Bismuth ferrite base film layer stacked structure capacitor and preparation method thereof

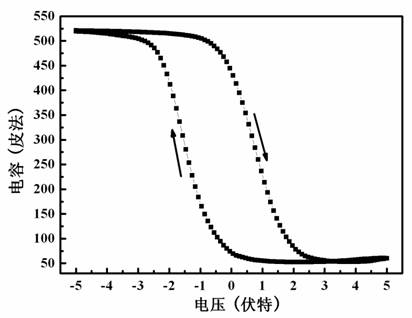

A stacked structure, capacitor technology, applied in the direction of electrical solid-state devices, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of large leakage current, high interface trap density, and inconformity with the working voltage of silicon-based integrated circuits, etc., to achieve good crystal Lattice matching relationship, large dielectric constant, good insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

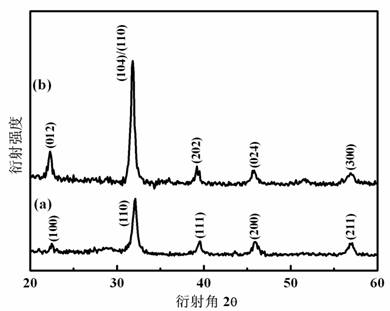

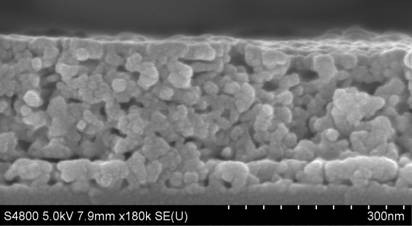

[0054] Preparation of Au / Bi 0.9 La 0.1 FeO 3 / Ba 0.6 Sr 0.4 Ti 0.97 mn 0.03 o 3 / Si capacitors, the steps are as follows:

[0055] (1) Ba 0.6 Sr 0.4 Ti 0.97 mn 0.03 o 3 Film preparation

[0056] Weigh 0.3096g Ba(CH 3 COO) 2 , 0.0163g Mn(CH 3 COO) 3 2H 2 O, 0.1744g Sr(CH 3 COO) 2 0.5H 2 Dissolve O in 19.41ml of glacial acetic acid, stir magnetically at 60°C, and stop heating when it is completely dissolved; when the solution is cooled to room temperature, add acetylacetone and tetratitanate at a volume ratio of 1:1 to the above solution For isopropyl ester, first add 0.59ml acetylacetone, then add 0.59ml tetraisopropyl titanate dropwise, and continue to stir until the distribution is even; finally add 19.41ml ethylene glycol methyl ether, and continue stirring at room temperature for 6 hours. Filter the solution into the drop bottle with a filter head with a pore size of 0.2 μm to obtain a uniform and transparent 0.05mol / L 40ml Ba 0.6 Sr 0.4 Ti 0.97 mn ...

Embodiment 2

[0063] Preparation of Au / Bi 0.95 Ce 0.05 FeO 3 / Ba 0.6 Sr 0.4 Ti 0.955 mn 0.045 o 3 / Si capacitors, the steps are as follows:

[0064] (1) Ba 0.6 Sr 0.4 Ti 0.955 mn 0.045 o 3 Film preparation

[0065] Weigh 0.2477g Ba(CH 3 COO) 2 , 0.0195g Mn(CH 3 COO) 3 2H 2 O, 0.1395g Sr(CH 3 COO) 2 0.5H 2 Dissolve O in 26.04ml of glacial acetic acid, stir magnetically at 60°C, and stop heating when it is completely dissolved; when the solution is cooled to room temperature, add acetylacetone and tetratitanate at a volume ratio of 1:1 to the above solution For isopropyl ester, first add 0.47ml acetylacetone, then add 0.47ml tetraisopropyl titanate dropwise, and continue to stir until the distribution is uniform; finally add 13.02ml ethylene glycol methyl ether, and continue stirring at room temperature for 6 hours. Filter the solution into the drop bottle with a filter head with a pore size of 0.2 μm to obtain a uniform and transparent 0.04mol / L 40ml Ba 0.6 Sr 0.4 Ti ...

Embodiment 3

[0071] Preparation of Au / Bi 0.85 SM 0.15 FeO 3 / Ba 0.6 Sr 0.4 Ti 0.98 mn 0.02 o 3 / Si capacitors, the steps are as follows:

[0072] (1) Ba 0.6 Sr 0.4 Ti 0.98 mn 0.02 o 3 Film preparation

[0073] Weigh 0.1239g Ba(CH 3 COO) 2 , 0.0040g Mn(CH 3 COO) 3 2H 2 O, 0.0698g Sr(CH 3 COO) 2 0.5H 2 Dissolve O in 23.71ml of glacial acetic acid, stir magnetically at 60°C, and stop heating when it is completely dissolved; when the solution is cooled to room temperature, add acetylacetone and tetratitanate at a volume ratio of 1:1 to the above solution. For isopropyl ester, first add 0.24ml acetylacetone, then add 0.24ml tetraisopropyl titanate dropwise, and continue to stir until the distribution is uniform; finally add 15.81ml ethylene glycol methyl ether, and continue stirring at room temperature for 6 hours. Filter the solution into the drop bottle with a filter head with a pore size of 0.2 μm to obtain a uniform and transparent 0.02mol / L 40ml Ba 0.6 Sr 0.4 Ti 0.9...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com