Method for preparing SHS ceramic liner metal tube from iron-based wastes

A metal pipe and ceramic lining technology, applied in the field of resource recycling and surface coating, to achieve the effect of wide source of raw materials, reduce raw material costs, and prevent deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

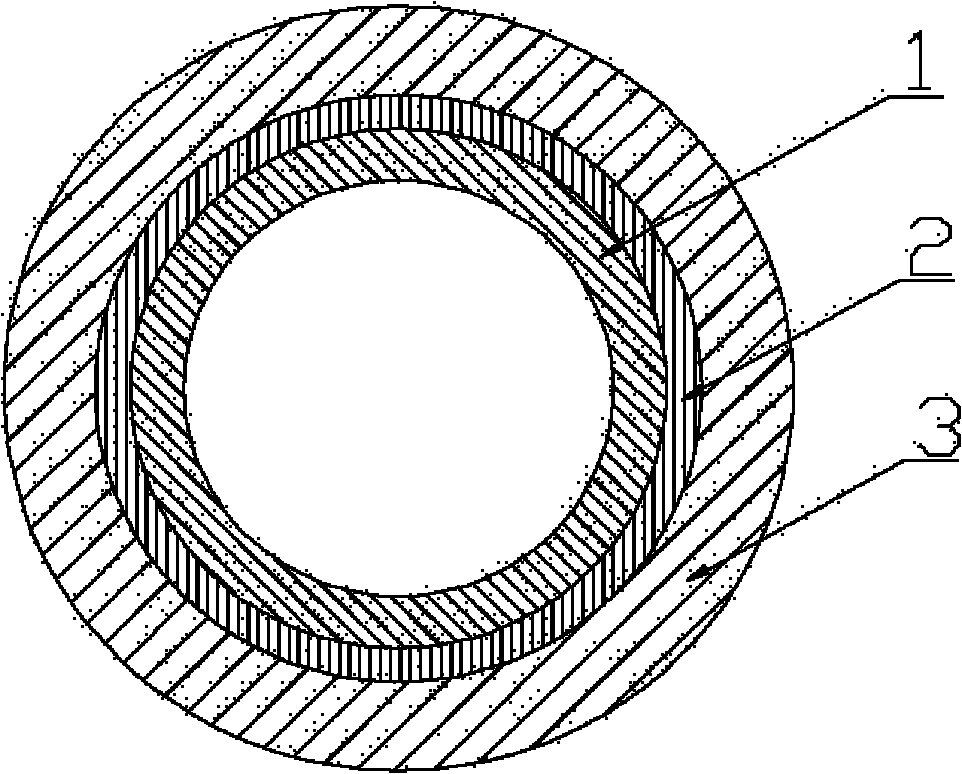

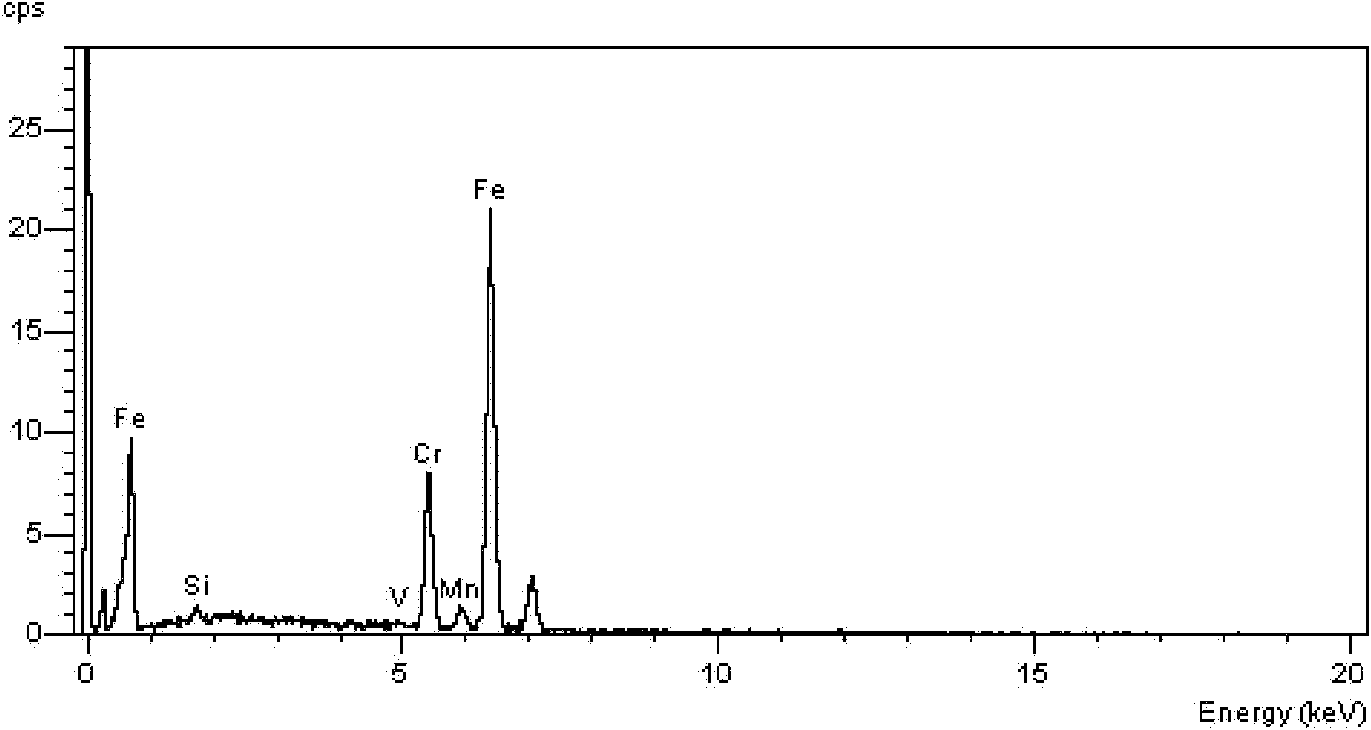

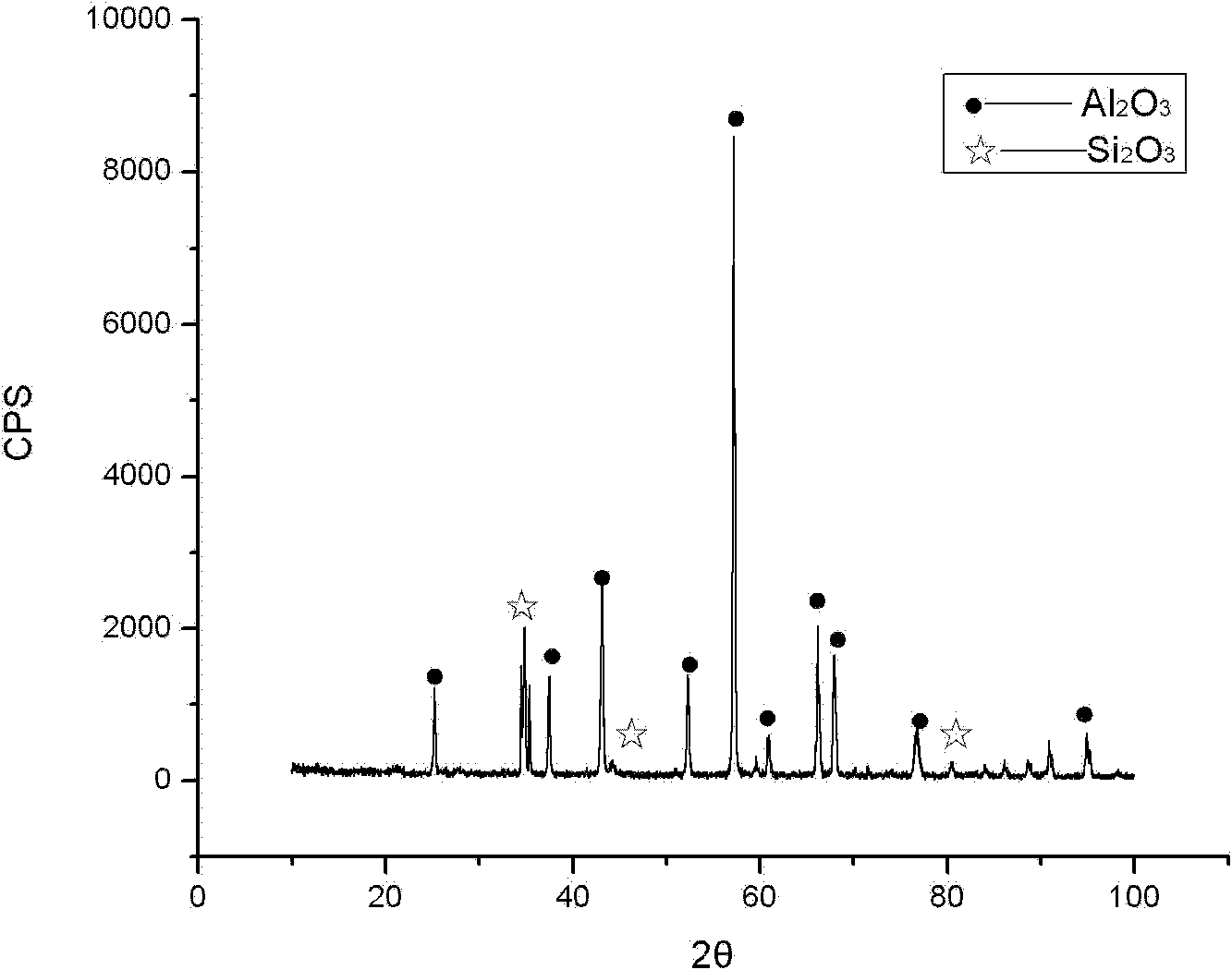

[0035] Will contain Cr, Ni, V, Mn metal elements (see figure 2 ), Al 2 o 3 and SiO 2 of iron-based scrap (see image 3 ) was baked at 200°C to remove water vapor and impurities, and sieved to obtain -80 mesh powder. It is evenly mixed with reducing agent Al powder, and its mass ratio is Al powder: iron-based waste material is 1:10. The mixture is evenly loaded into the steel pipe and fixed on the pipe making machine. Start the centrifuge, and when the rotating speed reaches 800 rpm, ignite the mixture with a tungsten wire to sinter by SHS centrifugal reaction. Under the action of centrifugal force, a steel pipe with a "sandwich" structure is formed, from the inside to the outside, in order of ceramic layer 1, ferroalloy layer 2 and steel pipe matrix layer 3. The crushing strength of the steel pipe is 326MPa, and the hardness is 1280kgf / mm 2 . Steel pipe linings were at 20% H 2 SO 4 , 20% HCl and aqua regia accelerated corrosion, the weight loss is 0.08g / m3 2 d, 0.0...

Embodiment 2

[0037] It will contain metal elements such as Cr, Ni, V, Mn (see figure 2 ), Al 2 o 3 and SiO 2 of iron-based scrap (see image 3 ) was baked at 300°C to remove water vapor and impurities, and sieved to obtain -120 mesh powder. It is evenly mixed with reducing agent Al powder, and its mass ratio is Al powder: iron-based waste material is 1:5. The mixture is evenly loaded into the steel pipe and fixed on the pipe making machine. Start the centrifuge, and when the rotating speed reaches 1200 rpm, ignite the mixture with a tungsten wire to sinter by SHS centrifugal reaction. Under the action of centrifugal force, a steel pipe with a "sandwich" structure is formed, from the inside to the outside, in order of ceramic layer 1, ferroalloy layer 2 and steel pipe matrix layer 3. The crushing strength of the steel pipe is 315MPa, and the hardness is 1380kgf / mm 2 . Steel pipe linings were at 20% H 2 SO 4 , 20% HCl and aqua regia accelerated corrosion, the weight loss is 0.06g / ...

Embodiment 3

[0039] It will contain metal elements such as Cr, Ni, V, Mn (see figure 2 ), Al 2 o 3 and SiO 2 of iron-based scrap (see image 3 ) was baked at 400°C to remove water vapor and impurities, and sieved to obtain -180 mesh powder. It is evenly mixed with reducing agent Al powder, and its mass ratio is Al powder: iron-based waste material is 1:1. The mixture is evenly loaded into the steel pipe and fixed on the pipe making machine. Start the centrifuge, and when the rotating speed reaches 1400 rpm, ignite the mixture with a tungsten wire to sinter by SHS centrifugal reaction. Under the action of centrifugal force, a steel pipe with a "sandwich" structure is formed, from the inside to the outside, in order of ceramic layer 1, ferroalloy layer 2 and steel pipe matrix layer 3. The crushing strength of the steel pipe is 308MPa, and the hardness is 1420kgf / mm 2 . Steel pipe linings were at 20% H 2 SO 4 , 20% HCl and aqua regia accelerated corrosion, the weight loss is 0.05g / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| crushing strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com