Compound conditioning and deep dewatering method of sludge

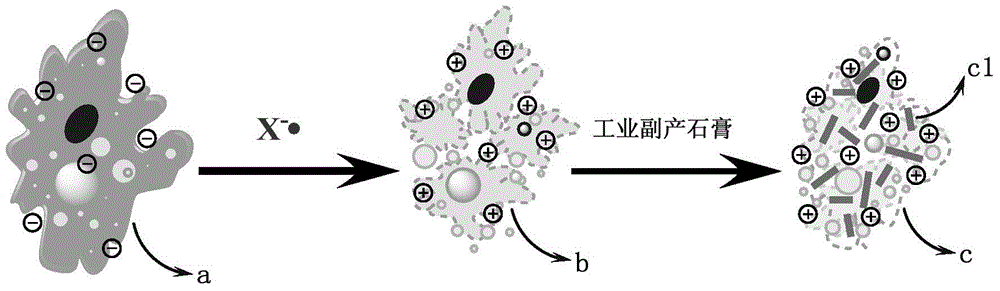

A deep dewatering and sludge technology, which is applied in dewatering/drying/concentrating sludge treatment, sludge oxidation treatment, etc., can solve the problems of large dosage and limited water content reduction in the de-cemented cake, and can improve the porosity and process. Simple, conditionally controlled effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

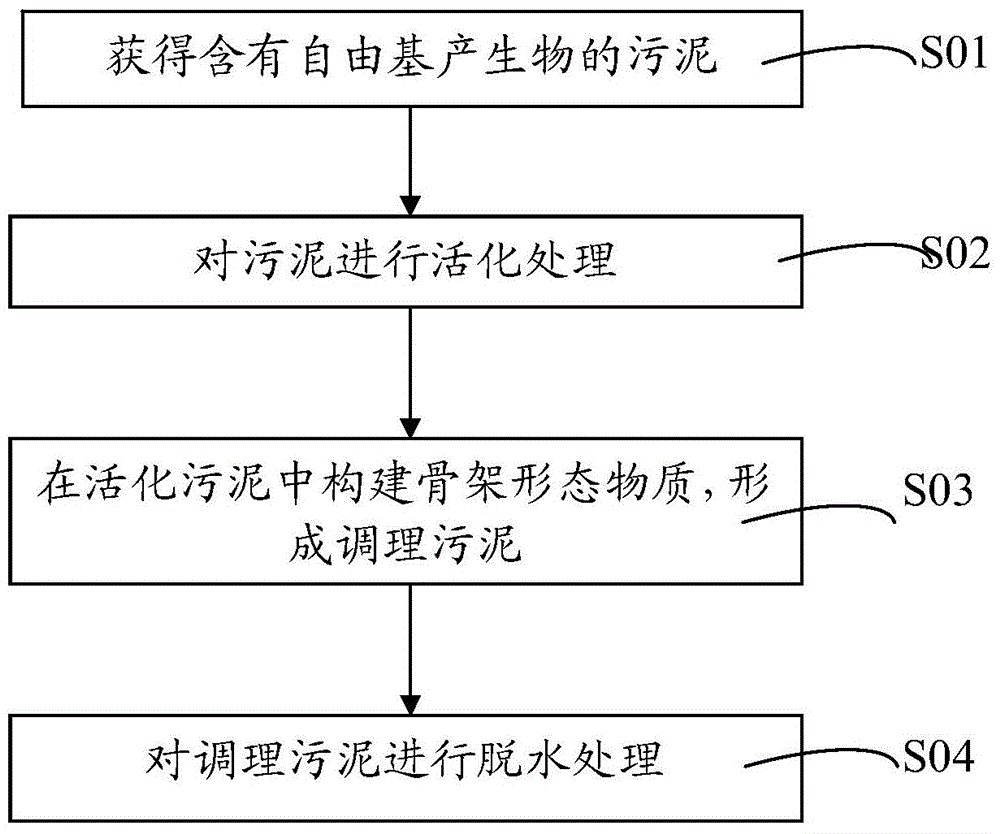

[0061] A compound conditioning method for deep dehydration of sludge, the process steps are as follows:

[0062] S11: Starting from the remaining sludge with an organic content of 50.8wt% and a moisture content of 96.7% by weight, add 10wt% peroxydisulfate to the sludge and stir thoroughly;

[0063] S12: Add 1.8wt% of nano-zero-valent iron on the dry basis of the sludge to the sludge treated in step S11, and fully stir for 15 minutes to complete the active free radical conditioning sludge;

[0064] S13: Then, add 30wt% phosphogypsum to the conditioned sludge in step S12, and stir for 5 minutes to complete the composite conditioning;

[0065] S14: The sludge conditioned in step S13 is subjected to plate and frame dehydration treatment.

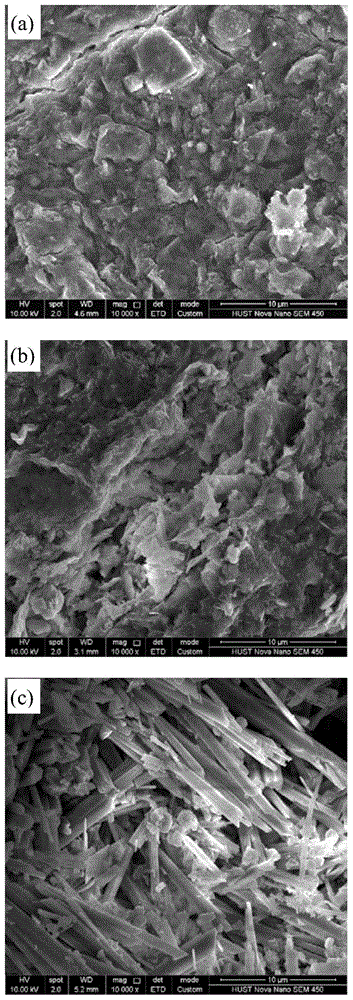

[0066] After testing, S12 sludge filtration specific resistance is 1.67×10 of raw sludge 13 m / kg drops to 1.51×10 12 m / kg, the sludge capillary water absorption time is reduced from 320.8s of the original sludge to 59.5s, and the specific resistance of S...

Embodiment 2

[0068] A compound conditioning method for deep dehydration of sludge, the process steps are as follows:

[0069] S21: Starting from the remaining sludge with an organic content of 43.86wt% and a moisture content of 95.3wt%, add 8wt% peroxydisulfate on the sludge dry basis to the sludge, and stir thoroughly;

[0070] S22: Add 1.5wt% of nano-zero-valent iron on the dry basis of the sludge to the sludge treated in step S21, and fully stir for 10 minutes to complete the active free radical conditioning sludge;

[0071] S23: Subsequently, add 10wt% phosphogypsum to the conditioned sludge in step S22, and stir for 10 minutes to complete the composite conditioning;

[0072] S24: The sludge conditioned in step S23 is subjected to plate and frame dehydration treatment.

[0073] After testing, S22 sludge filtration specific resistance is 1.61×10 of raw sludge 13 m / kg drops to 1.42×10 12 m / kg, the sludge capillary water absorption time decreased from 187.7s of the original sludge to 62.8s, and the...

Embodiment 3

[0075] A compound conditioning method for deep dehydration of sludge, the process steps are as follows:

[0076] S31: Starting from the centrifuge de-cemented cake with an organic content of 50.6wt% and a moisture content of 82.0wt%, add water to slurry to a moisture content of 91.7wt%, and then add 3.3wt% of dry sludge to the sludge Nano zero-valent iron, stir well;

[0077] S32: Add 10wt% of the monoperoxysulfate radical generator on the dry basis of the sludge to the sludge treated in step S31, and fully stir the sludge for 30 minutes to complete the active radical conditioning of the sludge;

[0078] S33: Subsequently, 15wt% desulfurized gypsum and 10wt% citrate gypsum are added to the conditioned sludge in step S32, and mixed for 8 minutes to complete the composite conditioning;

[0079] S34: The sludge conditioned in step S33 is subjected to a plate and frame dehydration treatment.

[0080] After testing, the specific resistance of S32 sludge filtration is 1.24×10 when the water ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com