Biomimetic calcium phosphate fiber composite bracket material and preparation method thereof

A stent material, fiber composite technology, applied in medical science, prosthesis, coating and other directions, can solve the problems of volatile, no three-dimensional stent structure, difficult to maintain regeneration space, etc., to improve strength and toughness, optimize the preparation process, The effect of high crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Mix 3.643g of triethyl phosphate, 2.76g of ethanol and 1.08g of deionized water to form a solution, and add nitric acid dropwise to adjust the pH of the solution to 2, and stir vigorously at 80°C for 48 hours to hydrolyze, according to the stoichiometry of Ca / P=1.0 Slowly add 2 mol / L calcium nitrate ethanol solution dropwise, stir the mixed solution for 2 hours, and then place it in the environment of -18°C for 7 days to age. The spinning solution was prepared according to the mass ratio of sol: water = 3: 1, and PVP (Mn = 1300,000) was added as a spinning aid, and the concentration of PVP was 4%wt. Electrospinning process parameters are as follows: ambient temperature 40°C, humidity below 30%, spinning solution flow rate 0.5mL / h, electrostatic voltage -18kV, distance between spinneret and fiber receiver 15cm, fiber receiving The surface temperature of the device was 80°C. After spinning for 10 hours, a white cotton-like hybrid fiber material was obtained. The obtaine...

Embodiment 2

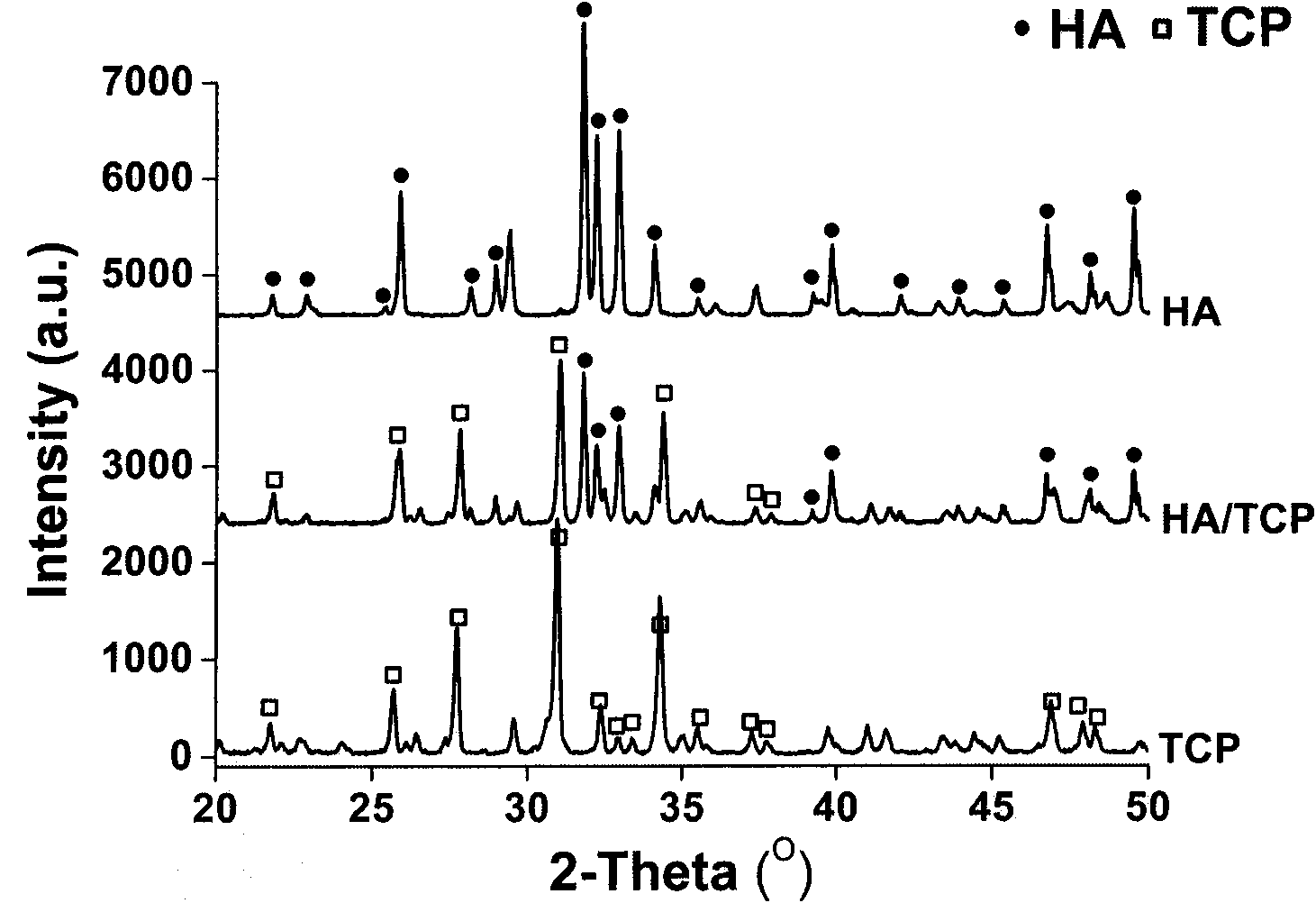

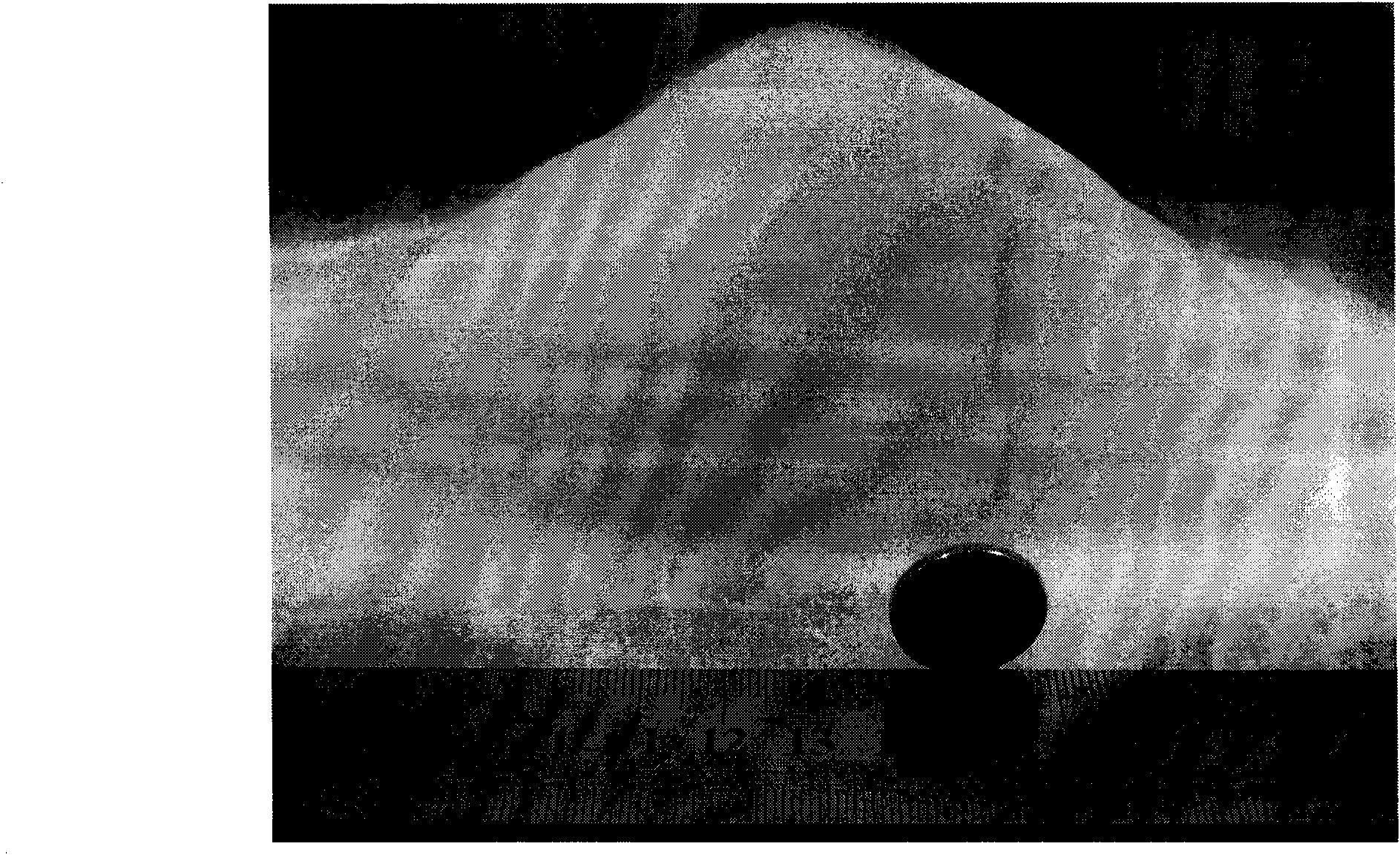

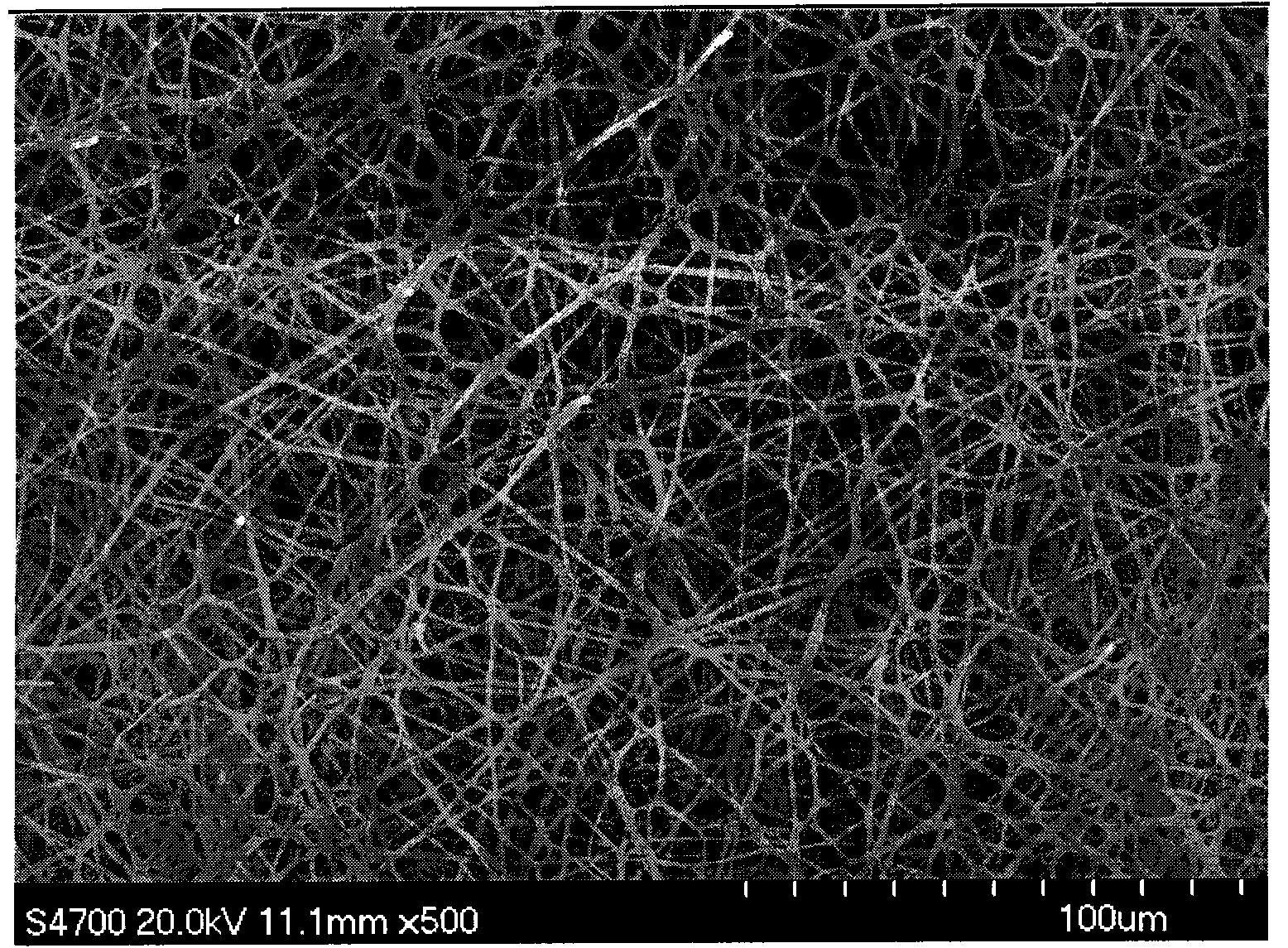

[0040] Mix 4.554g of triethyl phosphate, 3.45g of ethanol and 1.35g of deionized water to form a solution, stir vigorously at 50°C for 48 hours, and slowly add 3mol / L of calcium nitrate dropwise according to the stoichiometric ratio of Ca / P=1.5 Ethanol solution, continue to stir for 2 hours after the dropwise addition, and age at -18°C for 7 days. The spinning solution was prepared according to the mass ratio of sol: water = 5: 1, and PVA (Mn = 100,000) was added as a spinning aid, and the concentration of PVA was 8%wt. Electrospinning process parameters are as follows: ambient temperature 40°C, humidity below 30%, spinning solution flow rate 0.8mL / h, electrostatic voltage -22kV, distance between spinneret and fiber receiver 15cm, fiber receiving The surface temperature of the device was 80°C. After electrospinning for 10 hours, a white, cotton-like nanofiber material was obtained, as shown in figure 2 As shown, its microstructure is as image 3 The SEM photographs are sho...

Embodiment 3

[0042] Mix 2.802g of trimethyl phosphate, 1.84g of methanol and 0.72g of deionized water to form a solution, add ammonia water dropwise to adjust the pH of the solution to 9, stir vigorously at 50°C for 48 hours, and follow the stoichiometry of Ca / P=1.5 Slowly add 2 mol / L calcium nitrate ethanol solution dropwise, stir the mixed solution for 2 hours, and then place it in the environment of -18°C for 7 days to age. The spinning solution was prepared according to the mass ratio of sol:water=6:1, and high molecular weight PEO was added as a spinning aid, and the concentration of PEO was 10%wt. Electrospinning process parameters are as follows: ambient temperature 40°C, humidity below 30%, spinning solution flow rate 0.8mL / h, electrostatic voltage -10kV, distance between spinneret and fiber receiver 10cm, fiber receiving The surface temperature of the device was 80°C. After electrospinning for 10 h, white cotton-like nanofibers were obtained. The obtained hybrid fibers were trea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| coating thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com