Method for producing feed-grade monocalcium phosphate by dry method

A calcium dihydrogen phosphate, feed-grade technology, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of limited promotion, poor economic benefits, and high production costs, and achieve short technological processes, low production costs, and low production costs. Low environmental impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] React with 500Kg wet-process phosphoric acid and 197Kg calcium carbonate powder. The reaction equipment can be a vertical reactor with stirring, or a horizontal reactor or a tubular reactor. Wet-process phosphoric acid is calculated on the basis of 55wt% phosphorus pentoxide, the calcium carbonate content in calcium carbonate powder is 96wt%, and the water content is 0.1wt%. The semi-finished product of calcium dihydrogen phosphate is 611Kg, and the moisture content of the semi-finished product is between 7 and 18wt%. The semi-finished product- The 40-mesh material occupies more than 40%. After curing, it is dried by a drying furnace. The drying equipment can be a rotary cylinder dryer or a flash flow dryer. The inlet hot air temperature is 350°C, and the rotary dryer outlet temperature is 80°C. After drying A 534Kg product of calcium dihydrogen phosphate was obtained, and the moisture content of the dried product was controlled between 1 and 4wt%. Feed-grade calcium di...

Embodiment 2

[0032] Wet process purification of phosphoric acid and calcium carbonate powder according to the calcium / phosphorus ratio: 0.56 ~ 0.65, the ratio metered into the high-speed mixing reactor for reaction, control process indicators phosphorus pentoxide content in wet phosphoric acid 45 ~ 60wt%, acid temperature 50 ~ 80 ℃, the fineness of calcium carbonate powder -200 mesh is greater than 90wt%, the reaction temperature is 60-80 ℃, and the semi-finished product of calcium dihydrogen phosphate is produced, and the semi-finished product of calcium dihydrogen phosphate is dried by flash steam or rotary kiln to obtain the product of calcium dihydrogen phosphate.

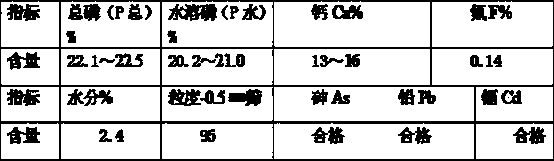

[0033] Product index table:

[0034]

[0035] The quality of the feed grade calcium dihydrogen phosphate produced by the above method complies with the national standard GB / T22548-2008:

[0036] project Index Total phosphorus (P) content / % ≥ 22.0 Water-soluble phosphorus (P) content / % ≥ 20.0 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com