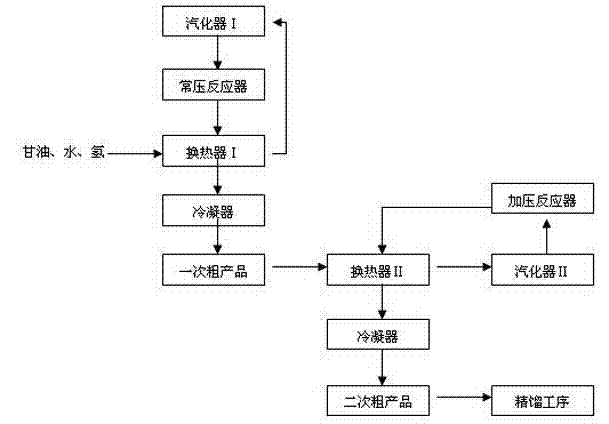

Process for preparing 1,2-propylene glycol from biological glycerol through low-temperature and low-pressure hydrogenation

A low-temperature, low-pressure, propylene glycol technology, applied in the chemical industry, can solve problems such as harsh reaction conditions and complex production processes, and achieve the effects of fast reaction rate, easy operation, high selectivity and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

[0019] Add 15ml Cu-SiO to fixed bed reactors A and B respectively 2 Catalyst, glycerol-water solution at the feed rate of 20g / h, hydrogen at 1200h -1 The space velocity first enters reactor A to complete the first step reaction, and then enters reactor B to complete the second step reaction. The weight ratio of glycerol to water in the raw material solution is 1-4. Both A and B reactors have a reaction temperature of 185°C. The A reactor is at normal pressure, and the B reactor has a reaction pressure of 0.5 MPa. After 5 hours of starting the reaction, samples were taken in the B reactor and analyzed by gas chromatography. The results are shown in Table 1:

[0020] Table 1

[0021] .

Embodiment 5~8

[0023] Add 15ml Cu-SiO to fixed bed reactors A and B respectively 2 Catalyst, glycerol-water solution at the feed rate of 20g / h, hydrogen at 800~14000h -1 The space velocity first enters reactor A to complete the first step reaction, and then enters reactor B to complete the second step reaction. The weight ratio of glycerol to water in the raw material solution was 3. Both A and B reactors have a reaction temperature of 185°C. The A reactor is at normal pressure, and the B reactor has a reaction pressure of 0.5MPa. After 5 hours of starting the reaction, samples were taken in B reactor, and analyzed by gas chromatography. The results are shown in Table 2:

[0024] Table 2

[0025] .

Embodiment 9~15

[0027] Add 15ml Cu-SiO to fixed bed reactors A and B respectively 2 Catalyst, glycerol-water solution at the feed rate of 20g / h, hydrogen at 1000h -1 The space velocity first enters reactor A to complete the first step reaction, and then enters reactor B to complete the second step reaction. The weight ratio of glycerol to water in the raw material solution was 3. The reaction temperature of A and B reactors are both 160-190°C, the A reactor is at normal pressure, and the B reactor has a reaction pressure of 0.3-0.8 MPa. After 5 hours of starting the reaction, samples are taken in B reactor and analyzed by gas chromatography. The results are shown in the table. 3:

[0028] table 3

[0029] .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com