Double-stator double-rotor flameproof motor

An explosion-proof motor, double rotor technology, applied in the direction of electrical components, electromechanical devices, etc., can solve problems such as unsatisfactory, bending deformation of the rotating shaft, poor parameters, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

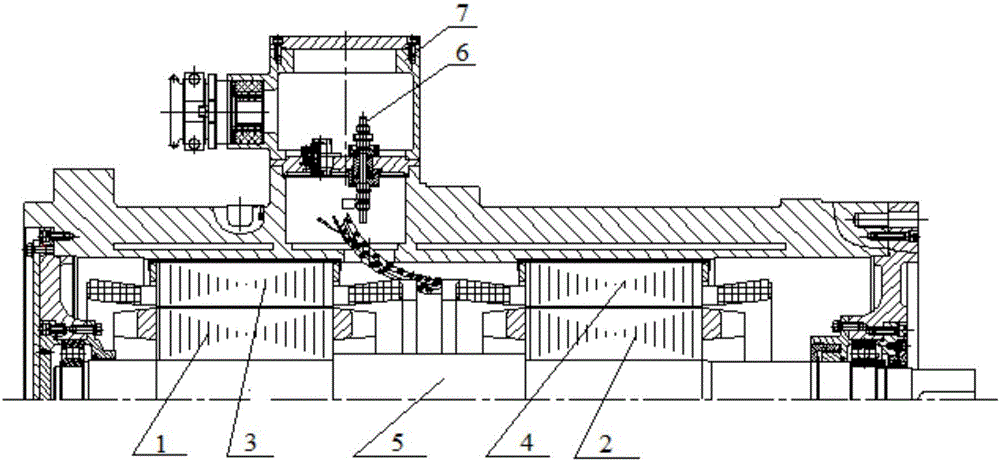

[0017] see figure 1 , double-stator double-rotor flameproof motor, including first rotor 1, second rotor 2, first stator 3, second stator 4, drive shaft 5, terminal 6, junction box 7, housing, end cover and bearing Cover, the first rotor 1 and the second rotor 2 are sequentially connected to the transmission shaft 5, the first stator 3 is set on the first rotor 1, the second stator 4 is set on the second rotor 2, and the terminal 6 is fitted on the In the junction box 7, the end cover and the bearing cover are assembled on the housing, and the three main leads of the winding of the first stator 3 and the three main leads of the winding of the second stator 4 are connected to the terminal 6 in parallel with the same item . There is a wiring gap between the windings of the first stator 3 and the windings of the second stator 4 . The windings of the first stator 3 and the second stator 4 are independent of each other, the windings of the first stator 3 are equipped with tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com