Rapid-hardened super-early strength polycarboxylate water reducer and preparation method thereof

A technology of strong polycarboxylic acid and water-reducing agent, applied in the field of building admixtures, can solve the problems of not mentioning the fast setting effect, not considering the easy decomposition of 4-hydroxybutane, and accelerating the hydration of cement, so as to shorten the plastering and The effect of initial setting time, promoting cement hydration reaction and accelerating construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

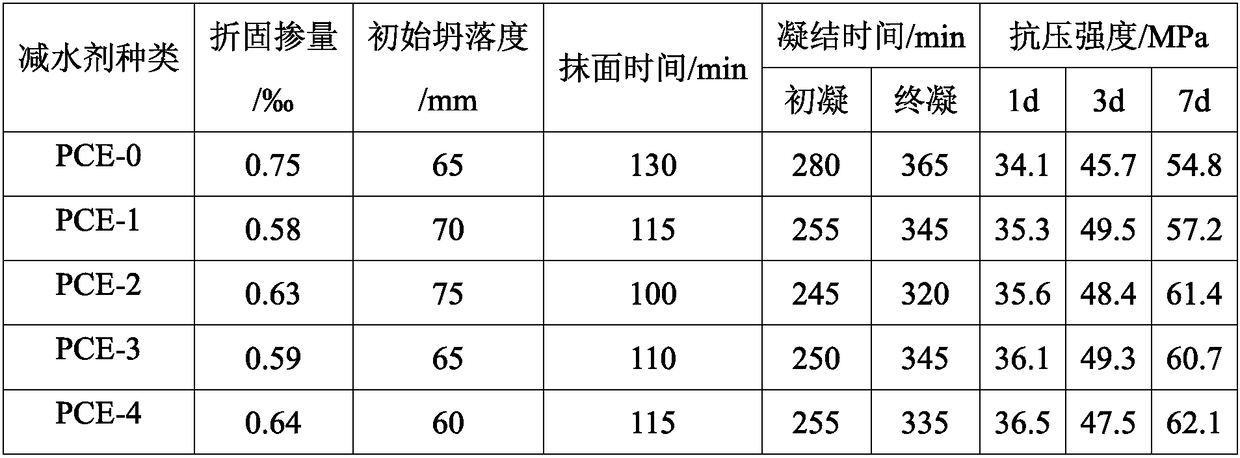

Examples

preparation example Construction

[0027] The preparation method of unsaturated alcohol amine ester small monomer in following embodiment comprises the steps:

[0028] (1) Acrylic acid and N, N-diethylethanolamine are joined in the reaction container that condensing device is housed in molar ratio 2.0: 1.2;

[0029] (2) Inject nitrogen gas while stirring, heat up to 55°C, add p-benzoquinone, stir for 20 minutes, p-quinone accounts for 1.0% of the total mass of acrylic acid and N,N-diethylethanolamine;

[0030] (3) Continue to heat up to 110°C, add phosphorous acid and react at a constant temperature for 4 hours, and phosphorous acid accounts for 1.2% of the total amount of acrylic acid and N,N-diethylethanolamine;

[0031] (4) After the reaction is stopped, the unreacted acrylic acid is distilled off under reduced pressure to obtain the small unsaturated alcohol amine ester monomer.

Embodiment 1

[0033] (1) Weigh each raw material component according to the following parts by weight: 200 parts by weight of allyl polyoxyethylene polyether with a molecular weight of 5000, 15 parts by weight of acrylic acid, 4 parts by weight of hydroxyethyl acrylate, a small unit of unsaturated alcohol amine ester 5 parts by weight of body, 2 parts by weight of dimethylaminoethyl methacrylate, 2 parts by weight of triacrylamine, 1.5 parts by weight of ammonium persulfate, 0.2 parts by weight of 2-hydroxy-2-sulfinic acid, 0.6 parts by weight of thioglycolic acid Parts by weight, 14 parts by weight of 32wt% sodium hydroxide aqueous solution, 1 part by weight of trisodium phosphate, and the rest is water, adjusted to 50% solid content.

[0034] (2) Acrylic acid and hydroxyethyl acrylate are dissolved in 15 parts by weight of deionized water to obtain the first solution; 2-hydroxy-2-sulfinic acid is dissolved in 30 parts by weight of deionized water to obtain the second solution; Thioglycoli...

Embodiment 2

[0039](1) Weigh each raw material component according to the following parts by weight: 180 parts by weight of methallyl polyoxyethylene polyether with a molecular weight of 5500, 12 parts by weight of methacrylic acid, 5 parts by weight of hydroxypropyl acrylate, unsaturated alcohol 6 parts by weight of urethane small monomer, 3 parts by weight of dimethylaminoethyl methacrylate, 5 parts by weight of tripropenylamine, 1.7 parts by weight of potassium persulfate, disodium salt of 2-hydroxy-2-sulfinic acid 0.4 parts by weight, 0.8 parts by weight of mercaptoethanol, 15 parts by weight of 32 wt% sodium hydroxide aqueous solution, 3 parts by weight of trisodium phosphate, and the rest is water, adjusted to 50% solid content.

[0040] (2) Dissolve methacrylic acid and hydroxypropyl acrylate in 15 parts by weight of deionized water to obtain the first solution; dissolve 2-hydroxy-2-sulfinic acid disodium salt in 30 parts by weight of deionized water to obtain The second solution; m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com