Preparation method of 4-selenomethoxynaphthalene

A technology of selenomethoxynaphthalene and methoxynaphthalene, which is applied in the direction of organic chemistry to achieve the effects of low reaction cost, high yield and short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

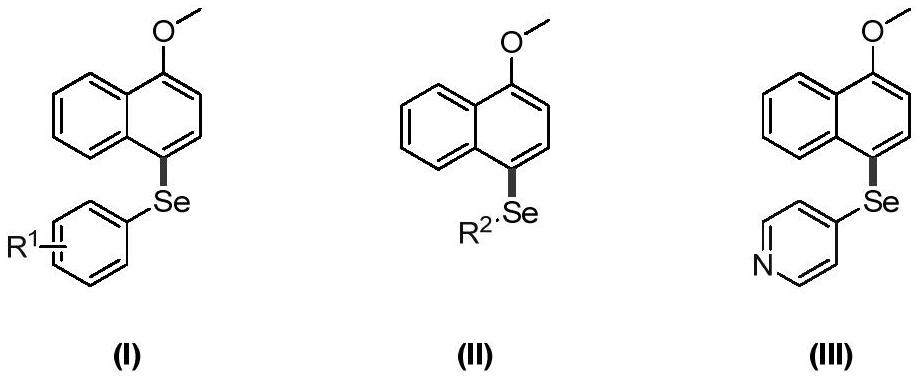

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

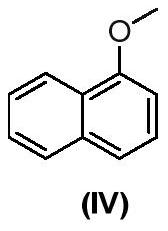

[0025] Add 1-methoxynaphthalene (0.2mmol), 1,2-diphenyldiselenide (0.4mmol), PIFA (0.2mmol) and DCM (2.0mL) respectively into a 4mL reaction flask, and stir at room temperature. TLC tracking detection reaction. After 10 minutes, the reaction was complete. Water and dichloromethane were added to the reaction system, and the organic layer was separated. The aqueous layer was washed twice with dichloromethane, all organic layers were combined and washed twice with water. The organic layer was dried over anhydrous sodium sulfate, concentrated, and separated by column chromatography (5% ethyl acetate petroleum ether solution) to obtain 50.1 mg of product with a yield of 80%. The reaction process is shown in the following formula:

[0026]

[0027] Carry out nuclear magnetic resonance analysis to the product that present embodiment prepares: 1 H NMR (400MHz, CDCl 3 )δ8.36–8.31(m,2H),7.90(d,J=8.0Hz,1H),7.55–7.49(m,2H),7.23–7.21(m,2H),7.17–7.12(m,3H) ,6.80(d,J=8.0Hz,1H),4.04(s...

Embodiment 2

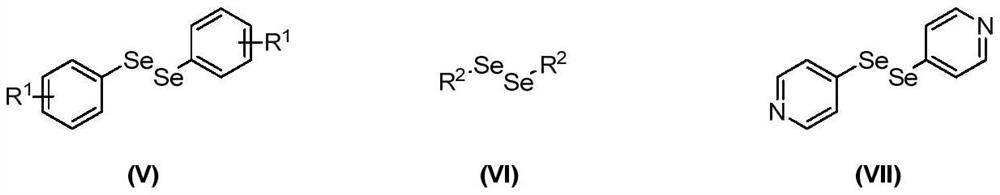

[0029] Add 1-methoxynaphthalene (0.2mmol), 1,2-diphenyldiselenide (0.4mmol), PIFA (0.4mmol) and DCM (2.0mL) respectively into a 4mL reaction flask, and stir at room temperature. TLC tracking detection reaction. After 5 hours, the reaction was complete. Water and dichloromethane were added to the reaction system, and the organic layer was separated. The aqueous layer was washed twice with dichloromethane, all organic layers were combined and washed twice with water. The organic layer was dried over anhydrous sodium sulfate, concentrated, and separated by column chromatography (5% ethyl acetate petroleum ether solution) to obtain 50.1 mg of product with a yield of 80%. The reaction process is shown in the following formula:

[0030]

Embodiment 3

[0032] Add 1-methoxynaphthalene (0.2mmol), 1,2-diphenyldiselenide (0.24mmol), PIFA (0.4mmol) and DCM (2.0mL) respectively into a 4mL reaction flask, and stir at room temperature. TLC tracking detection reaction. After 1.5 hours, the reaction was complete. Water and dichloromethane were added to the reaction system, and the organic layer was separated. The aqueous layer was washed twice with dichloromethane, all organic layers were combined and washed twice with water. The organic layer was dried over anhydrous sodium sulfate, concentrated, and separated by column chromatography (5% ethyl acetate petroleum ether solution) to obtain 32.6 mg of product with a yield of 52%. The reaction process is shown in the following formula:

[0033]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com