Process of preparing mesoporous molecular sieve with ionic liquid as template agent

A technology of mesoporous molecular sieve and ionic liquid, which is applied in coke cooling, petroleum industry, coke oven, etc., can solve the problem of high crystallization temperature, and achieve the effect of low crystallization temperature and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The first step template preparation

[0020] Mix N-methylimidazole and hexadecane bromide in a molar ratio of 1:1, react under nitrogen protection at 110°C for 48 hours, cool to room temperature, and obtain a light yellow waxy solid, which is recrystallized with chloroform to obtain a white powder, ionic liquid 1-hexadecyl-3-methylimidazole bromide, namely [C 16 mim]Br;

[0021] Preparation of the second step reaction mixture

[0022] Press Na 2 SiO 3 9H 2 Si in O: [C 16 mim] Br: Al 2 (SO 4 ) 3 Al:H in 2 SO 4 :H 2 The molar ratio of O=1: 0.5: 0.02: 0.8: 124 configure raw materials, prepare reaction mixture (Si / Al=50), under normal temperature, 7.1gNa 2 SiO 3 9H 2 O was dissolved in 12.5 g of deionized water, and 2.67 g of 3.27%wt Al was first added dropwise to the solution 2 (SO 4 ) 3 Aqueous solution, and then add dropwise to the solution containing 4.8g [C 16 mim]Br in water, with H 2 SO 4 Adjust the pH value of the solution to 9.5 to prepare a rea...

Embodiment 2

[0027] Operation process is except following difference, all the other are with embodiment 1:

[0028] Preparation of the second step reaction mixture

[0029] Press Na 2 SiO 3 9H 2 Si in O: [C 16 mim] Br: Al 2 (SO 4 ) 3 Al:H in 2 SO 4 :H 2 The molar ratio of O=1:0.5:0.01:0.8:93 Prepare the raw materials and prepare the reaction mixture (Si / Al=100).

[0030] The third step hydrothermal crystallization

[0031] The raw powder was put into a muffle furnace and calcined at 520°C for 5 hours to obtain Al-MCM-41 mesoporous molecular sieve.

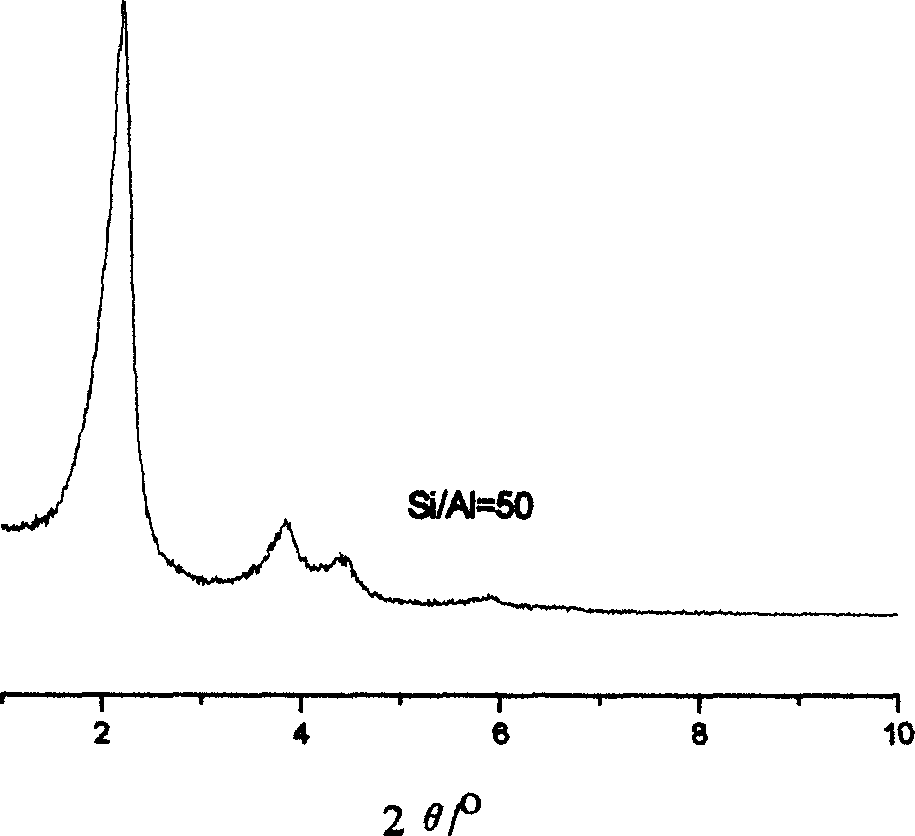

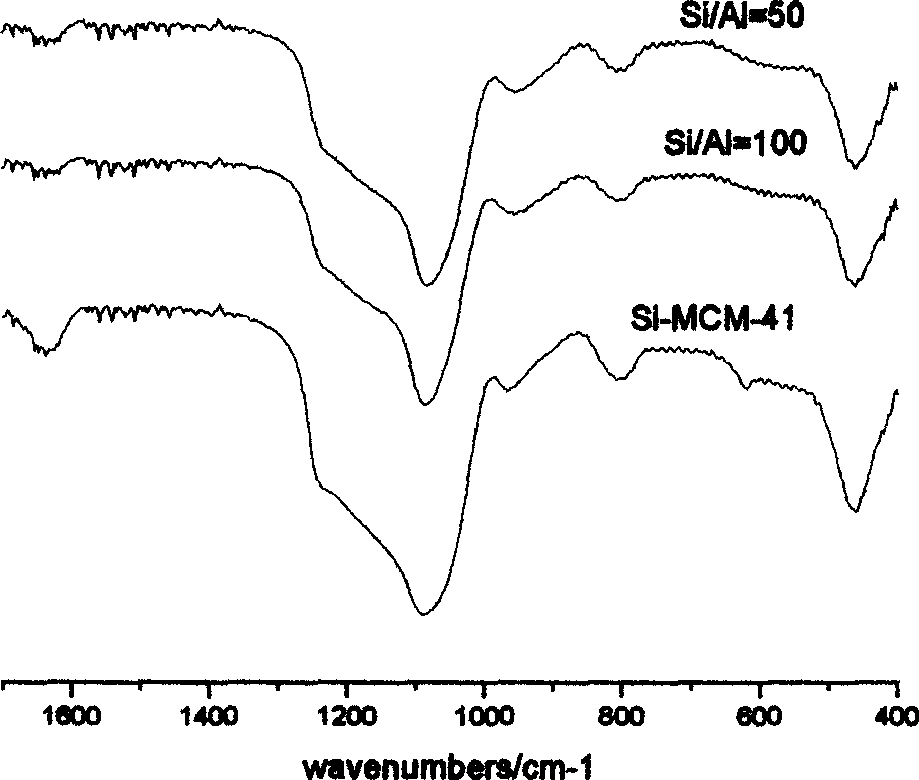

[0032] The XRD spectrum and IR spectrum of the obtained Al-MCM-41 mesoporous molecular sieve are respectively compared with figure 1 and figure 2 similar.

Embodiment 3

[0034] Operation process is except following difference, all the other are with embodiment 1:

[0035] Preparation of the second step reaction mixture

[0036] Press Na 2 SiO 3 9H 2 Si in O: [C 16 mim] Br: Al 2 (SO 4 ) 3 Al:H in 2 SO 4 :H 2 The molar ratio of O=1:0.5:0.05:0.8:106 Prepare the raw materials and prepare the reaction mixture (Si / Al=20).

[0037] The third step hydrothermal crystallization

[0038] The raw powder was put into a muffle furnace and calcined at 580°C for 5h to obtain Al-MCM-41 mesoporous molecular sieve.

[0039] The XRD spectrum and IR spectrum of the obtained Al-MCM-41 mesoporous molecular sieve are respectively compared with figure 1 and figure 2 similar.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com