Preparation method of pure single-phase ternary carbide Co3W3C

A ternary carbide, pure technology, applied in the field of hard alloy material preparation, can solve the problems of difficult control of composition and process, difficult control of preparation process, difficult control of relative content, etc., to reduce cold welding phenomenon and increase screening efficiency , reduce the effect of volatilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

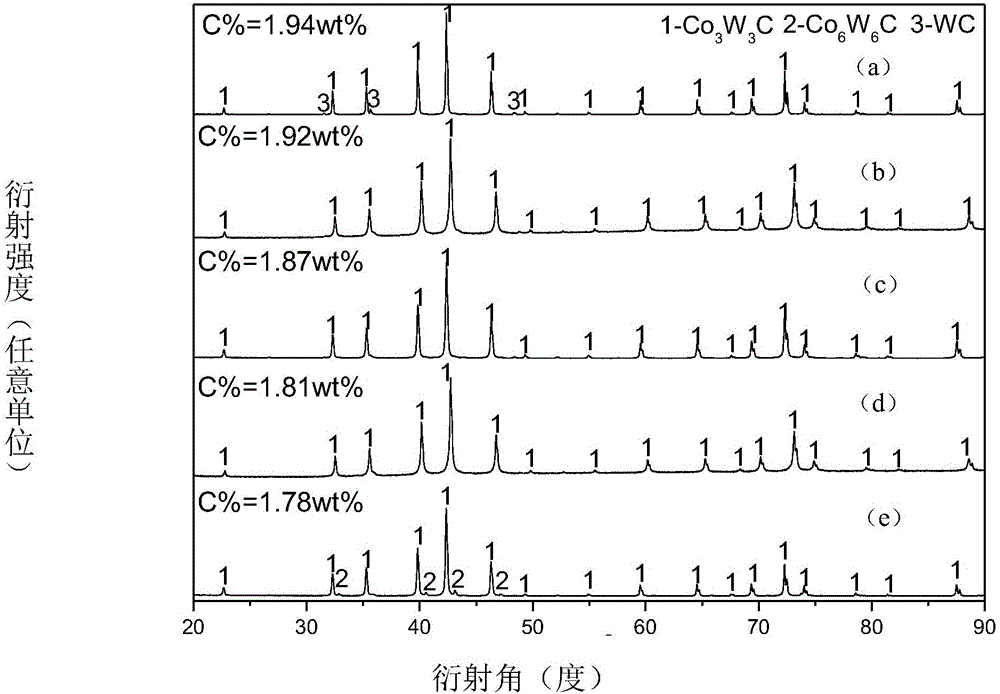

[0029] Take cobalt powder, 1.0um tungsten powder, and 0.6um carbon powder with an average particle size of 0.8um to prepare Co-W-C mixed powder, wherein the carbon content is 1.92wt%. Add the mixed powder, cemented carbide balls (4mm, 7mm, 9mm) of three different diameters, and absolute ethanol into the cemented carbide ball mill jar for intermittent ball milling. The weight ratio of cemented carbide balls to Co-W-C mixed powder is 3:1, the ball milling time is 24 hours, and the ball milling speed is 100r / min. Dry the mixed powder after ball milling, add absolute ethanol to cold press, the pressure is 6MPa, the compact is placed in a vacuum furnace for chemical reaction, the vacuum degree in the furnace is 0.03Pa, the heating rate is 6°C / min, and the reaction temperature is 1230°C , the holding time is 2 hours, and the pure single-phase ternary carbide Co can be obtained after rapid cooling 3 W 3 C powder green body, the powder green body is subjected to intermittent ball mi...

Embodiment 2

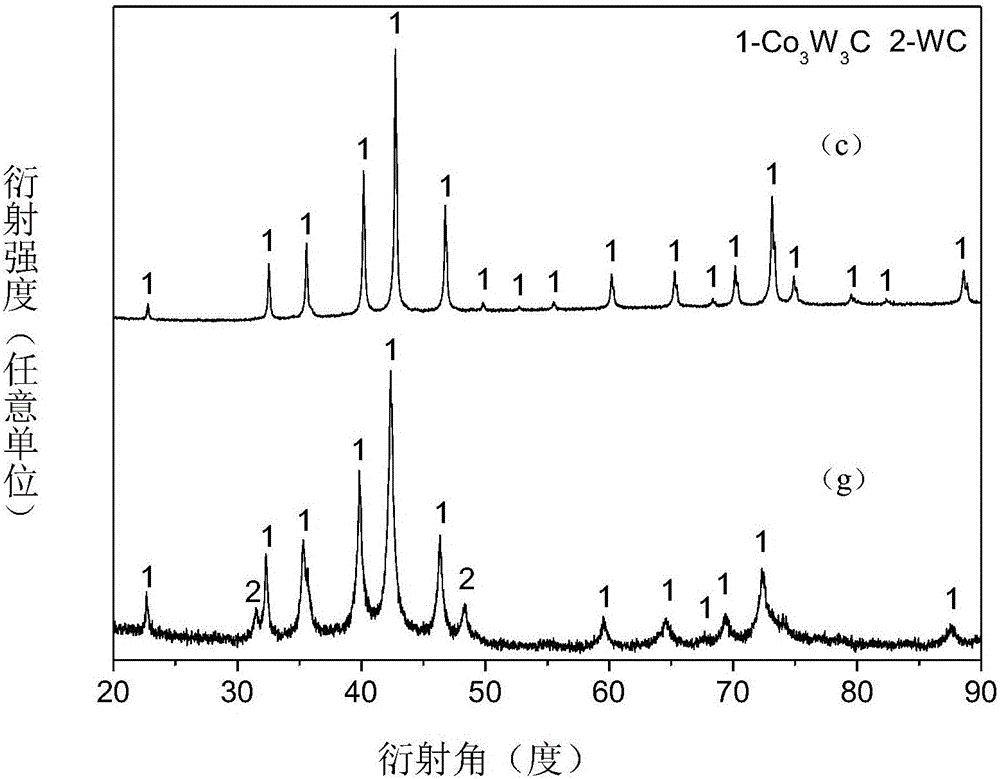

[0031] Take cobalt powder, 0.6um tungsten powder, and 0.5um carbon powder with an average particle size of 0.8um to prepare Co-W-C mixed powder, wherein the carbon content is 1.87wt%. Add the mixed powder, cemented carbide balls (4mm, 8mm, 10mm) of three different diameters, and absolute ethanol into the cemented carbide ball mill jar for intermittent ball milling. The weight ratio of cemented carbide balls to Co-W-C mixed powder is 2:1, the ball milling time is 30 hours, and the ball milling speed is 120r / min. Dry the mixed powder after ball milling, add absolute ethanol to cold press, the pressure is 5MPa, the compact is placed in a vacuum furnace for chemical reaction, the vacuum degree in the furnace is 0.04Pa, the heating rate is 5°C / min, and the reaction temperature is 1270°C , the holding time is 1 hour, and the pure single-phase ternary carbide Co can be obtained after rapid cooling 3 W 3 C powder green body, the powder green body is subjected to intermittent ball mi...

Embodiment 3

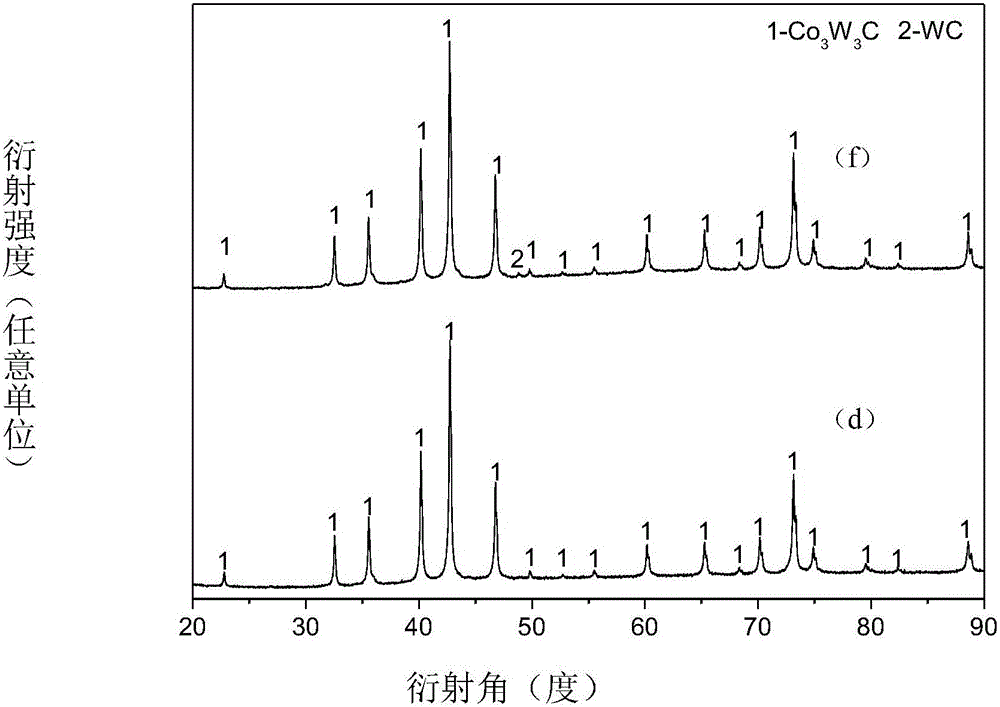

[0033] Take cobalt powder, 0.8um tungsten powder, and 0.6um carbon powder with an average particle size of 1.0um to prepare Co-W-C mixed powder, wherein the carbon content is 1.81wt%. Add the mixed powder, cemented carbide balls (3mm, 8mm, 10mm) of three different diameters, and absolute ethanol into the cemented carbide ball mill jar for intermittent ball milling. The weight ratio of cemented carbide balls to Co-W-C mixed powder is 3:1, the ball milling time is 30 hours, and the ball milling speed is 80r / min. Dry the mixed powder after ball milling, add absolute ethanol and cold press, the pressure is 6MPa, the compact is placed in a vacuum furnace for chemical reaction, the vacuum degree in the furnace is 0.04Pa, the heating rate is 4°C / min, and the reaction temperature is 1300°C , the holding time is 2 hours, and the pure single-phase ternary carbide Co can be obtained after rapid cooling 3 W 3 C powder green body, the powder green body is subjected to intermittent ball m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com