Heat treatment method capable of effectively improving hardness of spheroidal graphite cast iron

A heat treatment method and technology of ductile iron, applied in the field of heat treatment technology or ductile iron structural material processing, to achieve the effects of ensuring process yield, reducing quenching cracks, and high process yield

Active Publication Date: 2019-06-07

CHANGCHUN UNIV OF TECH

View PDF3 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Use this method to process austempering ductile iron (ADI) for wear-resistant structural parts, and develop ductile iron with higher hardenability for this process, so that the matrix structure uses high-hardness martensite as the main structure, or increases the duplex Or the proportion of martensite in the multi-phase structure, so as to increase the hardness, and solve the problem that the brittleness of high-carbon martensite and residual structural stress will lead to the yield of heat treatment processing, so this method has better processability

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0034] The present invention will be further described in conjunction with an embodiment below.

[0035] 1. Selection and characteristics of experimental materials

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Login to View More

Abstract

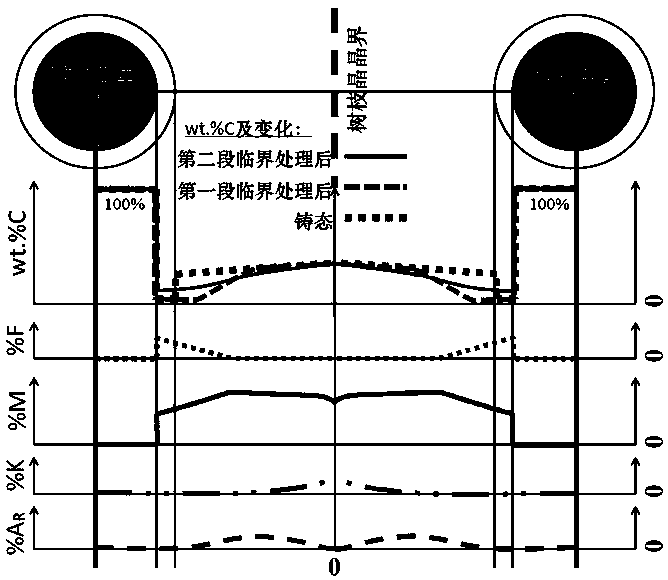

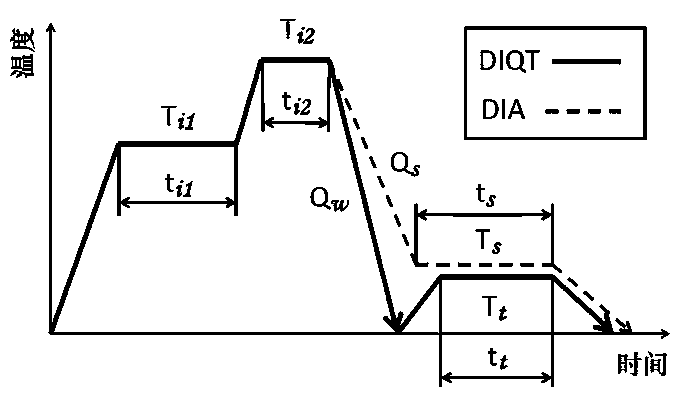

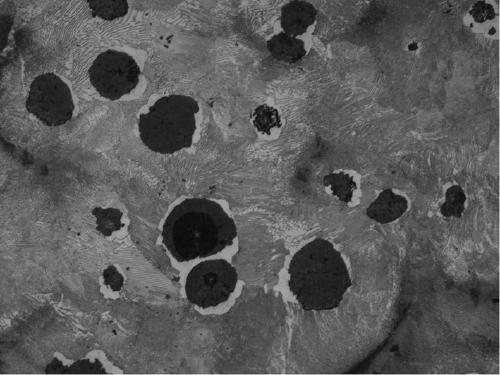

The invention belongs to the heat treatment technology or the technical field of spheroidal graphite cast iron structural material machining. The low dual critical temperature is adopted for carryingout austenitizing and quenching and low temperature tempering. Particularly, the first critical temperature is the eutectoid transition point A1, heat preservation is carried out under the first critical temperature or the close temperature, and a spheroidal graphite cast iron matrix is in transition to the hypoeutectoid component from the eutectoid component; the second critical temperature is the austenitizing temperature A3 point of hypoeutectoid steel, heat preservation is carried out under the austenitizing temperature A3 point or the close temperature, the matrix is mainly characterizedas hypoeutectoid steel insufficiency austenitizing, after quenching, after quenching, at the interface from the edge of spheroidal graphite to dendrite, the gradient control structure with the dendrite as the unit is obtained, and is a little non-converted ferritic toughening subcritical quenching structure and comprises eutectoid steel and nearly eutectoid steel fine martensite and not completelydissolved carbide, low tempering reduces quenching stress, and the matrix is toughened; and the advantages of being high in process yield, excellent in wear resistance, capable of reducing energy consumption, friendly to the environment, simple, easy to operate and the like are achieved.

Description

technical field [0001] The invention belongs to the technical field of heat treatment technology or the processing technology of nodular cast iron structural materials, and generally speaking is a heat treatment method for effectively improving the hardness of nodular cast iron. Background technique [0002] Ductile iron has been an important structural material for more than 70 years since it entered industrial production. [0003] Ductile iron with Aubeki body can be obtained by austempering, which has excellent performance, and its performance far exceeds the corresponding index of general steel, and has become an indispensable and important engineering material in various fields of national economy. [0004] The development of high-strength and wear-resistant ductile iron includes casting process and heat treatment process, especially the heat treatment process, including the development of carbide-containing ductile iron and bainite-martensite dual-phase or multi-phase ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C21D5/00

Inventor 王柏树陈华贾素秋韩英

Owner CHANGCHUN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com