Method for preparing water-based Fe3O4 magnetic fluid

A magnetic fluid, water-based technology, used in magnetic liquids, manganese nitrate, etc., can solve the problems of poor biological compatibility, magnetic fluid containing organic substances, etc., and achieve the effects of good stability, simple operation and good water solubility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0007] Specific implementation mode one: water-based Fe in this implementation mode 3 o 4 The preparation method of magnetic fluid is as follows: one, FeCl 3 with FeCl 2 Dissolve in deionized water at a molar ratio of 2:1, and then use 37% HCl to adjust the pH value to 1 to 2; 2. In an oil bath at 120 to 180°C, under the protection of inert gas nitrogen or argon, Add NaOH solution with a concentration of 8-15mol / L dropwise to the solution in step 1 within 20-40 minutes, wherein NaOH and FeCl 3 The mol ratio is 3~10: 1, then with 1200~1800r / min speed insulation stirring 0.5~2.5 hours, naturally cool to room temperature; Ionized water, ultrasonically disperse until all the black solids are dissolved, settle the black solids with a permanent magnet, and pour off the upper liquid when the upper liquid is clear; 4. Repeat step 3 until the solution does not contain chloride ions and is neutral; 5. Ultrasonic disperse the solution treated in step 4 in deionized water of 1 to 3 ti...

specific Embodiment approach 2

[0010] Specific embodiment two: the difference between this embodiment and specific embodiment one is that NaOH and FeCl in step two 3 The molar ratio is 9:1, and the others are the same as in Embodiment 1.

specific Embodiment approach 3

[0011] Specific embodiment three: the difference between this embodiment and specific embodiment one is that NaOH and FeCl in step two 3 The molar ratio is 4: 1, and others are the same as the specific embodiment one.

PUM

| Property | Measurement | Unit |

|---|---|---|

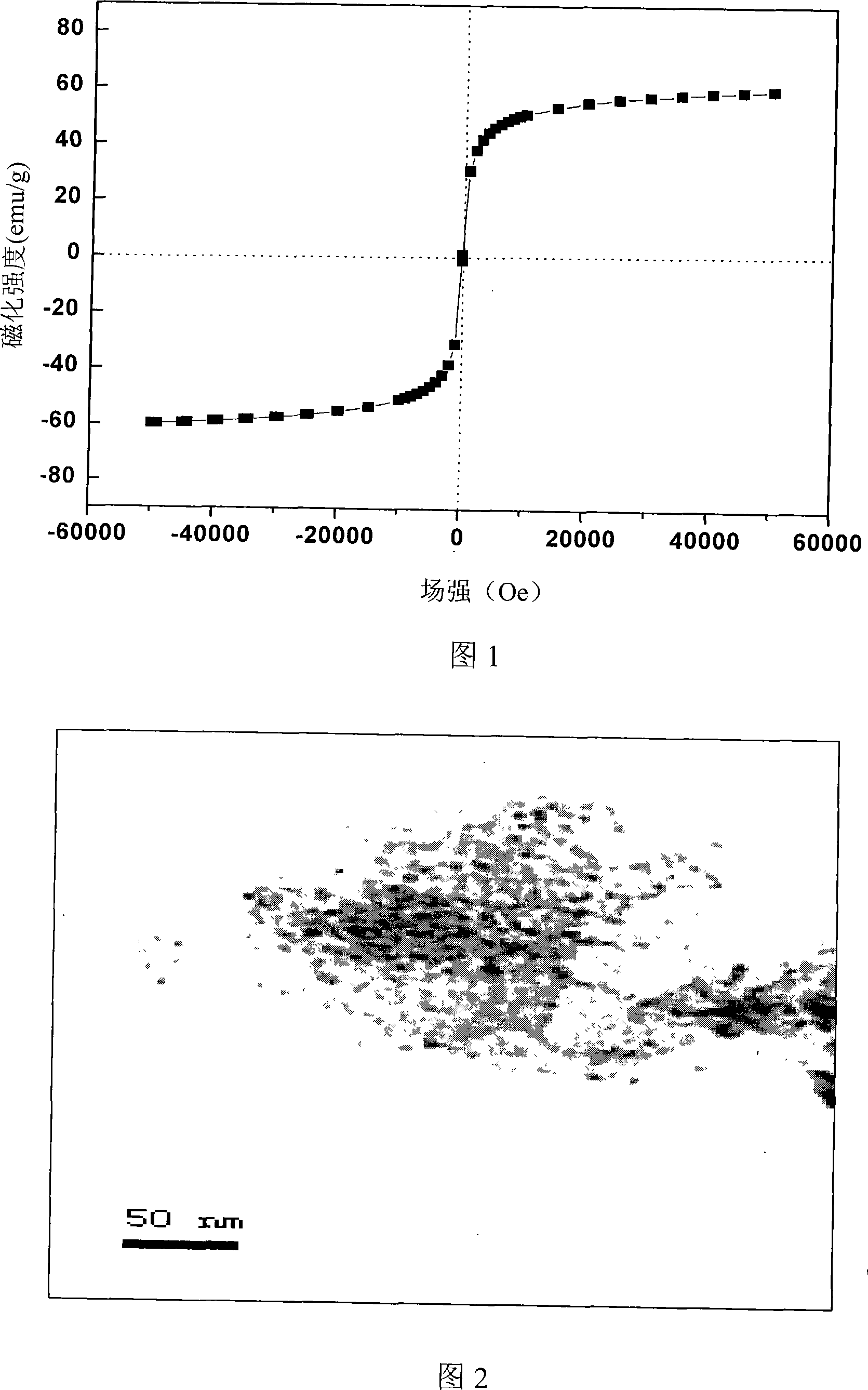

| Saturation magnetization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com