Preparation method of nickel niobium alloy

A nickel-niobium alloy and alloy technology, which is applied in the field of preparation of intermediate nickel-niobium alloys, can solve the problems of poor alloy uniformity and compactness, affecting alloy performance, reducing alloy purity, etc., achieving uniform and stable alloy, improving quality, and solving easy segregation problems. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

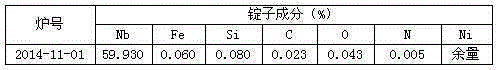

[0017] A method for preparing nickel-niobium alloy, which adopts intermediate frequency vacuum induction melting method, uses high-purity nickel and high-purity niobium as raw materials, and obtains the final product through intermediate frequency vacuum induction furnace melting; alloy composition by weight percentage, Nb: 59.0% ~ 61.0 %, Ni is the balance; a better alloy composition is: Nb: 59.5% to 60.5%, Ni is the balance.

[0018] The preparation method of a kind of nickel-niobium alloy of the present invention, described high-purity nickel and high-purity niobium raw material, its purity is greater than 99%; Its high-purity nickel and high-purity niobium raw material are dried, and drying temperature is 100 ℃~120 ℃, Drying time ≥ 4 hours. under vacuum conditions. According to conventional steps, heating and melting by electromagnetic induction, electromagnetic stirring to make the alloy composition uniform, and obtain the final product; the process parameters of smeltin...

Embodiment 2~5

[0036] Embodiment 2~5, operate according to the method of embodiment 1, see the table below for the difference with embodiment 1.

[0037] Table 2 Examples of nickel-niobium alloys

[0038]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com