Production technology of ecological concrete

A technology of ecological concrete and production technology, which is applied in the field of building materials and resource recycling, can solve problems such as environmental pollution and occupation of land resources, and achieve the effects of reducing water absorption, simple preparation method, and improving aggregate strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

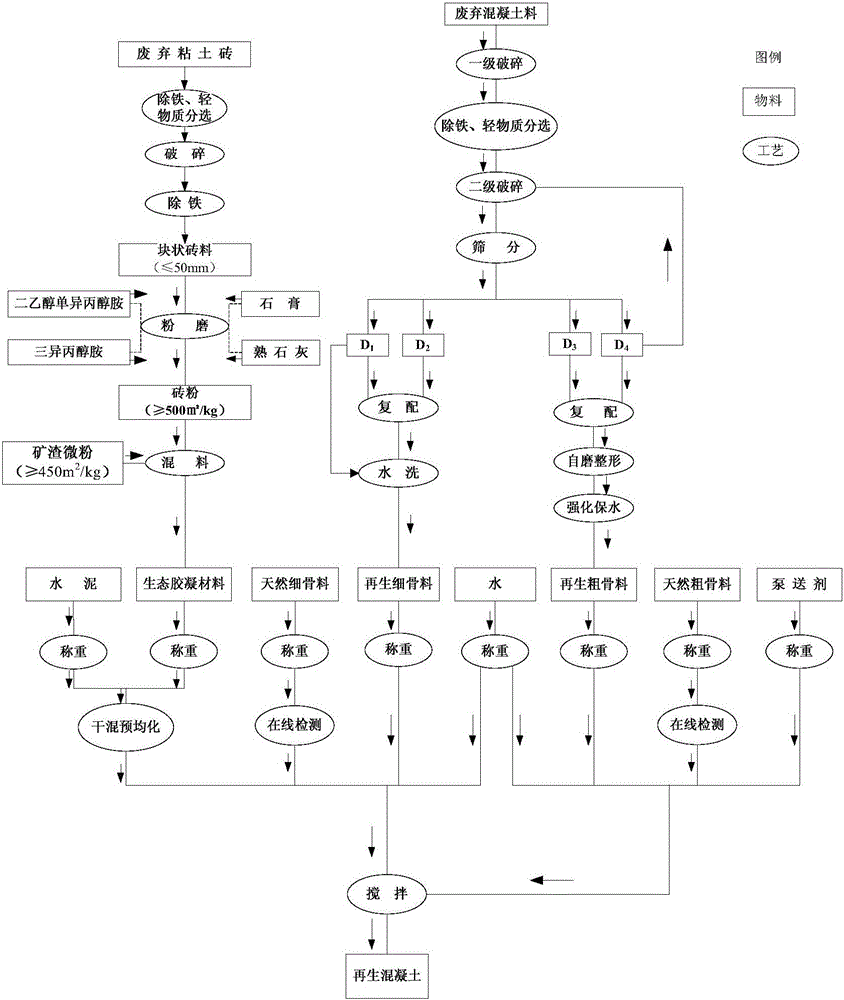

[0048] Such as figure 1 Shown, a kind of production technology of ecological concrete comprises the steps:

[0049] Step 1, preparation of ecological cementitious materials: the construction waste clay bricks sorted by the volume method are removed by magnetic separation device and light matter sorting device to remove iron and light matter, and crushed by crushing equipment into blocks with a size of ≤50mm Brick material, after magnetic separation, it is ultra-finely ground by a vertical mill to obtain a specific surface area ≥ 500m 2 / kg of clay brick powder, mixed with a certain proportion of chemical activator in the grinding process, and compounded with slag powder to prepare ecological cementitious materials;

[0050]Step 2, preparation of recycled aggregate: the waste concrete material sorted by the volume method is crushed through prim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Slump | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com