Cordierite-spinel multiphase material and synthesis process thereof

A spinel and cordierite technology, which is applied in the field of cordierite-spinel composite phase materials and its synthesis process, can solve problems such as the limitation of regeneration application, and achieve the effects of low production cost, high conversion rate and high waste rate.

Inactive Publication Date: 2017-07-21

福建省建筑科学研究院有限责任公司

View PDF3 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] Coal gangue, sludge from aluminum profile factories, and water-quenched slag from stainless steel electric furnaces are all wastes produced in industrial production. The accumulation of these wastes is more than 100 million tons, such as coal gangue. About 100 million tons. Others, such as stainless steel electric furnace water quenching slag, are waste slag produced in the production of stainless steel raw materials. Because they contain heavy metals, their regeneration applications are greatly restricted.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

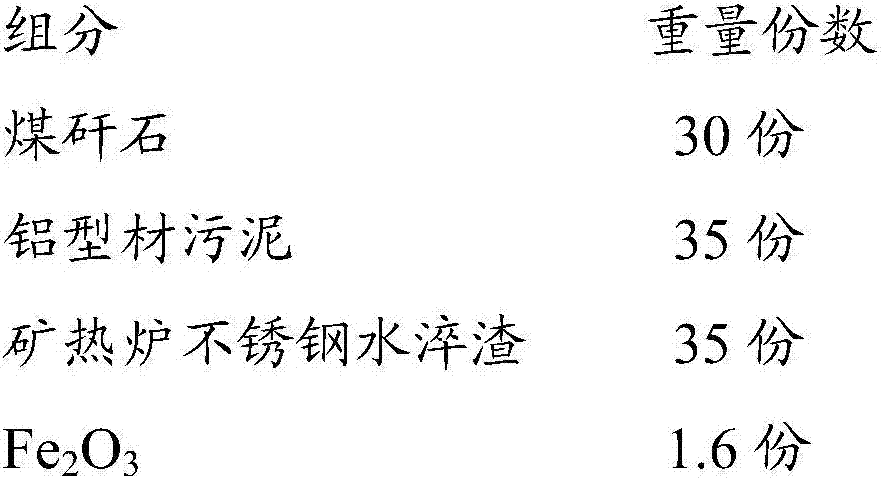

Embodiment 1

[0019]

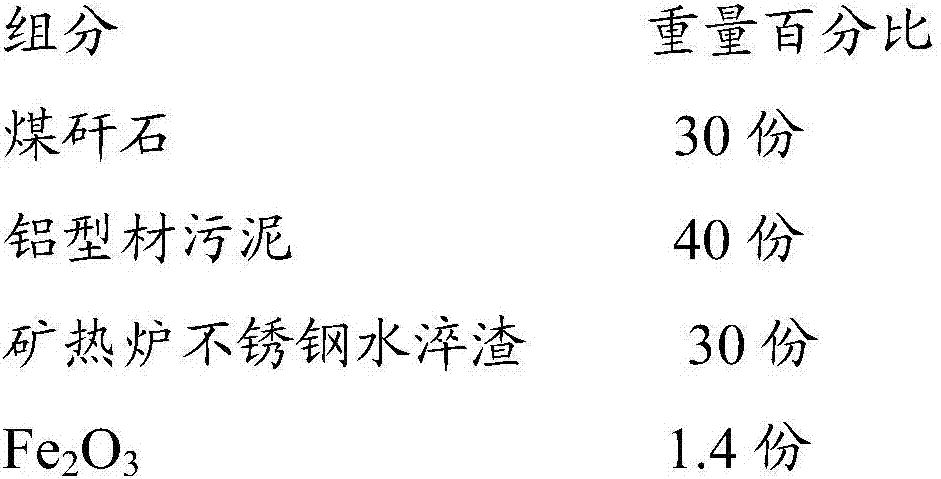

Embodiment 2

[0021]

Embodiment 3

[0023]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

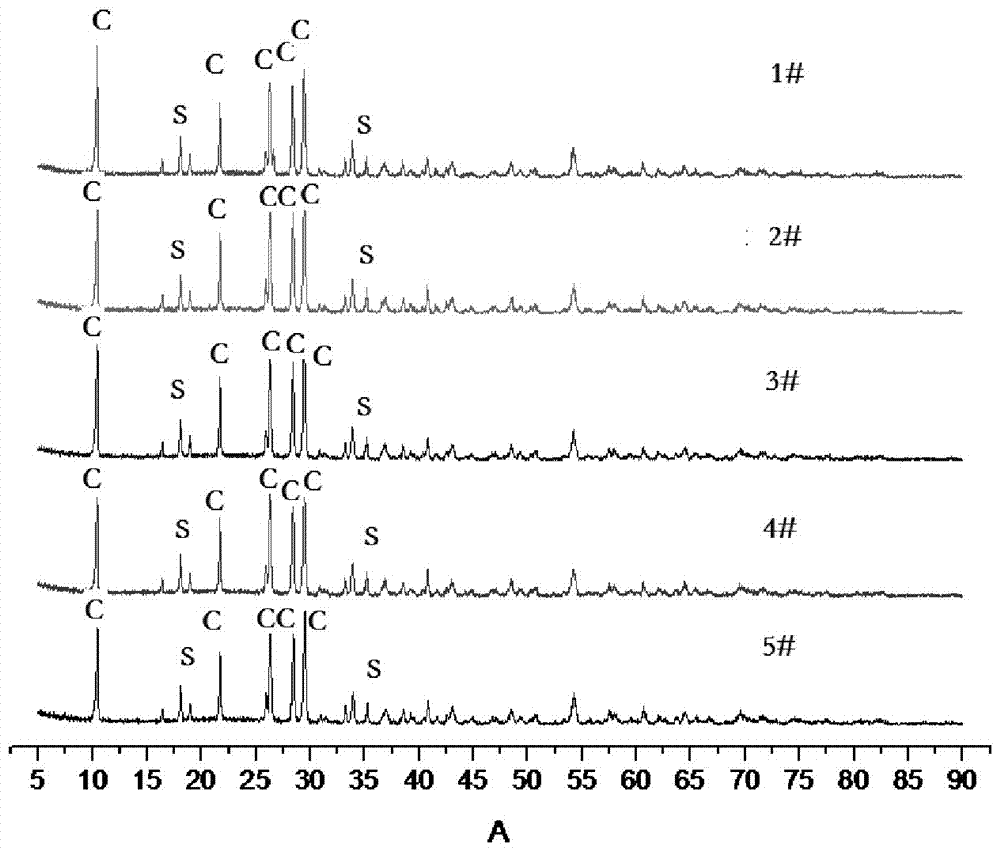

The invention provides a cordierite-spinel multiphase material and a synthesis process thereof. The cordierite-spinel multiphase material is prepared from, by weight, 30-40 parts of coal gangue, 35-45 parts of aluminum profile factory sludge, 15-35 parts of stainless steel electric furnace water quenching slag and 0.8-1.8 parts of Fe2O3 powder. The synthesis process includes the steps that the coal gangue, the aluminum profile factory sludge and the stainless steel electric furnace water quenching slag are respectively subjected to drying, powder grinding, screening, mixing, continuous pulverizing, the Fe2O3 powder is added, and stirring is performed to obtain dry powder; 15-20 g of water is added to per 100 g of dry powder, distilled water is added, stirring and pressure molding is performed, firing is performed in air atmosphere at the temperature of 1300-1350 DEG C for 3-5 hours, and natural cooling is performed. The cordierite-spinel multiphase material has the advantage of being high in purity, high waste utilization rate, low in production cost and high in conversion rate.

Description

technical field [0001] The invention specifically relates to a cordierite-spinel composite phase material and a synthesis process thereof. Background technique [0002] Coal gangue, aluminum profile factory sludge and stainless steel electric furnace water-quenched slag are all wastes produced in industrial production. The accumulation of these wastes is more than 100 million tons. About 100 million tons. Others, such as stainless steel electric furnace water quenching slag, are waste slag produced in the production of stainless steel raw materials. Because they contain heavy metals, their regeneration applications are greatly restricted. Therefore, how to effectively and comprehensively utilize these wastes has become a top priority. Cordierite has an extremely low thermal expansion coefficient and excellent thermal shock resistance, and is often used in occasions that require very strict thermal shock conditions, such as high-quality refractory materials, foam ceramics, h...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C04B35/443C04B35/195C04B35/622

CPCC04B35/443C04B35/195C04B35/62204C04B2235/3206C04B2235/3217C04B2235/3272C04B2235/3418C04B2235/5436C04B2235/602C04B2235/656C04B2235/6567C04B2235/658

Inventor 陈锋张蔚周敏林生凤黄芳

Owner 福建省建筑科学研究院有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com