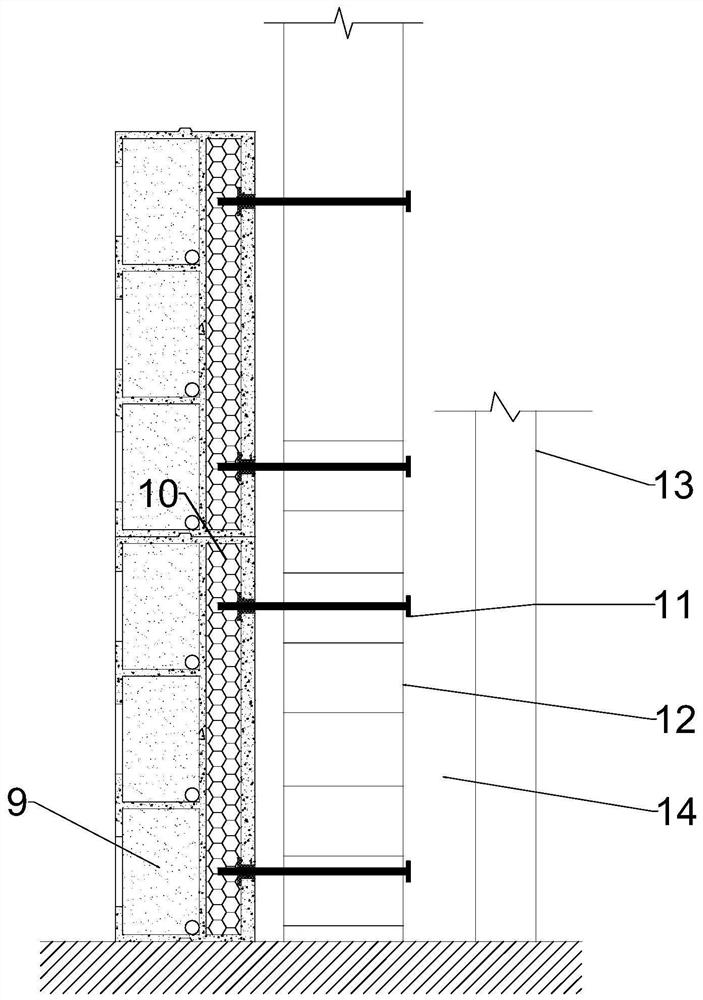

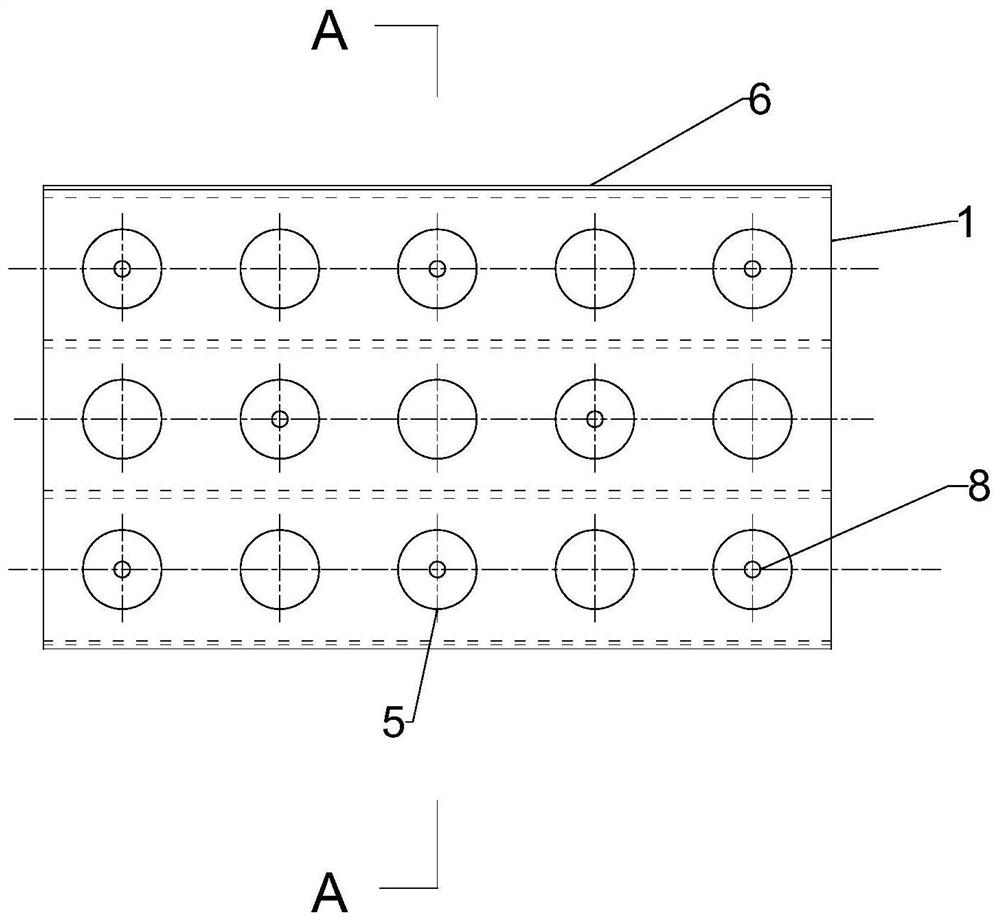

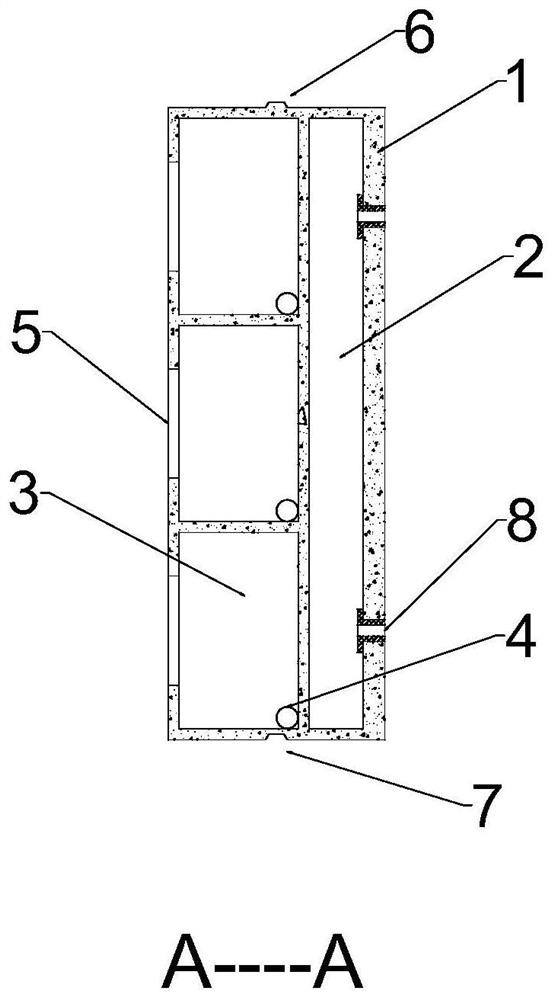

Non-dismantling formwork with planting and heat preservation functions and preparation method

A technology that does not need to dismantle templates and functions. It is applied in the field of green building materials. It can solve problems such as poor waterproof effect, complicated installation, and falling, and achieve good water resistance, high waste rate, and improved life expectancy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Prepare the non-demolition formwork with planting and heat preservation functions according to the following methods:

[0051] Step 1: Assemble the mold, and assemble the bottom mold, upper bottom mold, lower bottom mold, left mold, right mold, front side mold, rear side mold and core mold.

[0052] Step 2: Weigh each component of the fiber reinforced cementitious material slurry material: 500 parts of iron tailings powder, 320 parts of gypsum, 200 parts of mineral powder, 30 parts of calcium hydroxide, 10 parts of steel slag powder, 430 parts of fly ash, 30 parts of polyvinyl alcohol fiber, 10 parts of polycarboxylate superplasticizer, and 300 parts of water are fully stirred evenly to obtain a fiber-reinforced gelling material slurry.

[0053] Step 3: Squeeze the fiber-reinforced cementitious material slurry obtained in step 2, and cast it into the mold in step 1. After the fiber-reinforced cementitious material is hardened, pull out the core mold, remove the side mol...

Embodiment 2

[0059] Prepare the non-demolition formwork with planting and heat preservation functions according to the following methods:

[0060] Step 1: Assemble the mold, and assemble the bottom mold, upper bottom mold, lower bottom mold, left mold, right mold, front side mold, rear side mold and core mold.

[0061] Step 2: Weigh each component of the fiber reinforced cementitious material slurry material: 500 parts of iron tailings powder, 35 parts of gypsum, 300 parts of mineral powder, 3 parts of calcium hydroxide, 10 parts of steel slag powder, 430 parts of fly ash, 22 parts of polyvinyl alcohol fiber, 5 parts of polycarboxylate superplasticizer, and 400 parts of water are fully stirred evenly to obtain a fiber-reinforced gelling material slurry. Wherein the polyvinyl alcohol fiber length is 6mm.

[0062] Step 3: Squeeze the fiber-reinforced cementitious material slurry obtained in step 2, and cast it into the mold in step 1. After the fiber-reinforced cementitious material is hard...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com