Modified low-alkalinity sulphoaluminate cement

A sulfoaluminate cement, low alkalinity technology, used in cement production, climate sustainability, sustainable waste disposal, etc. The surface of the product is easy to "sand", which affects the strength of components, so as to achieve the effect of easy quality assurance, environmental protection and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

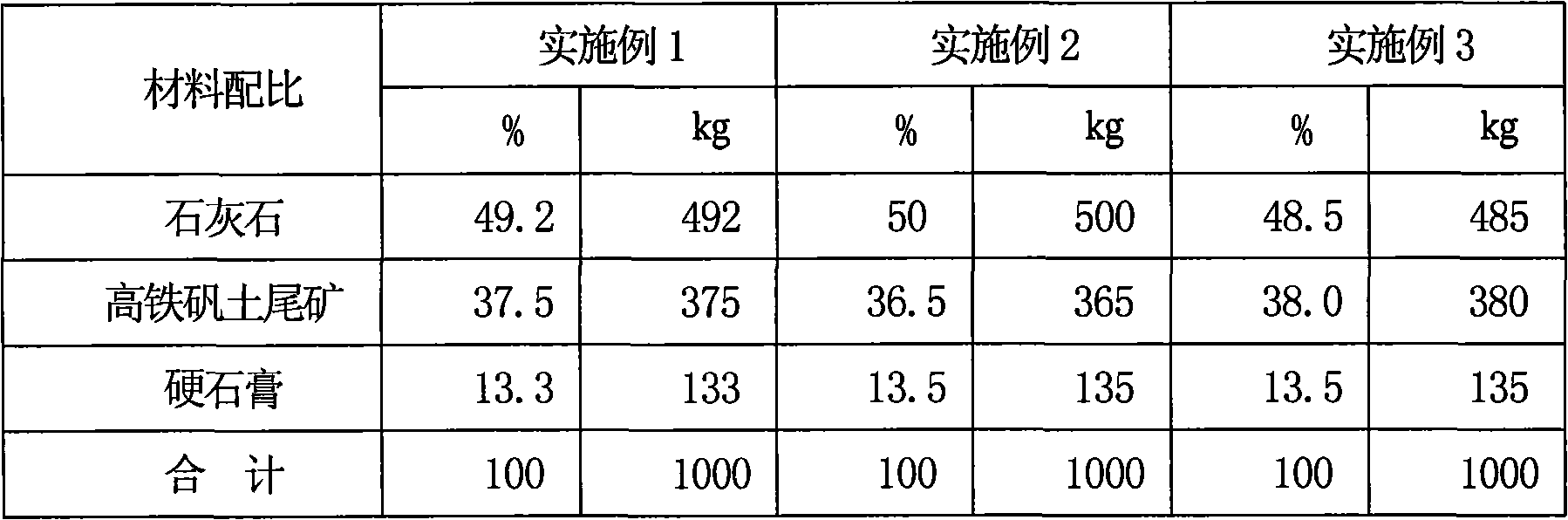

[0023] Table 1. Raw material ratio

[0024] Using high iron bauxite tailings ratio

[0025]

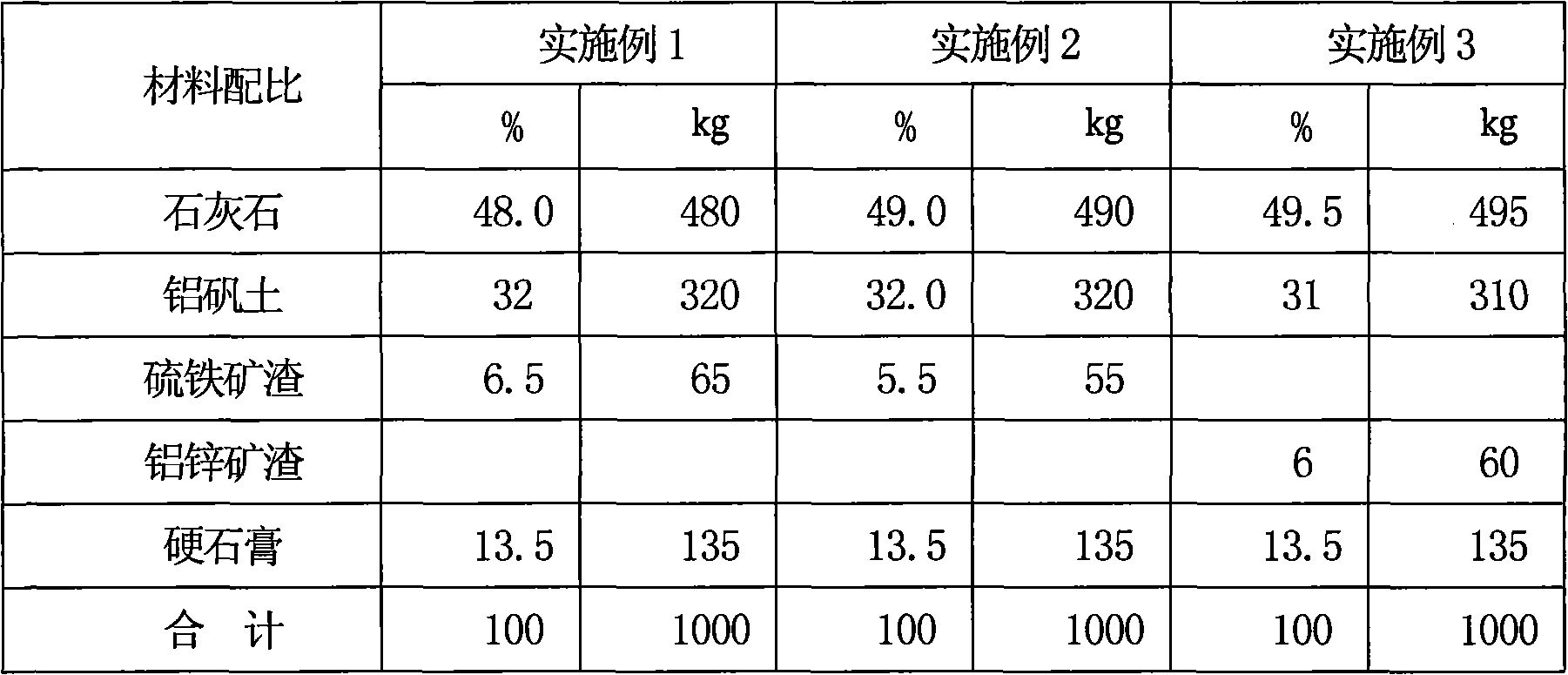

[0026] The ratio of bauxite, pyrite slag, and aluminum-zinc slag is adopted

[0027]

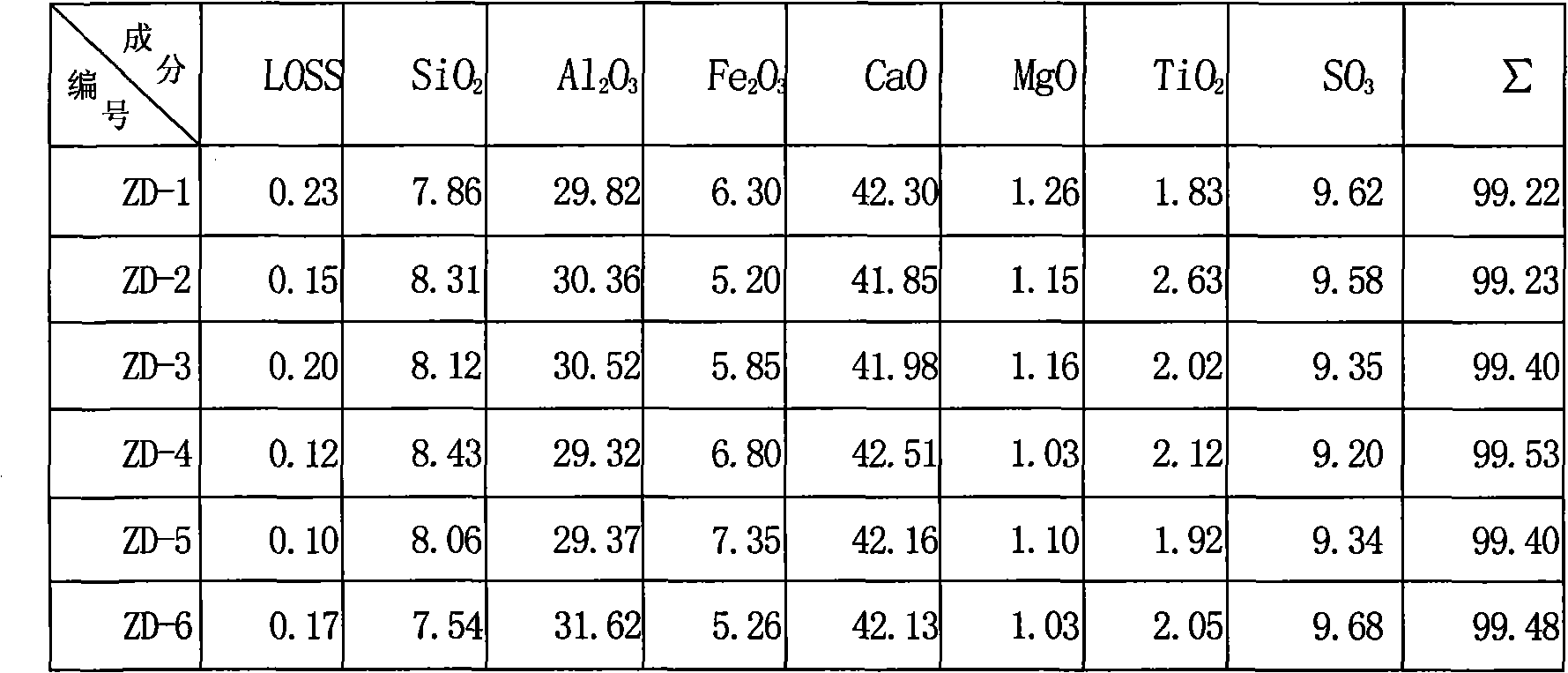

[0028] Table 2. Chemical composition of clinker

[0029]

[0030] Table 3. Proportion of modified low-alkalinity sulfoaluminate cement of the present invention

[0031]

[0032] The anhydrite in the above-mentioned embodiment of the present invention is natural anhydrite, requires SO in the anhydrite 3 ≥46%, it can also be mixed with one or more of dihydrate gypsum, dehydrated phosphogypsum, and fluorine gypsum, requiring SO 3 ≥42%.

[0033] The mixed material is limestone, requiring CaO ≥ 52%, mud content 2%, and can also be replaced by one or two or three mixtures of fly ash, slag and coal gangue.

[0034] The coagulation regulator is industrial boric acid with a content ≥ 98%.

[0035] The production process flow of the present invention is such that at first limestone, iron bau...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com