Process for preparing anatase type TiO2 sol

An anatase type, titanium dioxide technology, applied in the direction of titanium dioxide, chemical instruments and methods, titanium oxide/hydroxide, etc., can solve the problems of no photocatalytic activity, harsh process conditions, and excessive sol time, and achieve the process Simple conditions, good bonding, avoiding the effect of high temperature heat treatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

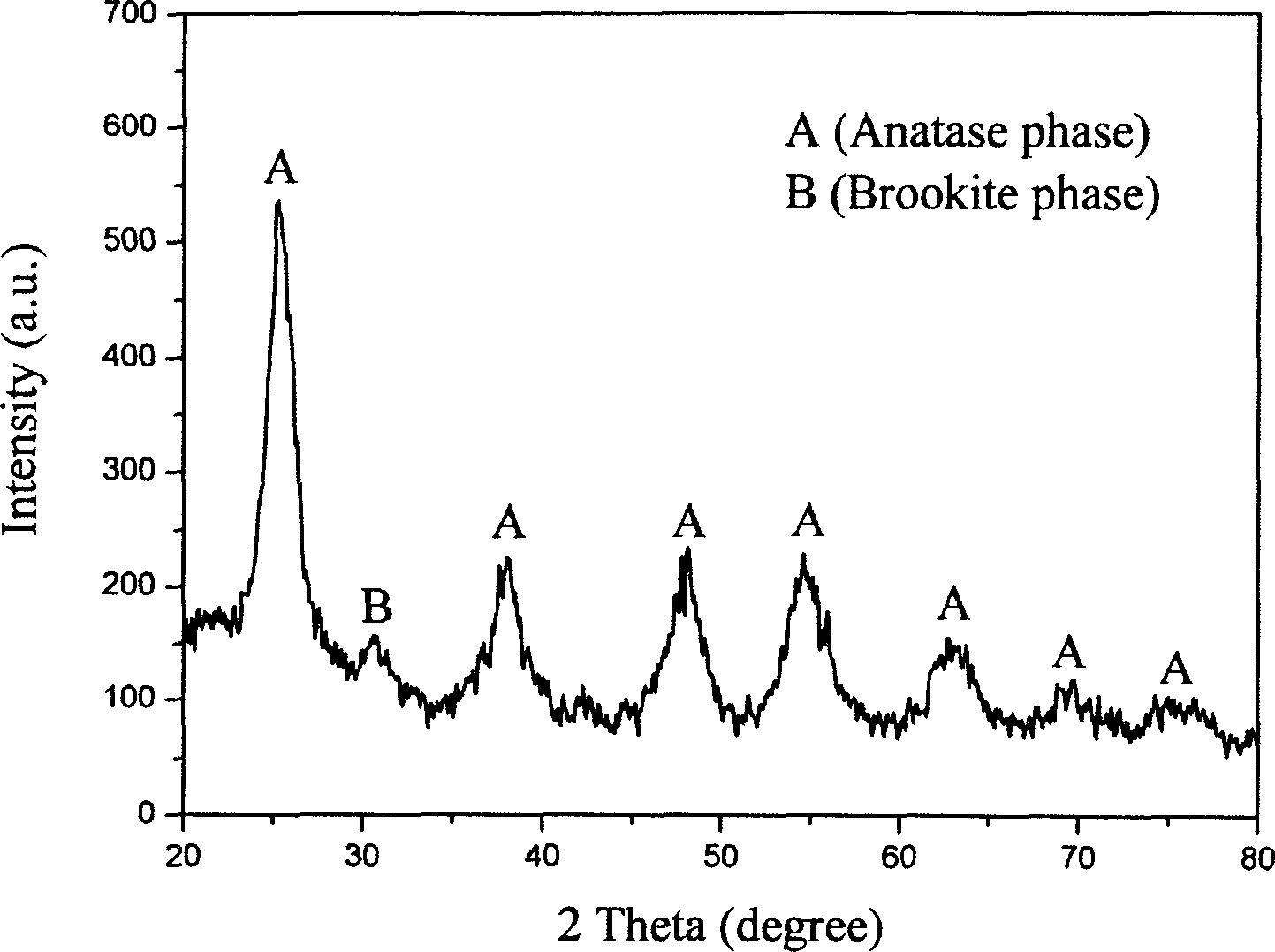

Embodiment 1

[0019] A kind of anatase type TiO for preparing photocatalytic material 2 The preparation method of the sol is that the molar ratio of the titanium compound and the alcohol is 1: 1.42~12, and the titanium compound and the alcohol are configured into an alcohol solution of the titanium compound. In this embodiment, the molar ratio of the titanium compound and the alcohol can be Select 1:1.42, 1:12, 1:4, 1:6 or 1:8, under stirring, add the alcohol solution of titanium compound dropwise to the aqueous acid solution of pH=1.0-4.0 for hydrolysis and the titanium compound and acid The molar ratio of water in the aqueous solution of the acid is 1:76 to 151. In this embodiment, the molar ratio of the titanium compound to the water in the aqueous acid solution can be 1:76, 1:151, 1:92 or 1:136 , after refluxing at 65-85°C for 6-48 hours, the resulting sol was evaporated at 50-55°C to remove alcohols to obtain anatase TiO 2 Sol. The above-mentioned titanium compounds can be organic ti...

Embodiment 2

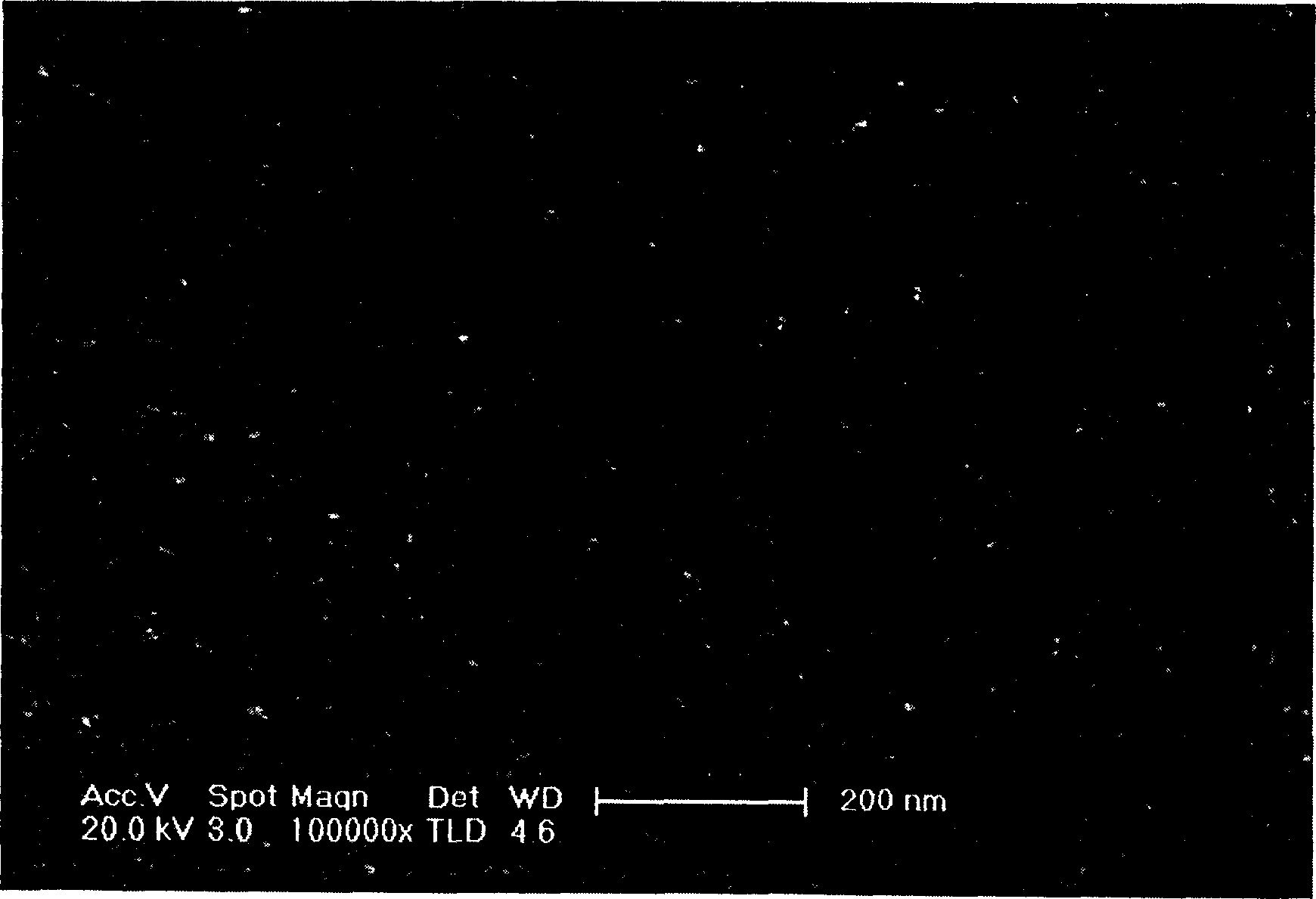

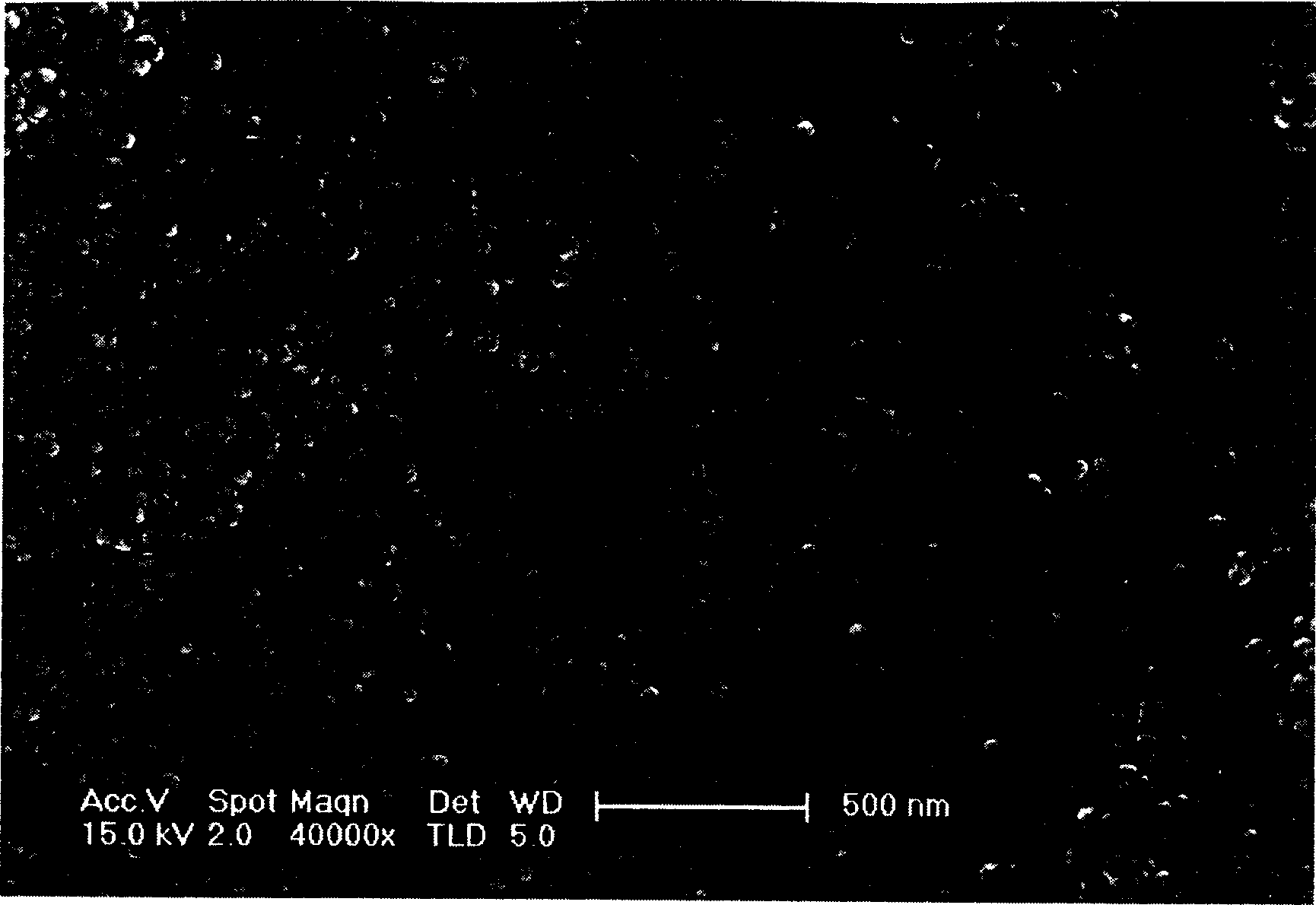

[0021] This embodiment is an example of a specific application. Under vigorous stirring, the isopropanol solution of tetra-n-butyl titanate was added dropwise to the aqueous solution at a constant speed, and the pH value of the aqueous solution was adjusted to 2.5 with concentrated nitric acid. Water, isopropanol and tetra-n-butyl titanate The molar ratios are 76 and 1.42 respectively, and the reaction solution is stirred and refluxed for 6, 24 or 48 hours at a constant temperature of 68 ° C, 75 ° C or 85 ° C, and then the reaction solution is heated at 50 ° C, 52 ° C or 55 ° C under reduced pressure with a rotary evaporator. The alcohols in the solution are removed under the conditions, and finally pure TiO is obtained 2 Sol.

[0022] Coating a layer of SiO on the surface of the base material 2 film, using SiO 2 film to ensure the stability of the substrate material while enhancing the TiO 2 Adhesion of the film to the substrate material. The plexiglass and silicone rubb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com