Polycrystal flexible tile joint mixture

A technology of polycrystalline and caulking agent, which is applied in the field of building materials, can solve problems such as unfavorable fast cleaning, slow condensation speed, and sticky caulking agent, and achieve the effect of improving waterproof effect, compressive strength, and waterproof function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0017] A polycrystalline flexible ceramic tile joint sealant, the composition and mass parts proportion of the polycrystalline flexible ceramic tile joint sealant are as follows: 40 parts of cement, 5 parts of high alumina cement, 55 parts of quartz sand, 1 part of redispersible latex powder, 0.4 parts of silicone water repellent, 0.3 parts of hydroxypropyl methylcellulose ether, 5 parts of heavy calcium, 2 parts of bentonite, 5 parts of water glass, and 7 parts of slag powder.

Embodiment 3

[0019] A polycrystalline flexible ceramic tile joint sealant, the composition and mass fraction of the polycrystalline flexible ceramic tile joint sealant are as follows: 38 parts of cement, 4 parts of high alumina cement, 51 parts of quartz sand, 0.8 parts of redispersible latex powder, 0.3 parts of silicone water repellent, 0.25 parts of hydroxypropyl methylcellulose ether, 4 parts of heavy calcium, 1.5 parts of bentonite, 4.5 parts of water glass, and 5 parts of slag powder.

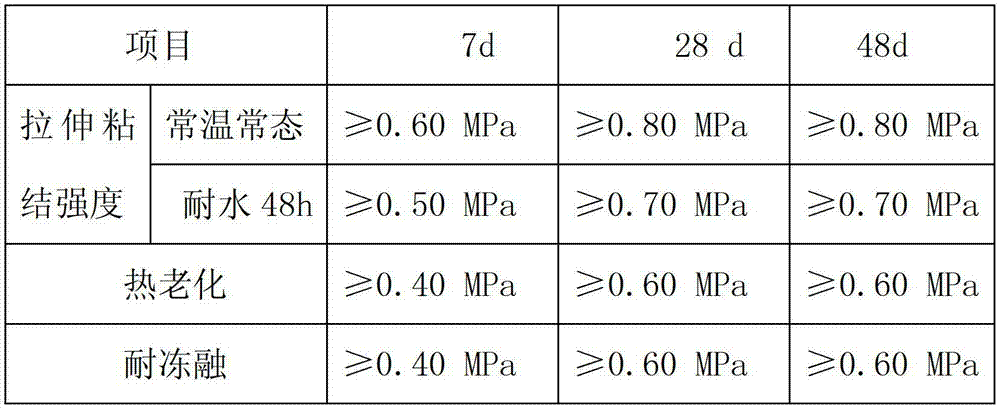

[0020] Based on the above examples, the comparison of technical indicators between the present invention and the prior art cement-based tile grout is as follows: 1. Comparison of technical indicators in different time periods without adding cellulose ether (HPMC).

[0021]

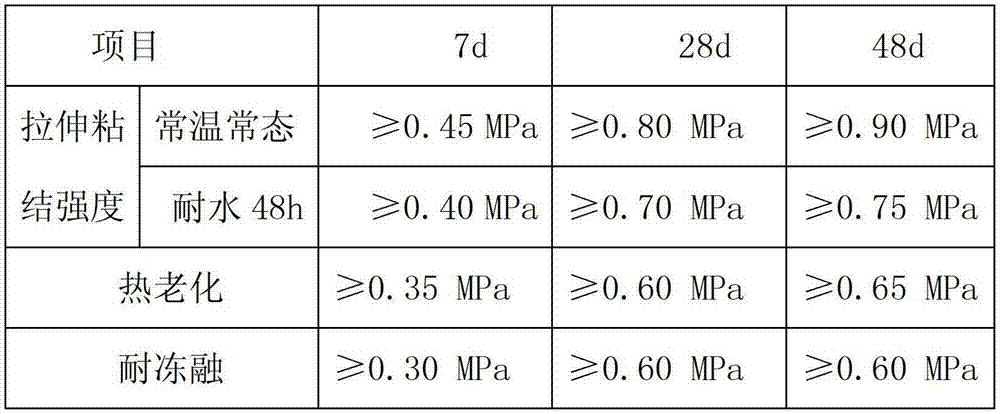

[0022] Comparison of technical indicators of adding cellulose ether (HPMC) in different time periods.

[0023]

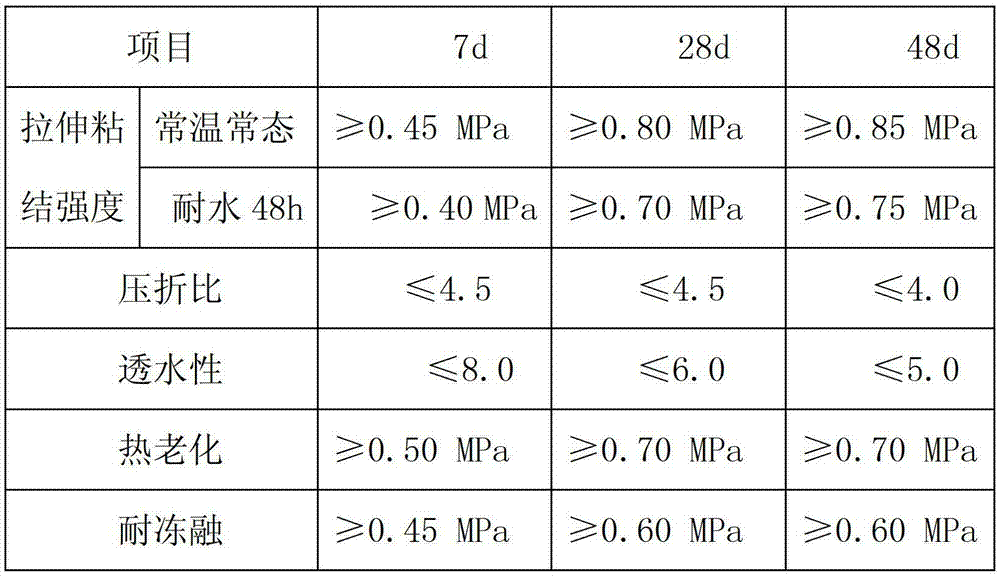

[0024] 2. Comparison of technical indicators in different time periods without adding water glass, slag, and he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com