High-silica porcelain rustic tile and production method thereof

A production method, the technology of antique bricks, applied in the field of ceramic tiles, can solve the problems of rising mineral raw material prices, increased mining, priceless market, etc., to achieve the effect of enhancing core competitiveness, reducing formula cost, and strong universality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

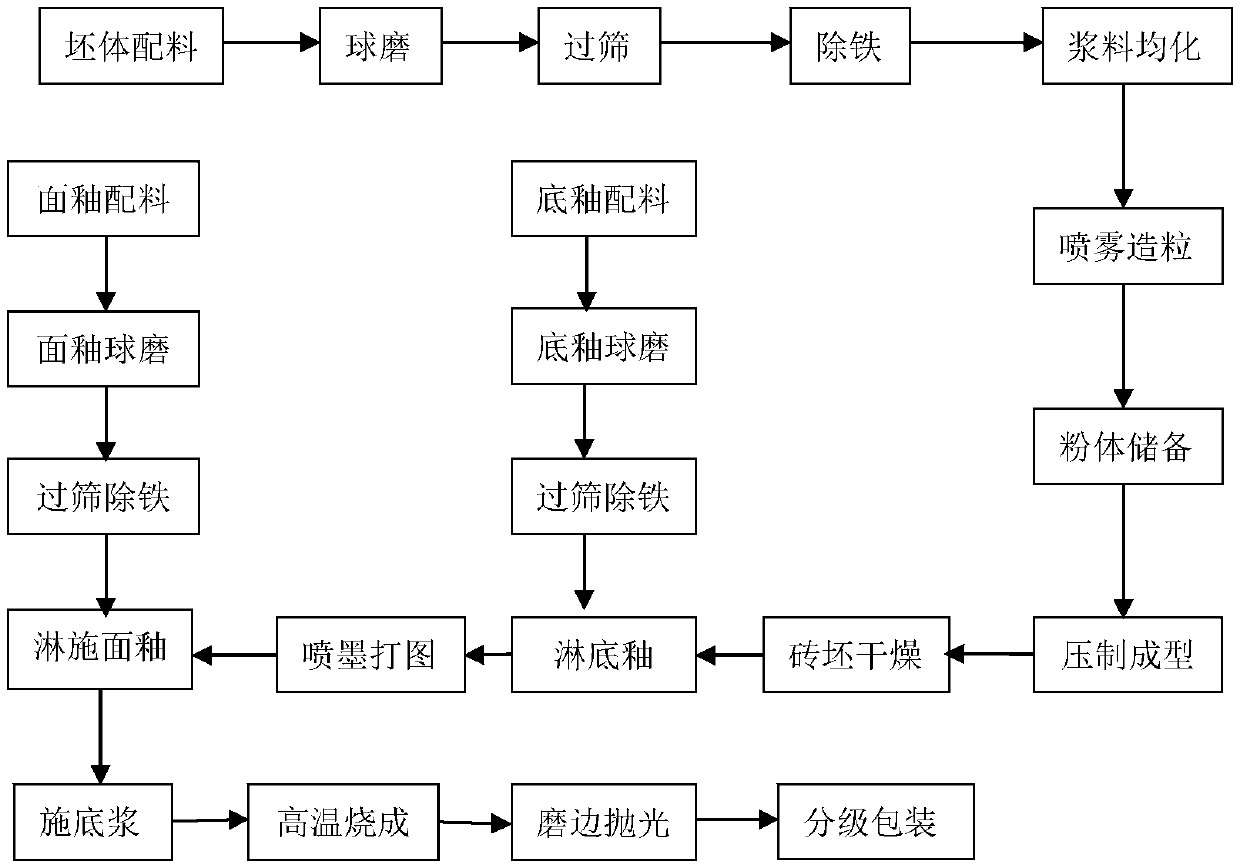

Method used

Image

Examples

Embodiment Construction

[0033] 1 Preparation of green body

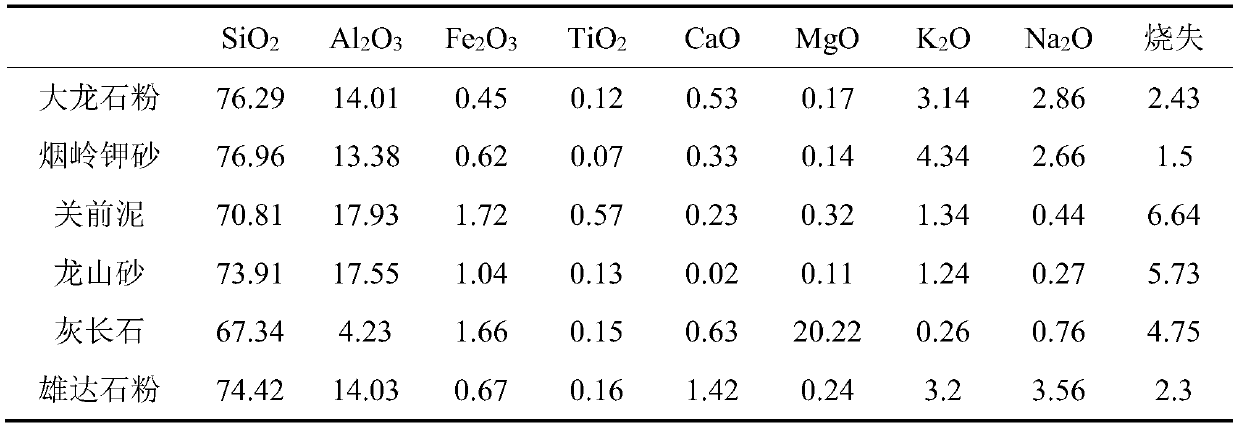

[0034] Table 1. Chemical composition of raw materials for high-silicon porcelain antique brick body

[0035]

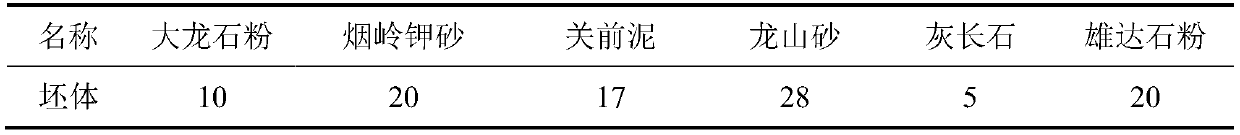

[0036] Table 2. Raw material formula composition of high-silicon porcelain antique brick

[0037]

[0038] Table 3. Body chemical composition of high-silicon porcelain antique brick

[0039]

[0040] Preparation of green body: According to the chemical composition of raw materials for high-silicon porcelain antique bricks in Table 1 and the composition of the green body formula in Table 2, select the corresponding proportion of Dalongshi powder, Yanling potash sand, Guanqian mud, Longshan sand, gray feldspar, Xiongda stone powder and auxiliary raw materials with a weight percentage of 1.5-2.5% are added, and an appropriate amount of water is added to be finely ground by ball milling into a 250-mesh sieve with a mass percentage of 0.7%-0.8% and a mass percentage of 35%- The slurry with 36% moisture is spray-dried by remov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com