continue to react for 2 hours, then add 300g of H(Me) with a viscosity of 3000mPa.s 2 SiO(Me 2 SiO) 500 (MeViSiO) 40 SiH(Me) 2 , mix well and continue to react at 50°C for 2h; (2) Continue to add 14.995g of potassium hydroxide-isopropanol solution to the composition of step (1), and raise the temperature to 100°C for 1h; keep warm and add 40g specific surface area of 300m 2 / g of precipitated hydrophobic silica, mixed and stirred, continued to react at 100°C for 1 h, cooled to room temperature, and obtained organosilicon composition S1.

Embodiment 2

[0040] (1) Add 50g of (Me) with a viscosity of 500mPa.s into the reactor 2 HSiO(Me 2 SiO) 200 (MeHSiO) 30 SiH(Me) 2 , 80g of silicone resin (M:Q=0.8:1.0), 400g of polymethylsiloxane with a viscosity of 2000mPa.s, 10g of CH 2 =CHCH 2 (EO) 40 (PO) 30 Unsaturated polyether of H; mix well and add 0.01g of 1% isopropanol solution of chloroplatinic acid when the temperature rises to 50°C, continue to heat up to 90°C and react for 1 hour, then add 400g of H(Me) with a viscosity of 100,000mPa.s 2 SiO(Me 2 SiO) 1500 (MeViSiO) 300 SiH(Me) 2 , mix well and continue to react at 90°C for 0.5h; (2) step (1) continue to add 10g potassium hydroxide-isopropanol solution to the composition, and raise the temperature to 140°C for 30min; keep warm and add 49.99g specific surface area of 500m 2 / g of fumed hydrophobic silica, mixed and stirred, continued to react at 140°C for 30min, cooled to room temperature, and obtained organosilicon composition S2.

Embodiment 3

[0042] (1) Add 190g of (Me) with a viscosity of 40mPa.s into the reactor 2 HSiO(Me 2 SiO) 35 (MeHSiO) 15 SiH(Me) 2 , 40g of silicone resin (M:Q=0.6:1.0), 500g of polymethylsiloxane with a viscosity of 1000mPa.s, 15g of CH 2 =CHCH 2 (EO) (PO) 40 Unsaturated polyether of H; mix well and add 0.008g of 1% isopropanol solution of chloroplatinic acid when the temperature rises to 50°C, continue to heat up to 70°C and react for 0.8h, then add 300g of H(Me) with a viscosity of 5000mPa.s 2 SiO(Me 2 SiO) 600 (MeViSiO) 60 SiH(Me) 2 , mix well and continue to react at 70°C for 1.5h; (2) step (1) continue to add 15.008g of potassium hydroxide-isopropanol solution to the composition, and raise the temperature to 120°C for 0.6h; keep warm and add 40g of specific surface area 50m 2 / g of precipitated hydrophobic silica, mixed and stirred, continued to react at 120°C for 30min, and cooled to room temperature to obtain organosilicon composition S3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com