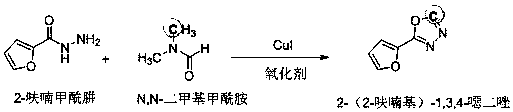

Method for building 2-(2-furyl)-1,3,4-oxadiazole in one step from DMF as carbon source

A furyl and oxadiazole technology, applied in the fields of cell biology, medicine, and materials, can solve the problems of toxic chemical reagents, and achieve the effects of easy-to-obtain reaction raw materials, mild reaction conditions, and novel synthetic routes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] In a 25 mL test tube, add 0.2 mmol of 2-furyl hydrazide, 0.05 mmol of cuprous iodide, and 0.2 mmol of potassium persulfate, add DMF (N,N-dimethylformamide) as a solvent, and dissolve at 120 Stir at ℃. After TLC (thin layer chromatography) detection, the reaction solution was cooled to room temperature, the reaction solution was filtered, extracted, the filtrate was evaporated under reduced pressure to remove the solvent, and then separated and purified by column chromatography to obtain the target product 2-(2-furyl )-1,3,4-oxadiazole, the column chromatography eluent used was a mixture of petroleum ether:ethyl acetate with a volume ratio of 3:1, and the yield was 40%.

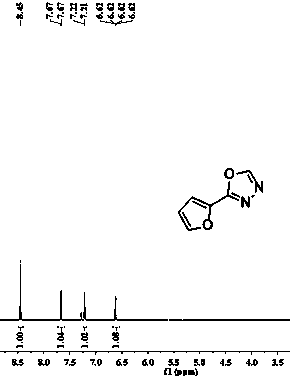

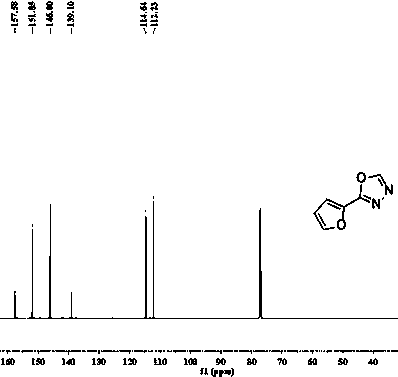

[0021] The structure of the product obtained in this embodiment is shown in figure 2 and image 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com