Energy-saving carrier gas stripping system and stripping process

An energy-saving, carrier gas technology, used in fractionation, distillation separation, vacuum distillation, etc., can solve the problems of poor fractionation accuracy, high energy consumption, and high separation temperature, and achieve small equipment footprint, low separation temperature, and high separation accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

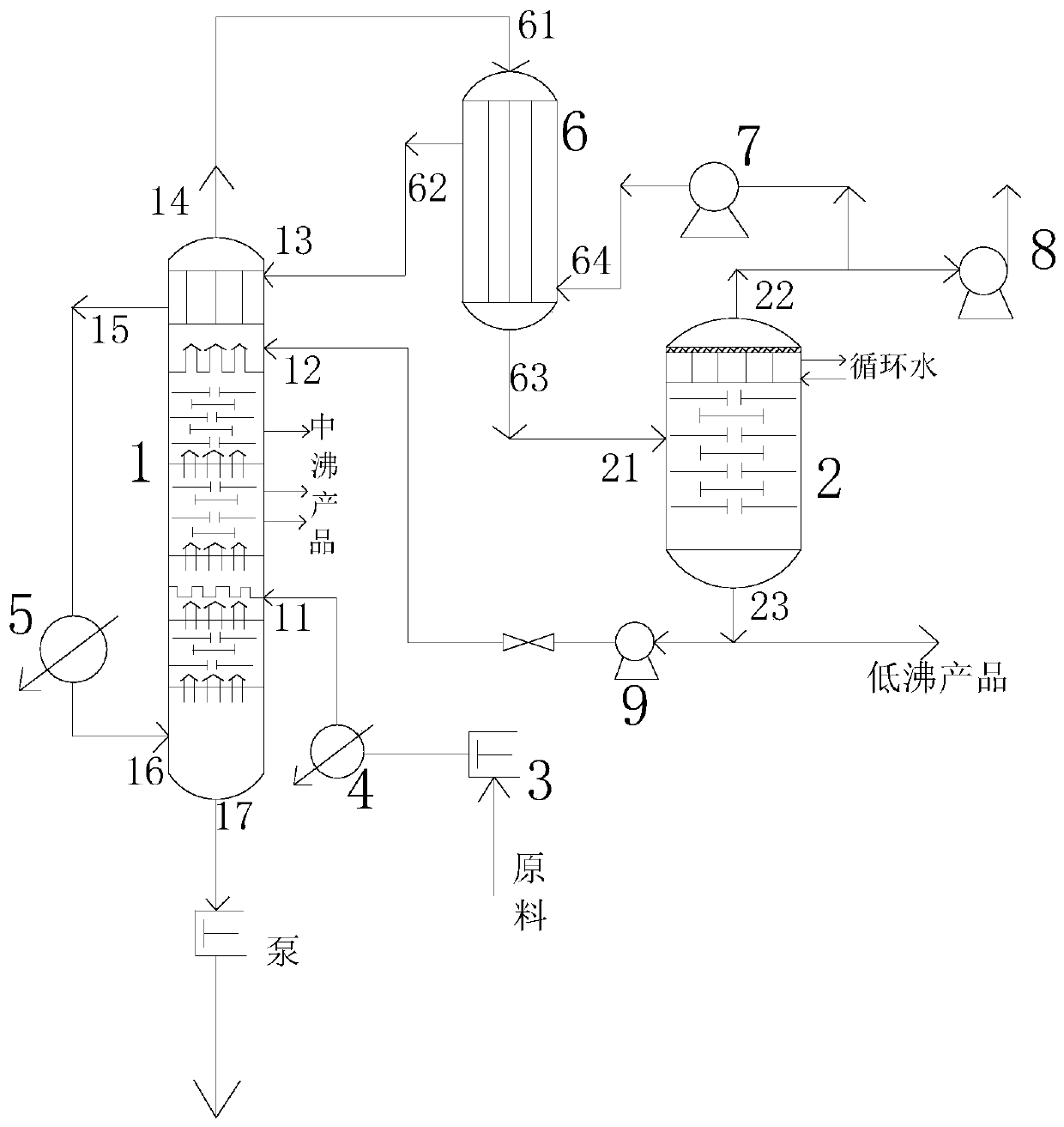

[0036] see figure 1 , an energy-saving carrier gas stripping system, comprising a stripping tower 1, a separation tank 2; a raw material heater 4; a carrier gas heater 5 and a gas circulation heat exchanger 6;

[0037] A heat-and-mass-transfer section is set in the stripping tower 1; specifically, a heat-and-mass-transfer section is set at the top of the stripping tower 1, so that the light components going up with the carrier gas pass through the heat-and-mass-transfer section for heat-exchanging and cooling , to reduce the temperature of the light components.

[0038] The stripping tower 1, the gas circulation heat exchanger 6 and the separation tank 2 are connected in sequence through pipelines; the gas circulation heat exchanger 6 is connected with the heat and mass transfer section through pipelines; the separation tank 2 is connected with the stripping tower 1 through pipelines ; The raw material heater 4 is connected to the stripping tower 1 through a pipeline; the hea...

Embodiment 2

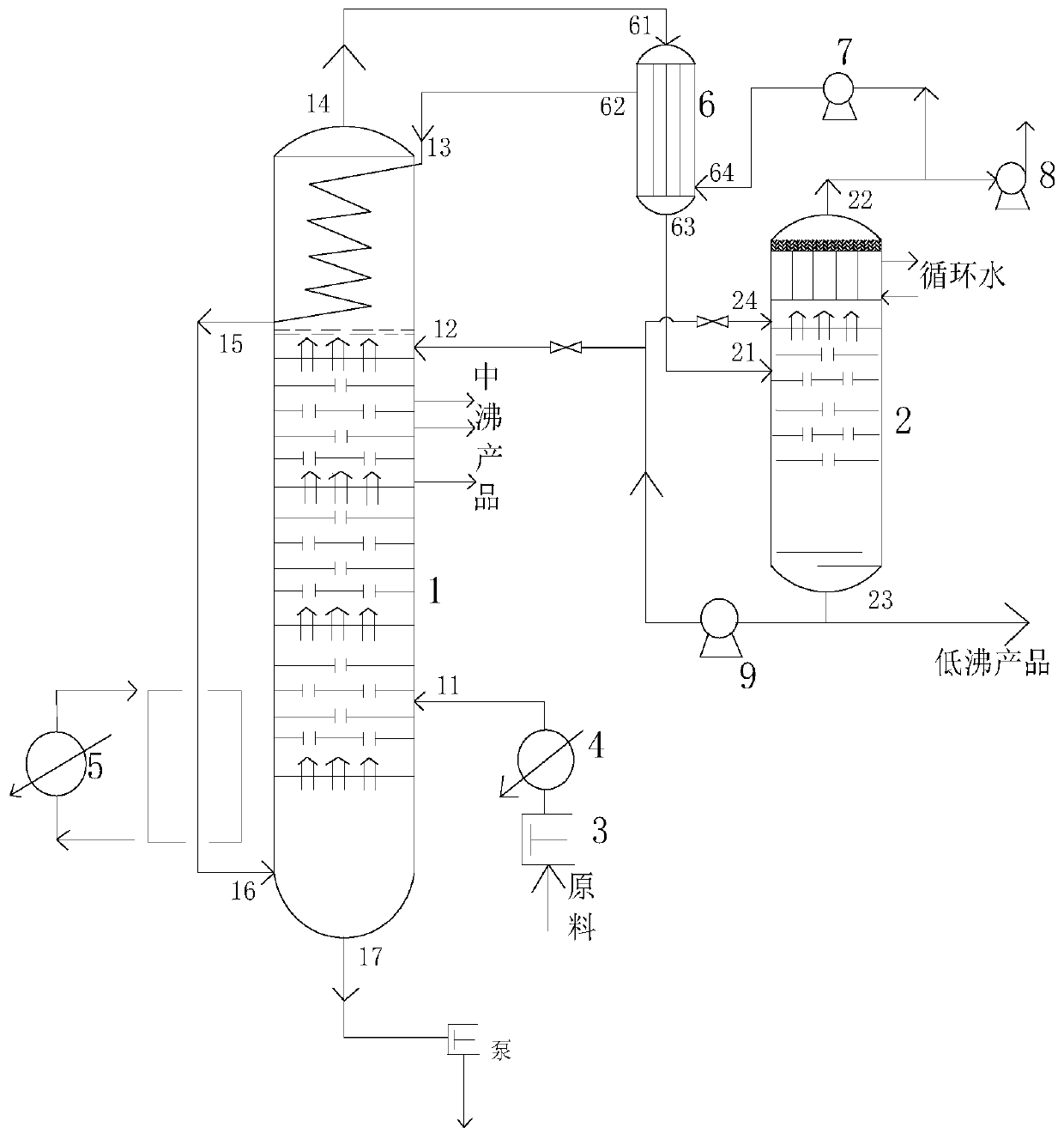

[0059] see figure 2 , an energy-saving carrier gas stripping system, comprising a stripping tower 1, a separation tank 2; a raw material heater 4; a carrier gas heater 5 and a gas circulation heat exchanger 6;

[0060] In this embodiment, the stripper 1 is provided with a raw material inlet 11, a light component reflux inlet 12, a carrier gas inlet 13, a light component outlet 14, a carrier gas outlet 15, a carrier gas circulation inlet 16 and a heavy component discharge port 17.

[0061] In this embodiment, a heat and mass transfer section is arranged at the top of the stripping tower 1; the heat and mass transfer section includes heat exchange tubes and fillers, the heat exchange tubes are coiled heat exchange tubes, and the fillers are placed in the coiled heat exchange tubes. external.

[0062] In this embodiment, the separation tank 2 is provided with a separation tank inlet 21 , a separation tank top outlet 22 , a separation tank bottom outlet 23 and a separation tank...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com