Preparation method of electronic grade manganous nitrate for tantalum capacitor

A technology of tantalum capacitors and manganese nitrate, which is applied in the field of preparation of electronic grade manganese nitrate for tantalum capacitors, can solve the problems of uneven manganese dioxide layer, high chemical impurity content, different particle sizes, etc. The effect of good crystal structure and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

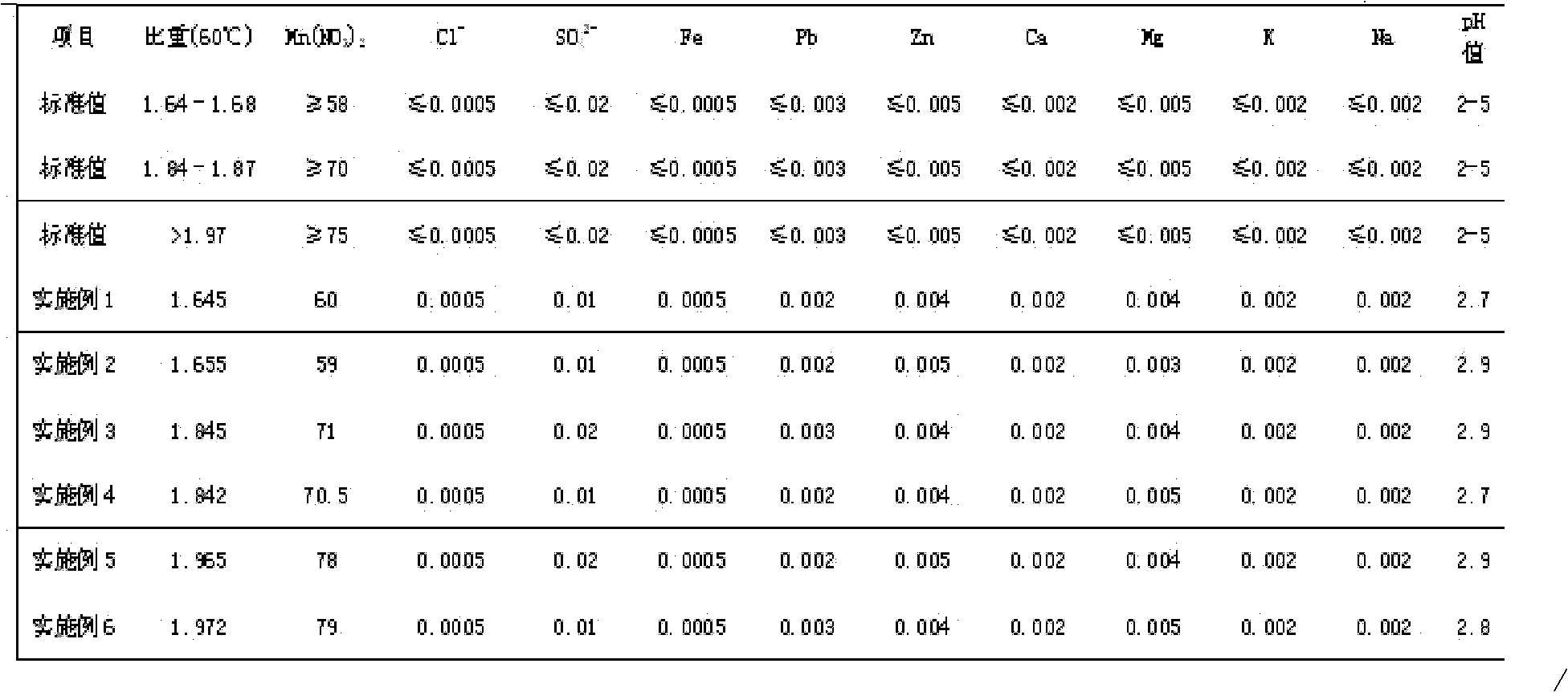

Embodiment 1

[0029] Add 950L of pure water, turn on the stirring paddle and ventilate, slowly add 180L of analytical pure nitric acid, stir evenly, and obtain dilute nitric acid solution.

[0030] The average particle size after crushing (crushing electrolytic manganese metal flakes using a mill and sieve machine), washing (crushing electrolytic manganese powder, using pure water, standing for 10 minutes, and pouring out the supernatant obtained after settling) is 85 mesh. Add a batch of metal manganese (60kg) into the dissolving tank filled with dilute nitric acid, stir while adding, and dissolve completely after 0.5 hours. The pH value of the solution is 6.9, and let it stand for 10 minutes; The tank is subjected to coarse filtration, and the filtrate is filtered into the storage tank, and then dilute nitric acid is used to adjust the acidity of the filtrate, and the pH value is 2.0; 1100L clear liquid is poured into a vacuum concentration pot with a vacuum degree of 0.03Mpa, heated and e...

Embodiment 2

[0032] Add 970L of pure water, turn on the stirring paddle and ventilate, slowly add 190L of analytical pure nitric acid, stir evenly, and obtain dilute nitric acid solution.

[0033] The average particle size after crushing (using a sieving machine to crush the electrolytic manganese metal flakes), washing (the crushed electrolytic manganese powder is washed with pure water, placed for 40 minutes, and the supernatant obtained after settling) is 85 mesh. Add batches of metal manganese (62kg) into the dissolving tank filled with dilute nitric acid, stir while adding, and dissolve completely after 0.5 hours. The pH value of the solution is 7.0, and leave it for 22 minutes; The filter tank is subjected to coarse filtration, and the filtrate is filtered into the storage tank, and then the filtrate is acidified with dilute nitric acid, and the pH value is 3.2; 1120L clear liquid is poured into a vacuum concentration pot with a vacuum degree of 0.04Mpa, heated and evaporated for 24 h...

Embodiment 3

[0035] Add 1000L of pure water, turn on the stirring paddle and ventilate, slowly add 190L of analytical pure nitric acid, stir evenly, and obtain dilute nitric acid solution.

[0036] The average particle size after crushing (crushing electrolytic manganese metal flakes using a mill and sieve machine), washing (crushing electrolytic manganese powder, using pure water, standing for 30 minutes, and pouring out the supernatant obtained after settling) is 90 mesh. Add batches of manganese metal (75kg) into the dissolving tank filled with dilute nitric acid, stir while adding, and dissolve completely after 0.5 hours. The pH value of the solution is 6.7, and let it stand for 25 minutes; Coarsely filter the filter tank, filter the filtrate into the storage tank, and then use dilute nitric acid to adjust the acidity of the filtrate, the pH value is 3.4; put 1200L clear liquid into a vacuum concentration pot with a vacuum degree of 0.05Mpa, heat and evaporate for 24 hours, and the evap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com