Apparatus and method for processing wastes

A technology for processing equipment and processing methods, applied in cement production, clinker production, coke ovens, etc., can solve problems such as low oxygen content, difficult combustion control, adverse effects of calciner combustion, etc., to reduce costs and improve energy utilization efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

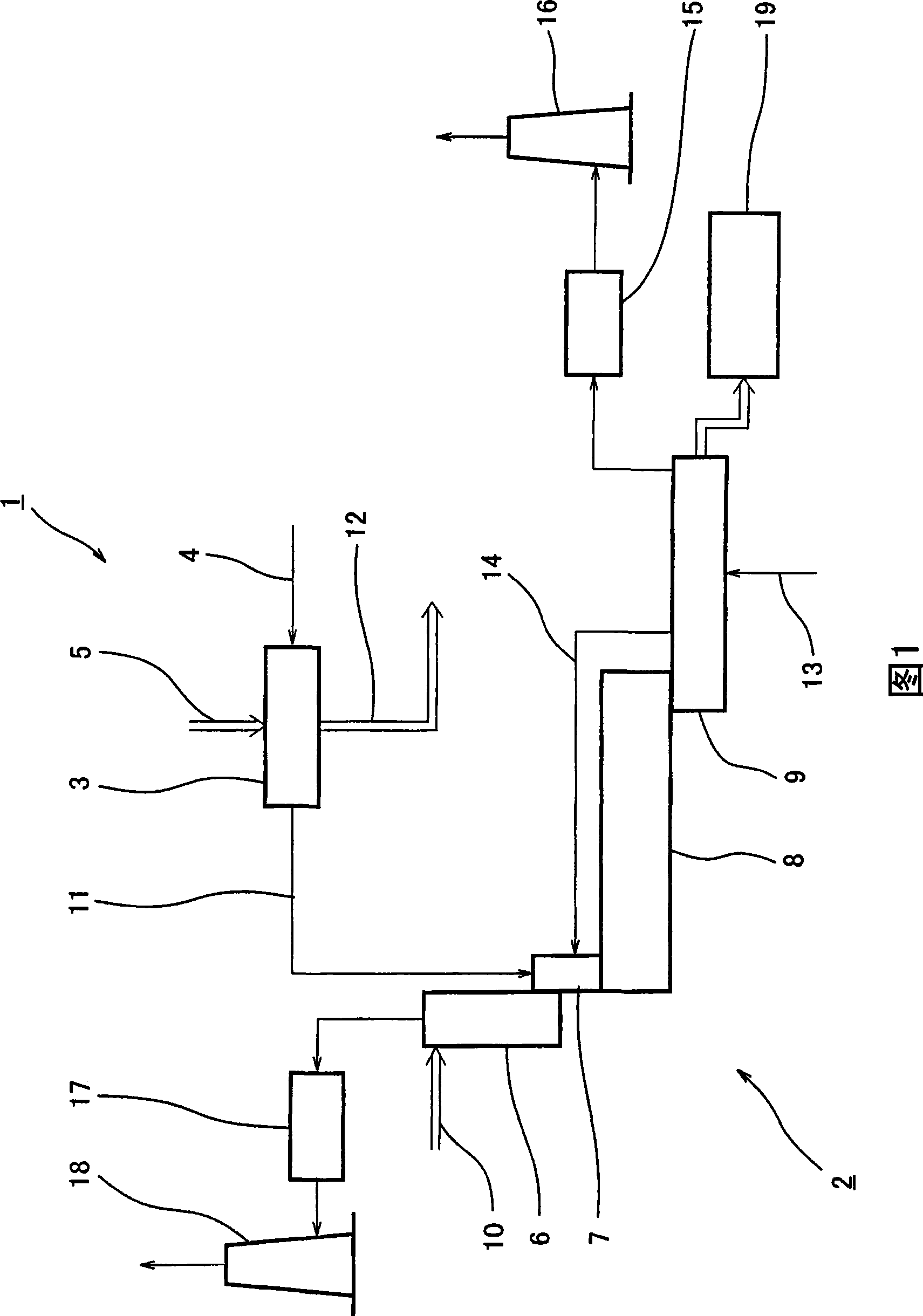

[0047] Embodiments of the waste treatment facility and the waste treatment method of the present invention will be described below with reference to the drawings. Fig. 1 is a block diagram showing an embodiment of the waste treatment facility of the present invention. Among the arrows representing the flow in the figure, the single-line arrow mainly indicates the flow of gas, and the double-line arrow mainly indicates the flow of solid.

[0048] The waste treatment facility 1 shown in FIG. 1 utilizes waste heat generated by the cement production plant 2 and uses part of the treated waste as cement raw material for the cement production plant 2 . FIG. 1 shows a fluidized-bed gasifier 3 constituting a part of a waste treatment facility 1 . The fluidized-bed gasification furnace 3 is a pyrolysis furnace, and the waste charged therein is thermally decomposed and treated hygienically. And in this gasifier 3, pyrolysis gas is generated. Gasifiers produce less gas than direct fire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com