Water-washing pretreatment and cement kiln cooperated recycling disposal system for garbage fly ash

A waste water treatment system, garbage fly ash technology, applied in multi-stage water treatment, water/sewage treatment, water/sewage multi-stage treatment, etc., can solve problems such as cement kiln damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

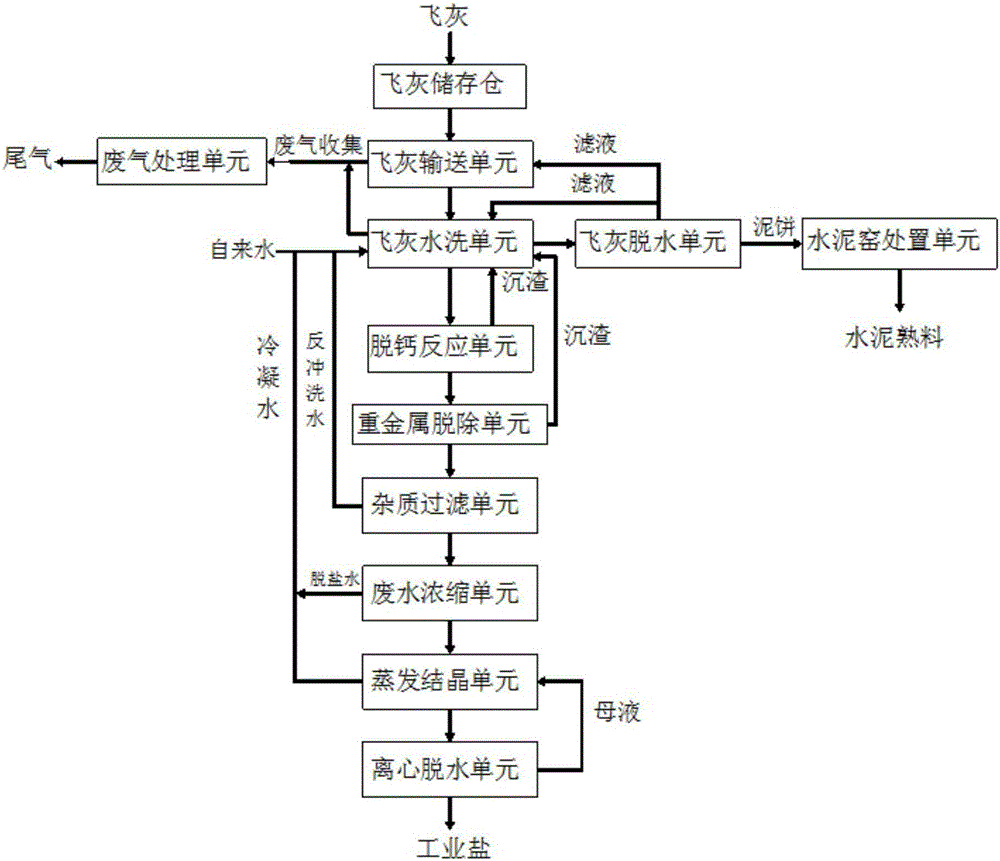

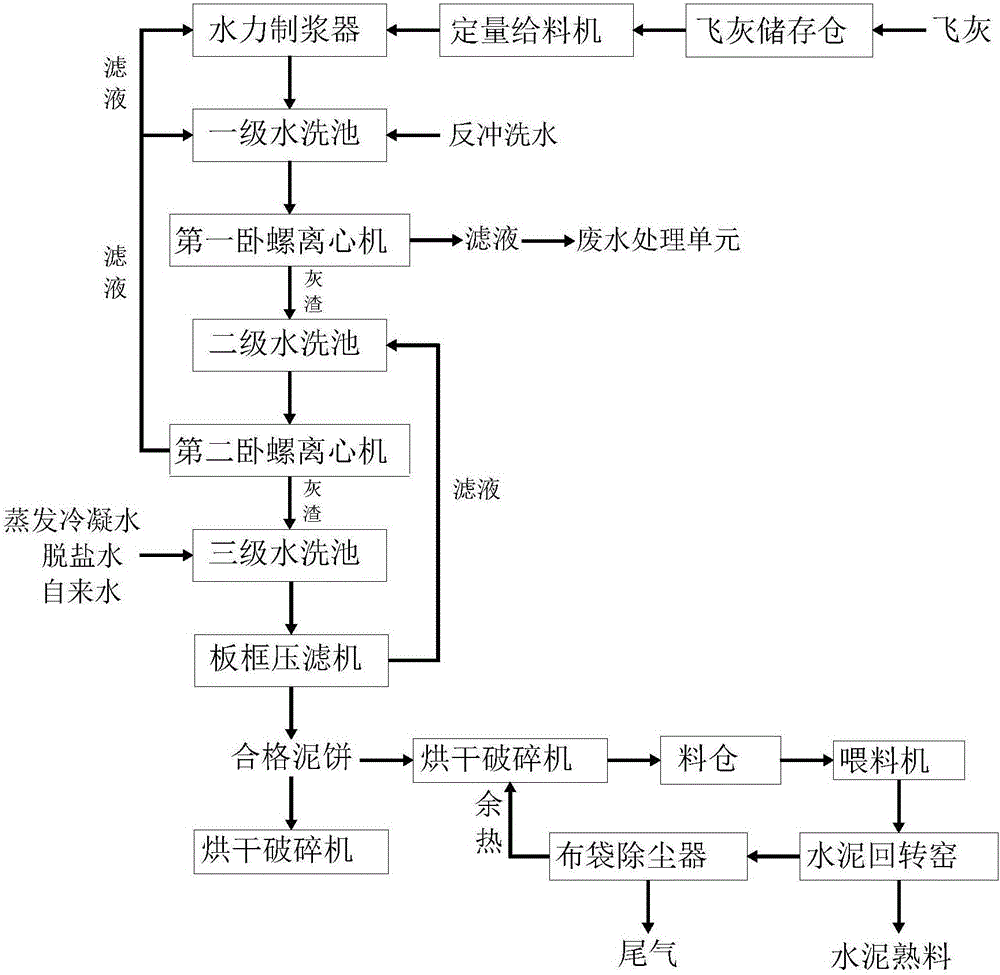

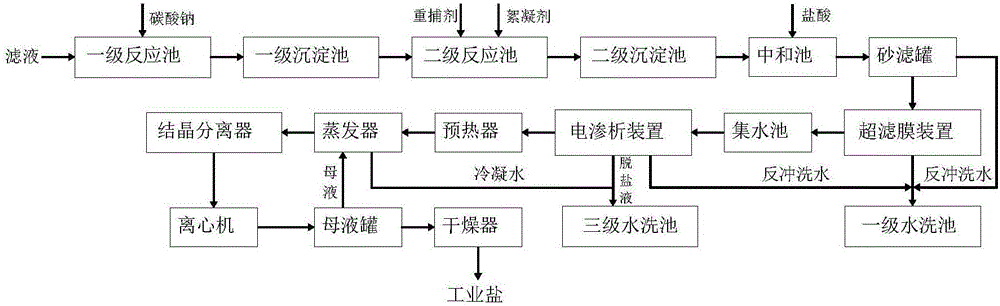

[0039] figure 1 The main flow chart of the garbage fly ash water washing pretreatment and cement kiln collaborative resource disposal system provided by the embodiment of the present invention; figure 1 As shown, the present invention provides a waste fly ash washing pretreatment and cement kiln collaborative resource disposal system, including: fly ash conveying unit, fly ash disposal system, waste water treatment system, cement kiln disposal unit connected in sequence; fly ash The conveying unit is used to transport the fly ash to the fly ash treatment system; the fly ash treatment system is used to remove chloride ions and heavy metals in the fly ash; the waste water treatment system is used to treat the fly ash washing wastewater to meet the standard for reuse, At the same time, industrial salt with application value is extracted; the cement kiln disposal unit is used for high-temperature calcination of the treated fly ash to decompose harmful components such as dioxins an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com