Enhanced epoxy asphalt binder and preparation method thereof

A technology of epoxy asphalt and binder, which is applied in the direction of asphalt material adhesive, epoxy resin glue, adhesive, etc. Low problems such as ensuring long-term phase structure stability, inhibiting phase separation, and increasing compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

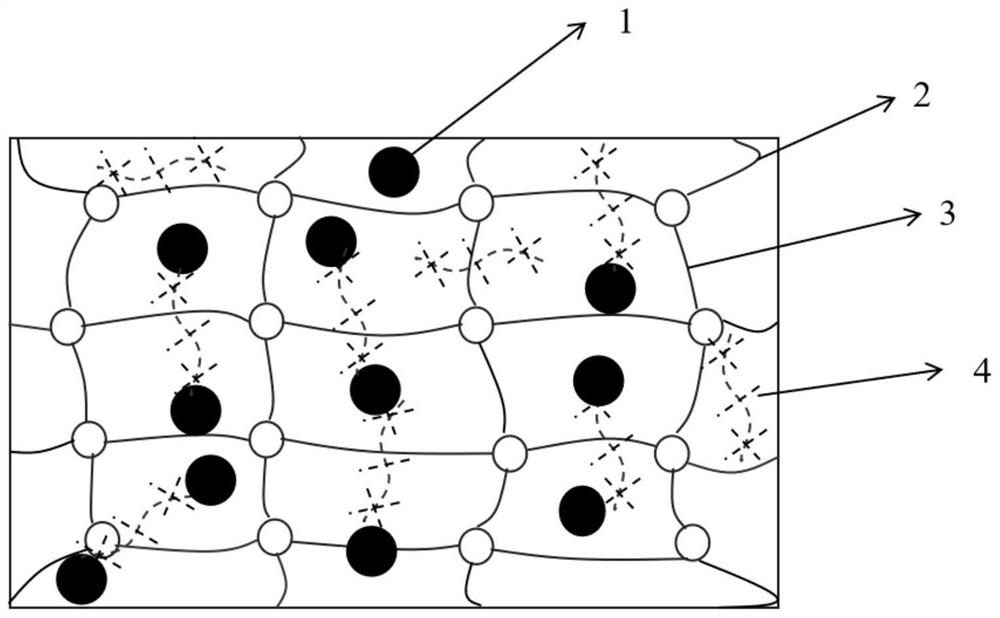

Image

Examples

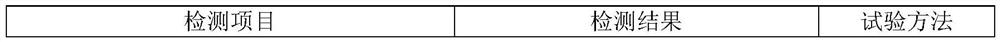

Embodiment 1

[0052] Embodiment 1: a kind of reinforced epoxy asphalt binder and preparation method thereof

[0053] The reinforced epoxy asphalt binder provided in this example, calculated in parts by weight, component A includes: 95 parts E51, 5 parts XY622, 1 part SCA-E87M, 75 parts I-modified asphalt, 25 parts Epoxy fatty acid methyl ester; component B includes: 80 parts of oleylamine and 20 parts of S-3815; the mass ratio between component A and component B is 100:100.

[0054] The preparation process of the reinforced epoxy asphalt binder is as follows:

[0055] S1 Preheat Type I modified asphalt to 120°C, add epoxy fatty acid methyl ester preheated to 60°C, and stir at 30rpm for 60min to form a homogeneous liquid A 1 ;

[0056] S2 Preheat E51 to 60°C, add XY622 and SCA-E87M, and stir at 30rpm for 60min to form a homogeneous liquid A 2 ;

[0057] S3 will A 1 add to A 2 In, the A component is formed after high-speed shearing at 2000rpm for 2h;

[0058] S4: Preheat oleylamine to ...

Embodiment 2

[0064] Embodiment 2: a kind of reinforced epoxy asphalt binder and preparation method thereof

[0065] The reinforced epoxy asphalt binder provided in this example, calculated in parts by weight, component A includes: 80 parts E20, 20 parts XY692, 1 part SCA-E87E, 25 parts II modified asphalt, 25 parts Epoxy fatty acid octyl ester; component B includes: 95 parts of coconut amine and 5 parts of OA9; the mass ratio between component A and component B is 100:50.

[0066] The preparation process of the reinforced epoxy asphalt binder is as follows:

[0067] S1 Preheat Type II modified asphalt to 140°C, add epoxy fatty acid octyl ester preheated to 60°C, and stir at 60 rpm for 30 minutes to form a homogeneous liquid A 1 ;

[0068] S2 Preheat E20 to 60°C, add XY692 and SCA-E87E, and stir at 60rpm for 30min to form a homogeneous liquid A 2 ;

[0069] S3 will A 1 add to A 2 , the A component is formed after high-speed shearing at 4000rpm for 1h;

[0070] S4 preheats cocoamine t...

Embodiment 3

[0076] Embodiment 3: a kind of reinforced epoxy asphalt binder and preparation method thereof

[0077]The reinforced epoxy asphalt binder provided in this example, calculated in parts by weight, component A includes: 90 parts E44, 10 parts XY748, 3 parts SCA-E87F, 37.5 parts II type modified asphalt, 12.5 parts Epoxy fatty acid butyl ester; component B includes: 90 parts of N-oleyl propylene diamine and 10 parts of S-1017; the mass ratio between component A and component B is 100:67.

[0078] The preparation process of the reinforced epoxy asphalt binder is as follows:

[0079] S1 Preheat Type II modified asphalt to 130°C, add epoxy fatty acid butyl ester preheated to 60°C, and stir at 30 rpm for 60 minutes to form a homogeneous liquid A 1 ;

[0080] S2 Preheat E44 to 60°C, add XY748 and SCA-E87F, and stir at 30rpm for 60min to form a homogeneous liquid A 2 ;

[0081] S3 will A 1 add to A 2 , the A component was formed after high-speed shearing at 3000rpm for 1.5h;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com