Preparation method of high water retention type polycarboxylate superplasticizer

A water-retaining polycarboxylic acid technology, which is applied in the field of building materials, can solve the problems of low efficiency in the esterification process, and achieve the effects of high dispersion performance, slump retention and retardation, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

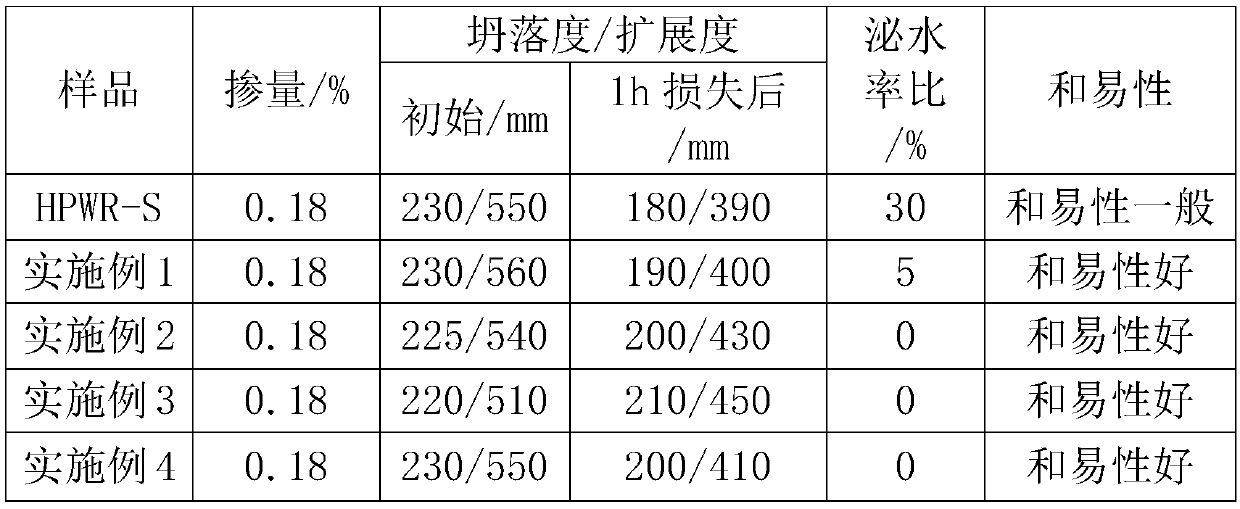

Examples

Embodiment 1

[0024] 1) In parts by mass: 100 parts of acrylic acid, 5 parts of itaconic acid, 5 parts of maleic anhydride and 400 parts of water were mixed, stirred, dissolved and reacted at 75°C, followed by adding 0.8 parts of hydrogen peroxide, and then dripping 300 parts of acrylic acid , 10 parts of hydroxyethyl acrylate, 1.0 parts of 3-mercaptopropionic acid, 0.5 parts of L-ascorbic acid and 200 parts of water are added dropwise in 2.0 hours. part of toluoyloxy-2,2,6,6-tetramethylpiperidine to obtain a main chain copolymer intermediate, wherein the molecular weight of the main chain copolymer intermediate is 5000-30000;

[0025] 2) in parts by mass: 70 parts of molecular weight are 750 polyethylene glycol monomethyl ether, 10 parts of glucose, 35 parts of main chain copolymer intermediate and 0.1 part of concentrated sulfuric acid prepared in step 1) are mixed, and the temperature is raised to 150°C, start stirring and vacuumize at the same time to react for 5 hours under a vacuum of...

Embodiment 2

[0027] 1) In parts by mass: 100 parts of acrylic acid, 5 parts of itaconic acid, 5 parts of maleic anhydride and 400 parts of water were mixed, stirred, dissolved and reacted at 75°C, followed by adding 0.8 parts of hydrogen peroxide, and then dripping 300 parts of acrylic acid , 10 parts of hydroxyethyl acrylate, 1.0 parts of 3-mercaptopropionic acid, 0.5 parts of L-ascorbic acid and 200 parts of water are added dropwise in 2.0 hours. part of toluoyloxy-2,2,6,6-tetramethylpiperidine to obtain a main chain copolymer intermediate, wherein the molecular weight of the main chain copolymer intermediate is 5000-30000;

[0028] 2) in parts by mass: 70 parts of molecular weight is 750 polyethylene glycol monomethyl ether, 20 parts of glucose, 35 parts of main chain copolymer intermediate and 0.15 part of concentrated sulfuric acid prepared in step 1) are mixed, and the temperature is raised to 155°C, start stirring and vacuumize at the same time to react for 6 hours under a vacuum of...

Embodiment 3

[0030] 1) In parts by mass: 100 parts of acrylic acid, 10 parts of itaconic acid, 10 parts of maleic anhydride and 400 parts of water were mixed, stirred, dissolved and reacted at 75°C, followed by adding 0.8 parts of hydrogen peroxide, and then dripping 270 parts of acrylic acid , 20 parts of hydroxyethyl acrylate, 1.0 part of 3-mercaptopropionic acid, 0.5 part of L-ascorbic acid and 200 parts of water, and the mixed solution was added dropwise in 2.0 hours. part of toluoyloxy-2,2,6,6-tetramethylpiperidine to obtain a main chain copolymer intermediate, wherein the molecular weight of the main chain copolymer intermediate is 5000-30000;

[0031] 2) In parts by mass: 70 parts of polyethylene glycol monomethyl ether with a molecular weight of 750, 20 parts of glucose, 35 parts of the main chain copolymer intermediate prepared in step 1) and 0.2 part of p-toluenesulfonic acid were mixed, Raise the temperature to 150°C, start stirring and vacuumize at the same time to react for 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com