High-magnesium moderate-heat portland cement and production method thereof

A Portland cement, high-magnesium technology, applied in cement production, clinker production and other directions, can solve problems such as unfavorable crack resistance of concrete

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

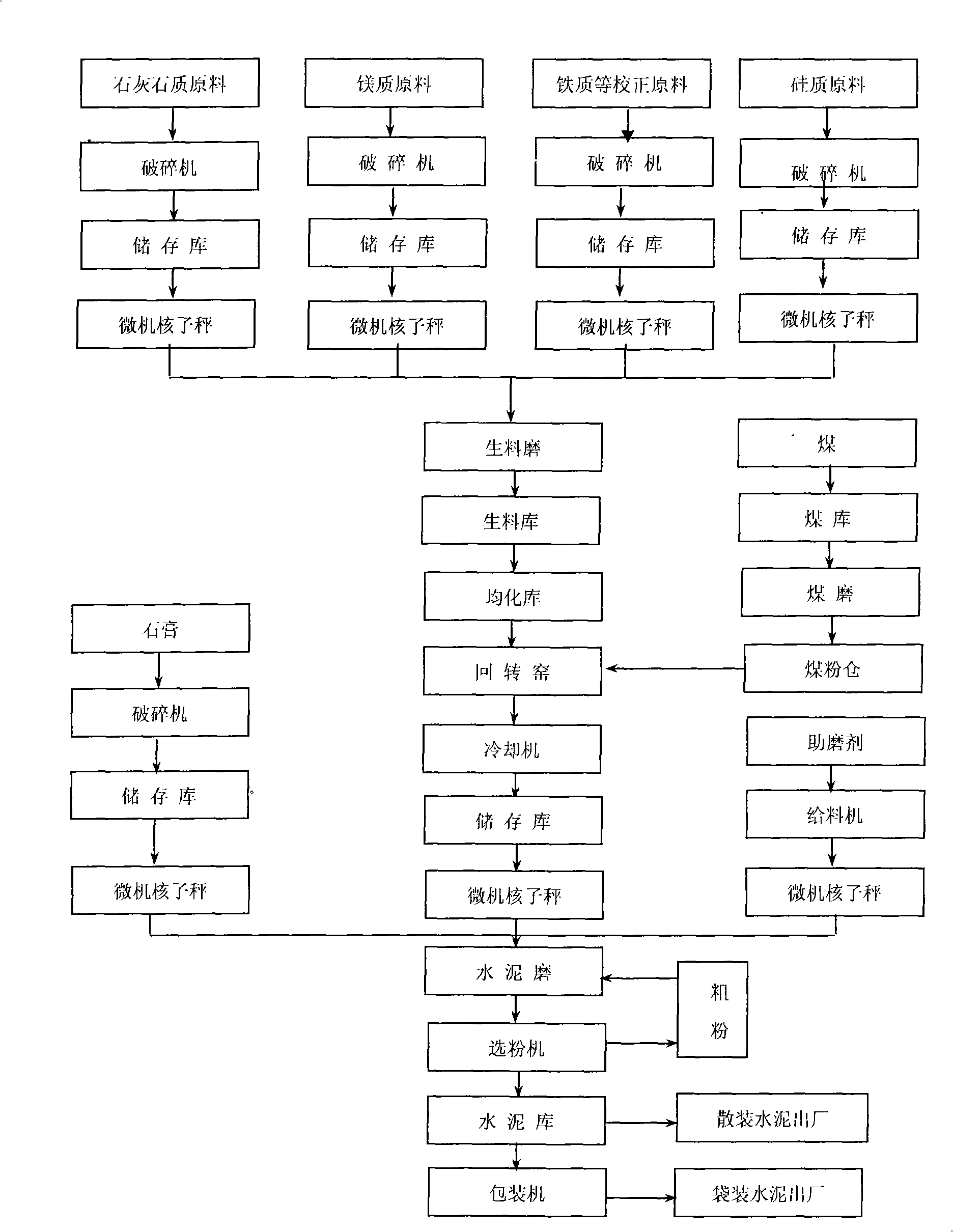

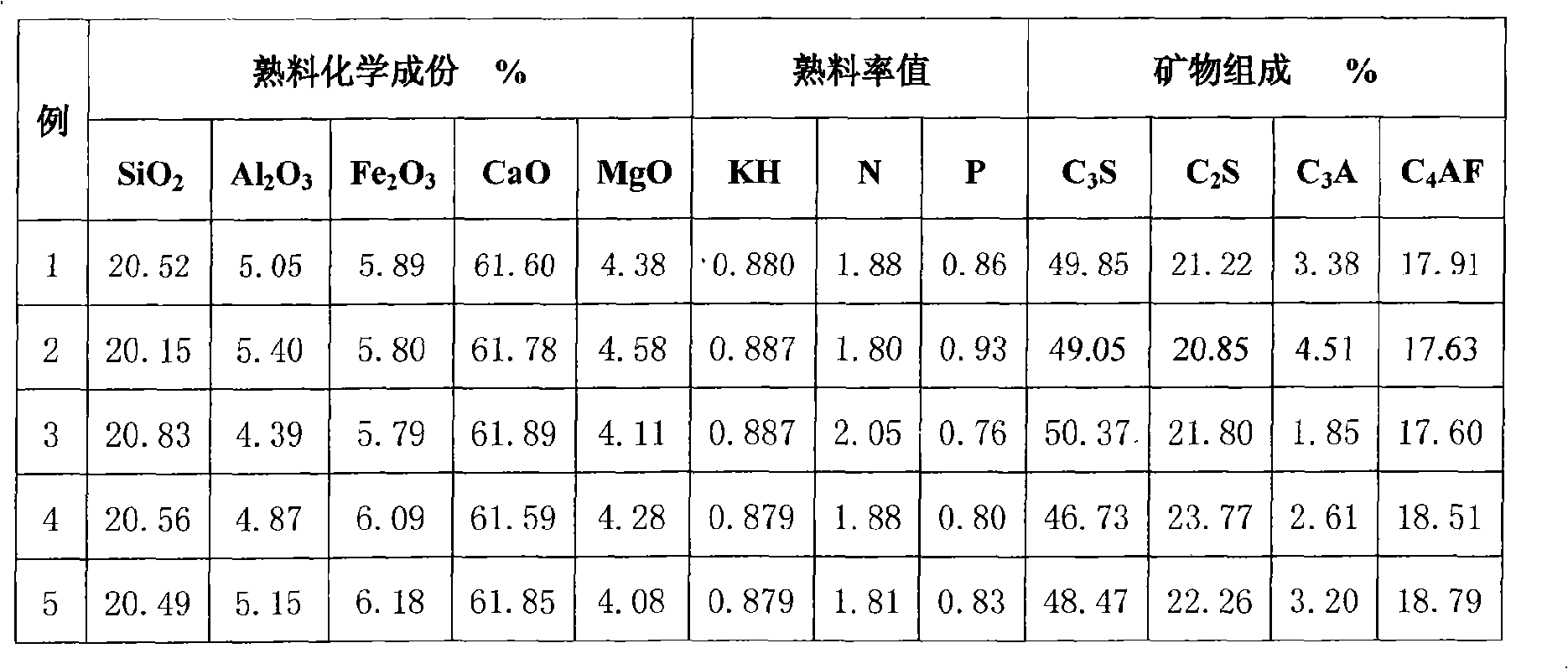

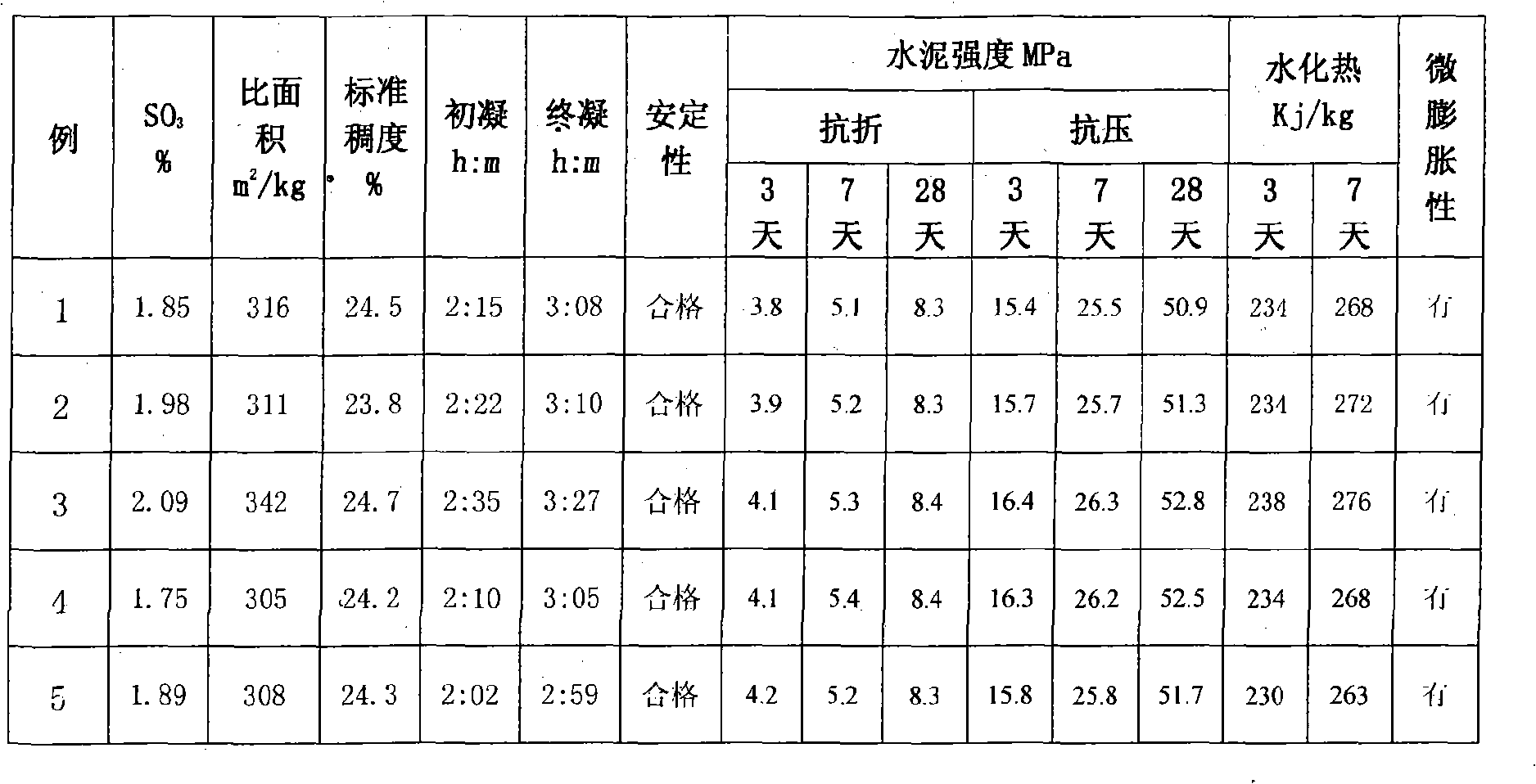

[0010] Embodiment 1: adopt proportioning as limestone: dolomite: coal gangue: sulfuric acid slag: silica sand=69.95: 8.85: 14.20: 5.11: 1.89 carries out batching, and raw material chemical composition sees 1, 3, 4, 8, 9 in Table 1 . High-magnesium medium-heat Portland cement clinker is calcined on a cement rotary kiln. See Example 1 in Table 2 for clinker composition, rate and mineral composition. The clinker is mixed with different types of gypsum as a retarder to grind high-magnesium medium-heat Portland cement. Its conventional physical properties are shown in Example 1 in Table 3. For detailed production process, see figure 1 production flow chart.

[0011] Table 1 Example 1 to 5 Raw material chemical composition %

[0012] serial number

name

LOSS

SiO 2

Al 2 o 3

Fe 2 o 3

CaO

MgO

SO 3

∑

1

limestone

41.10

3.78

1.39

0.48

50.86

1.15

/

98.76

2

...

Embodiment 2

[0017] Embodiment 2: The proportioning is limestone: high magnesium limestone: coal gangue: sulfuric acid slag: silica sand=32.85: 46.78: 13.12: 5.42: 1.83 for batching, and the chemical composition of raw materials is shown in 1, 2, 4, 8 in Table 1 , 9, produce high-magnesium medium-heat Portland cement clinker and cement with the method of embodiment one, and its clinker composition, rate value and mineral composition are shown in example 2 in Table 2, and the conventional physical properties of cement are shown in Example 3 in Table 3 2.

Embodiment 3

[0018] Embodiment three: adopt proportioning to be limestone: dolomite: stone coal slag: sulfuric acid slag: fly ash=68.71: 10.95: 9.78: 5.55: 5.01 carries out batching, and raw material chemical composition sees 1,3,5,8, in table 1 10. Use the method of Example 1 to produce high-magnesium medium-heat Portland cement clinker and cement. The clinker composition, rate and mineral composition are shown in Example 3 in Table 2. The conventional physical properties of cement are shown in Example 3 in Table 3. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com