Method for qualifying industrial ammonium chloride products

A technology for industrial ammonium chloride and product quality, applied in the direction of ammonium halide and the like, can solve the problems of high production input requirements, unfavorable environmental protection, and high production costs, and achieve the effects of wide use, environmental protection, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

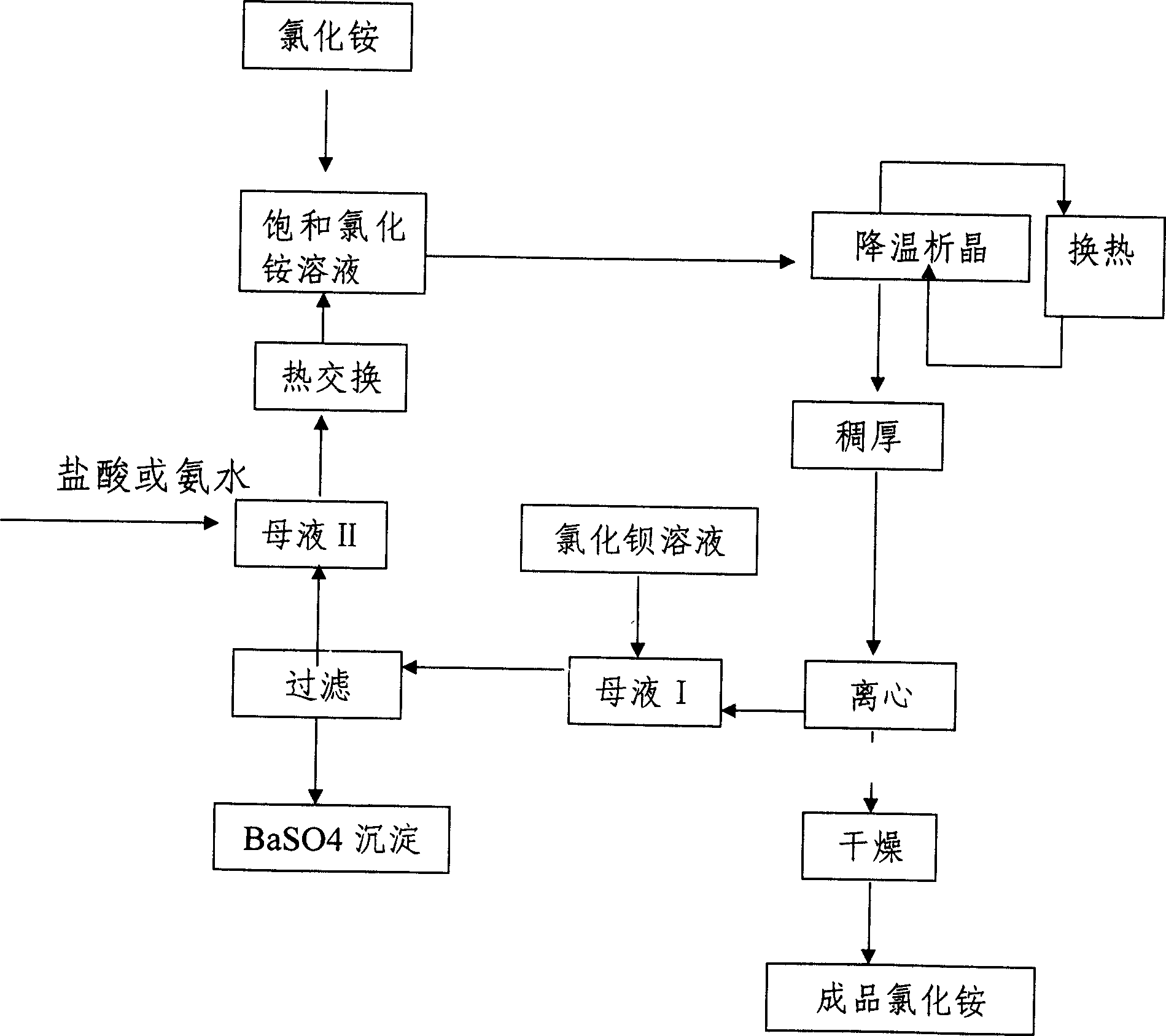

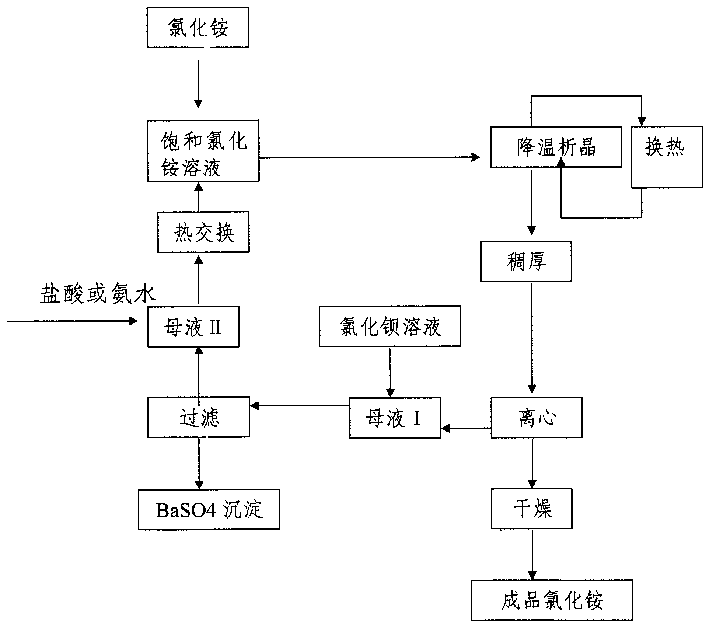

[0017] Example 1. Refer to attached picture. A method for improving the quality of industrial ammonium chloride product, the steps are as follows,

[0018] (1) Dissolve ammonium chloride into a saturated ammonium chloride solution with water at 50°C, wherein the sulfate ion SO in ammonium chloride 4 2- The content is about 0.05%;

[0019] (2) the ammonium chloride saturated solution is cooled to 12 DEG C again, and ammonium chloride crystals are separated out;

[0020] (3) Ammonium chloride crystallization liquid is improved solid-liquid ratio through thickener, after solid-liquid ratio reaches 16:84, enter centrifuge and carry out dehydration, dry, obtain finished product ammonium chloride, sulfate radical ion in finished product ammonium chloride SO 4 2- The content is about 0.01%;

[0021] (4) Add barium chloride solution that is not too much relative to the sulfate radical in mother liquor I in the mother liquor I that gets rid of when dehydrating in centrifuge agai...

Embodiment 2

[0023] Example 2. Refer to attached picture. A method for improving the quality of industrial ammonium chloride product, the steps are as follows,

[0024] (1) Dissolve ammonium chloride into a saturated solution of ammonium chloride with unsaturated ammonium chloride solution at 60°C, wherein the sulfate ion SO in ammonium chloride 4 2- The content is about 0.06%;

[0025] (2) the ammonium chloride saturated solution is cooled to 16 DEG C again, and ammonium chloride crystals are separated out;

[0026] (3) Ammonium chloride crystallization liquid is increased solid-liquid ratio through thickener, after solid-liquid ratio reaches 20:80, enter centrifuge and carry out dehydration, dry, obtain finished product ammonium chloride, sulfate radical ion in finished product ammonium chloride SO 4 2- The content is about 0.02%;

[0027] (4) Add barium chloride solution that is not too much relative to the sulfate radical in mother liquor I in the mother liquor I that gets rid o...

Embodiment 3

[0028] Example 3. Refer to attached picture. A method for improving the quality of industrial ammonium chloride product, the steps are as follows,

[0029] (1) Dissolve ammonium chloride into a saturated solution of ammonium chloride with an unsaturated ammonium chloride solution at 70°C, wherein the sulfate ion SO in ammonium chloride 4 2- The content is about 0.04%;

[0030] (2) cooling the saturated solution of ammonium chloride to 22° C. to separate out ammonium chloride crystals;

[0031] (3) Ammonium chloride crystallization liquid is increased solid-liquid ratio through thickener, after solid-liquid ratio reaches 25:75, enter centrifuge and carry out dehydration, dry, obtain finished product ammonium chloride, sulfate radical ion in finished product ammonium chloride SO 4 2- The content is about 0.005%;

[0032] (4) add in the mother liquor I that gets rid of when centrifuge dehydration again, add relative to the sulfate radical in mother liquor I not excessive c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com