Light gypsum board capable of preventing neutron radiation and preparation method thereof

A technology for preventing neutron radiation and gypsum board, which is applied in the field of building materials, can solve the problems such as light gypsum boards that have not yet been seen, and achieve the effects of strong functionality, high waste rate and good stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

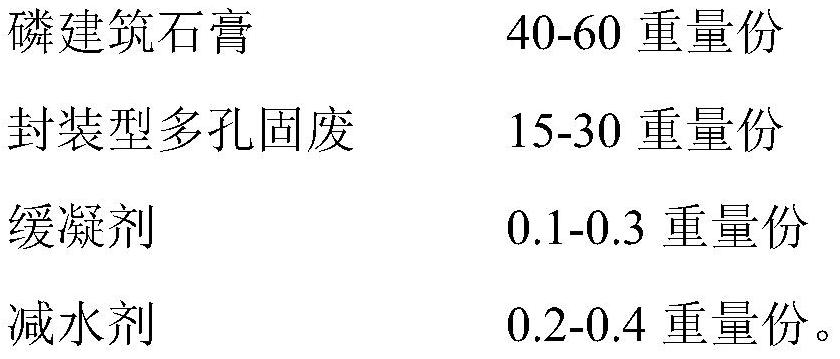

[0030] A neutron radiation-resistant lightweight gypsum board and a preparation method thereof, the raw material components and parts by mass are as follows:

[0031]

[0032] The phospho-building gypsum is obtained by calcining phosphogypsum at 107° C. for 2 hours, with a 2-hour flexural strength of 2.3 MPa and a 2-hour compressive strength of 4.7 MPa.

[0033] The encapsulated porous solid waste is a waste aerated building block, in which two kinds of particles with a particle size of 1-3mm and 3-5mm are mixed in a weight ratio of 1:2.

[0034] The encapsulated porous solid waste absorbs 0.2% boric acid solution under vacuum conditions, and then encapsulates it with 0.5% boron-containing polymethyl methacrylate.

[0035] The boron element in the polymethyl methacrylate exists in the form of boron-containing nanoparticles, such as boron slag, boron mud, boronite, or commercially available chemically synthesized particles with a particle size of 0.5-1 μm after wet grinding....

Embodiment 2

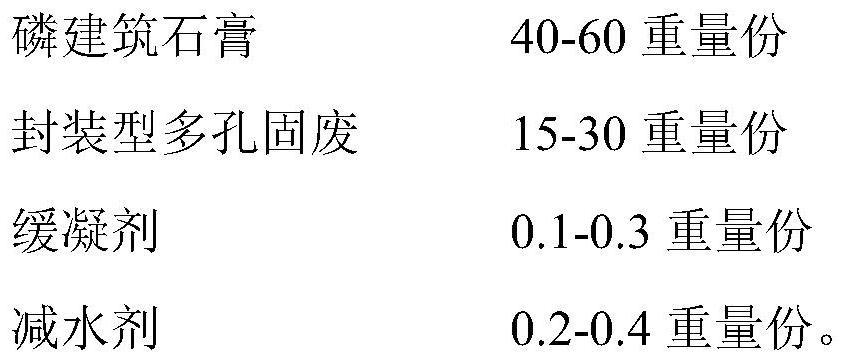

[0046] A neutron radiation-resistant lightweight gypsum board and a preparation method thereof, the raw material components and parts by mass are as follows:

[0047]

[0048] The phospho-building gypsum is obtained by calcining phosphogypsum at 150° C. for 2.5 hours, with a 2-hour flexural strength of 2.8 MPa and a 2-hour compressive strength of 5.1 MPa.

[0049] The encapsulated porous solid waste is waste aerated block and waste foam concrete, in which the particle size of 1-3 mm and 3-5 mm are mixed according to the weight ratio of 1:1.5.

[0050] The encapsulated porous solid waste absorbs 0.4% boric acid solution under vacuum conditions, and then encapsulates it with polymethyl methacrylate containing 0.7% boron.

[0051] The boron element in the polymethyl methacrylate exists in the form of boron-containing nanoparticles, such as boron slag, boron mud, boronite, or commercially available chemically synthesized particles with a particle size of 0.5-1 μm after wet grin...

Embodiment 3

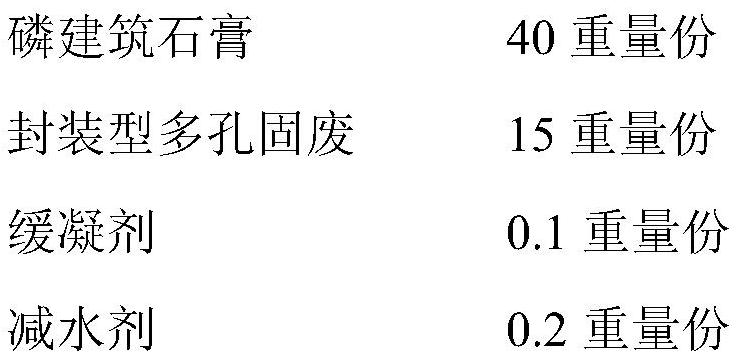

[0062] A neutron radiation-resistant lightweight gypsum board and a preparation method thereof, the raw material components and parts by mass are as follows:

[0063]

[0064] The phospho-building gypsum is obtained by calcining phosphogypsum at 170° C. for 3 hours, with a 2-hour flexural strength of 3.5 MPa and a 2-hour compressive strength of 5.8 MPa.

[0065] The encapsulated porous solid waste is waste brick and waste foam concrete, in which the particle size of 1-3 mm and 3-5 mm are mixed according to the weight ratio of 1:1.

[0066] The encapsulated porous solid waste absorbs 0.7% boric acid solution under vacuum conditions, and then encapsulates it with boron-containing 1% polymethyl methacrylate.

[0067] The boron element in the polymethyl methacrylate exists in the form of boron-containing nanoparticles, such as boron slag, boron mud, boronite, or commercially available chemically synthesized particles with a particle size of 0.5-1 μm after wet grinding. Nano-bo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexural strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com