Balanced macroelement clear liquid fertilizer

A high-element, balanced technology, used in liquid fertilizers, urea compound fertilizers, nitrogen fertilizers, etc., can solve problems such as high production costs, unstable long-term storage, flatulence, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

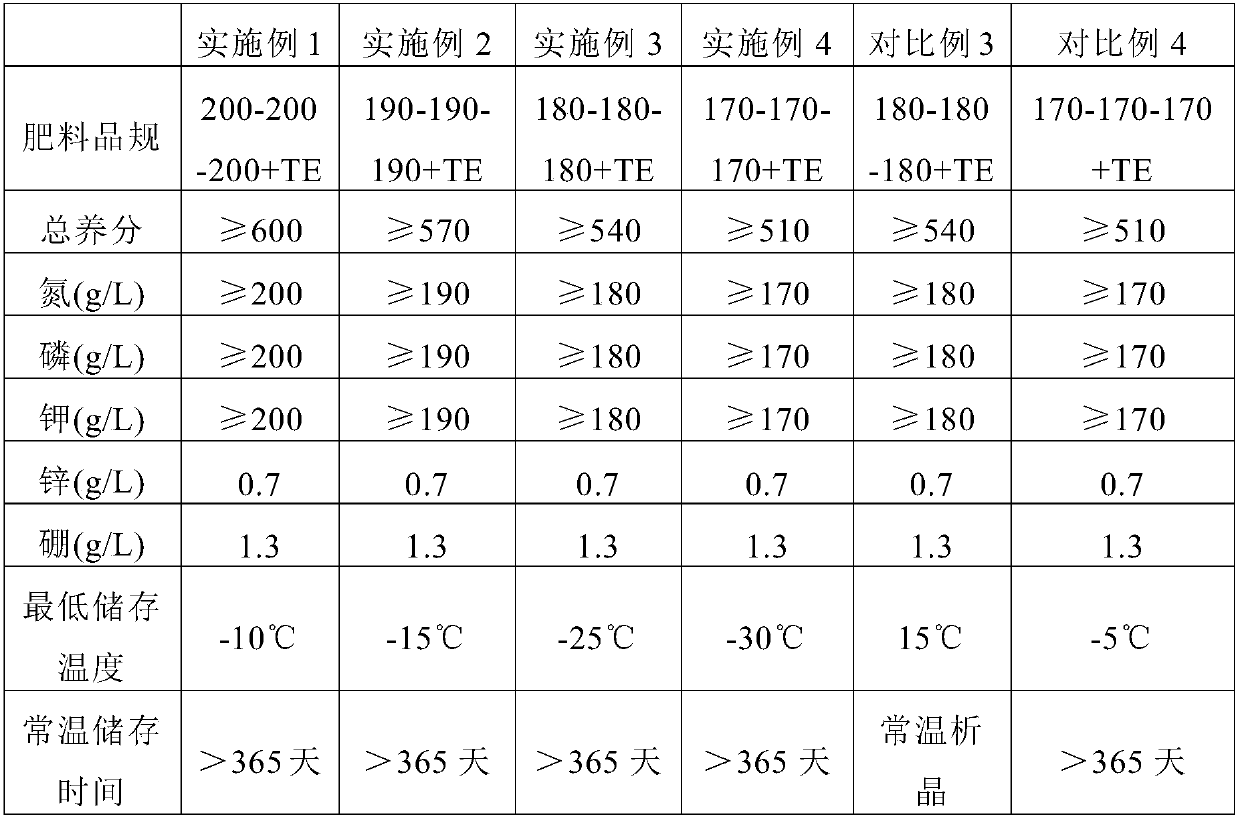

Embodiment 1

[0047] The balanced type macroelement clear liquid fertilizer containing urea-formaldehyde nitrogen solution, by weight: 45.3 parts of urea-formaldehyde nitrogen solution with nitrogen content of 32%, 23.6 parts of 85% thermal phosphoric acid, 18.1 parts of 95% industrial grade potassium hydroxide, four 0.45 parts of sodium octaborate in water, 0.35 parts of EDTA-Zn, appropriate amount of stabilizer, make up to 100 parts of water, and prepare 200-200-200+TE clear liquid fertilizer.

[0048] Preparation steps of clear liquid fertilizer:

[0049] 1) Weigh 12 parts of water, put it into the reaction kettle, put 18.1 parts of 95% industrial grade potassium hydroxide in batches under stirring condition, and control the solution temperature to ≤60°C;

[0050] 2) Continue to drop 45.3 parts of 32% urea-formaldehyde nitrogen solution into the kettle, and stir evenly;

[0051] 3) Continue to put 23.6 parts of 85% thermal phosphoric acid into the kettle, add in batches, and control the...

Embodiment 2

[0056]The balanced macroelement clear liquid fertilizer containing urea-formaldehyde nitrogen solution, by weight parts: nitrogen content is 46.3 parts of urea-formaldehyde nitrogen solution of 30%, 16.2 parts of 99% industrial grade phosphorous acid, 17.4 parts of 95% industrial grade potassium hydroxide, 0.45 parts of sodium octaborate tetrahydrate, 0.35 parts of EDTA-Zn, appropriate amount of stabilizer, water to make up to 100 parts, and prepare 190-190-190+TE clear liquid fertilizer.

[0057] Preparation steps of clear liquid fertilizer:

[0058] 1) Weigh 18 parts of water, put it into the reaction kettle, put 17.4 parts of 95% industrial grade potassium hydroxide in batches under stirring condition, and control the solution temperature to ≤60°C;

[0059] 2) Continue to drop 46.3 parts of 30% urea-formaldehyde nitrogen solution into the kettle, and stir evenly;

[0060] 3) Continue to put 16.2 parts of 99% industrial-grade phosphorous acid into the kettle, add in batches...

Embodiment 3

[0065] Balanced macroelement clear liquid fertilizer containing urea-formaldehyde nitrogen solution, in parts by weight: 30.7 parts of urea-formaldehyde nitrogen solution with a nitrogen content of 28%, 10 parts of urea, 25.4 parts of potassium dihydrogen phosphate, 5.7 parts of 95% industrial grade potassium hydroxide 10 parts of formic acid, 0.5 parts of γ-polyglutamic acid, 0.45 parts of sodium octaborate tetrahydrate, 0.35 parts of EDTA-Zn, appropriate amount of stabilizer, and make up to 100 parts of water to prepare 180-180-180+TE clear liquid fertilizer.

[0066] Preparation steps of clear liquid fertilizer:

[0067] 1) Weigh 17 parts of water, put it into the reaction kettle, put 5.7 parts of 95% industrial grade potassium hydroxide in batches under stirring condition, and control the solution temperature to ≤60°C;

[0068] 2) Continue to put 30.7 parts of 28% urea-formaldehyde nitrogen solution and 10 parts of urea into the kettle, and stir until it dissolves evenly; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallization temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com