Production line and process for recycling waste granite powder

A technology of waste rock powder and granite, which is applied in the direction of solid separation, sieve, grid, etc., can solve the problems of granite waste rock powder pollution, etc., and achieve the effects of avoiding secondary pollution, compact placement and reducing production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

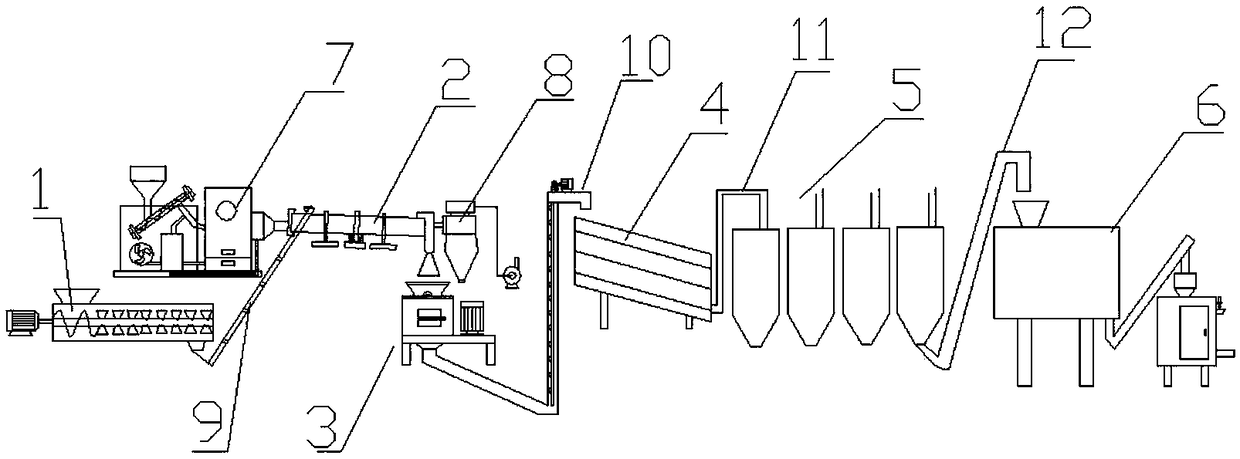

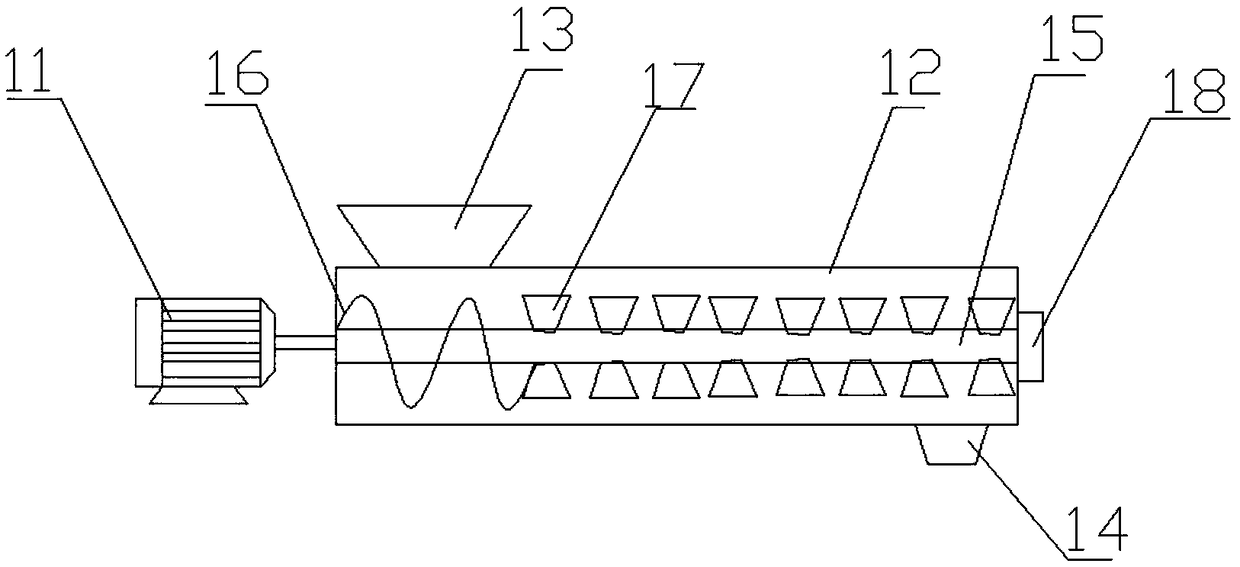

[0036] Such as figure 1 As shown, this embodiment relates to a granite waste rock powder recycling production line, including a double-shaft disintegrator 1, a 22-meter-long straight dryer 2, a composite crusher 3, a vibrating screen 4, a storage bin 5 and a stirring package machine 6, the discharge port of the double-shaft crusher 1 is connected to the feed port of the straight cylinder dryer 2 through the conveyor belt 9, and the composite crusher 3 is arranged below the discharge port of the straight cylinder dryer 2 The discharge port of the compound crusher 3 is connected with the vibrating screen 4 through the elevator 10; the vibrating screen 4 is connected with some storage bins 5 through the air pressure conveying device 11, and the storage bin 5 is connected with the stirring packaging machine 6 by the screw conveyor 12 connect.

[0037] The feed end of the straight tube dryer 2 is connected with a biomass particle combustion furnace 7, and the discharge end of the ...

Embodiment 2

[0045] This embodiment relates to a process for recycling granite waste rock powder, comprising the following steps:

[0046] (1) Disintegration: Granite waste rock powder is sent to the double-shaft disintegrator by a forklift, and the massive granite waste rock powder is initially broken up, and the disintegrated granite waste rock powder is granular.

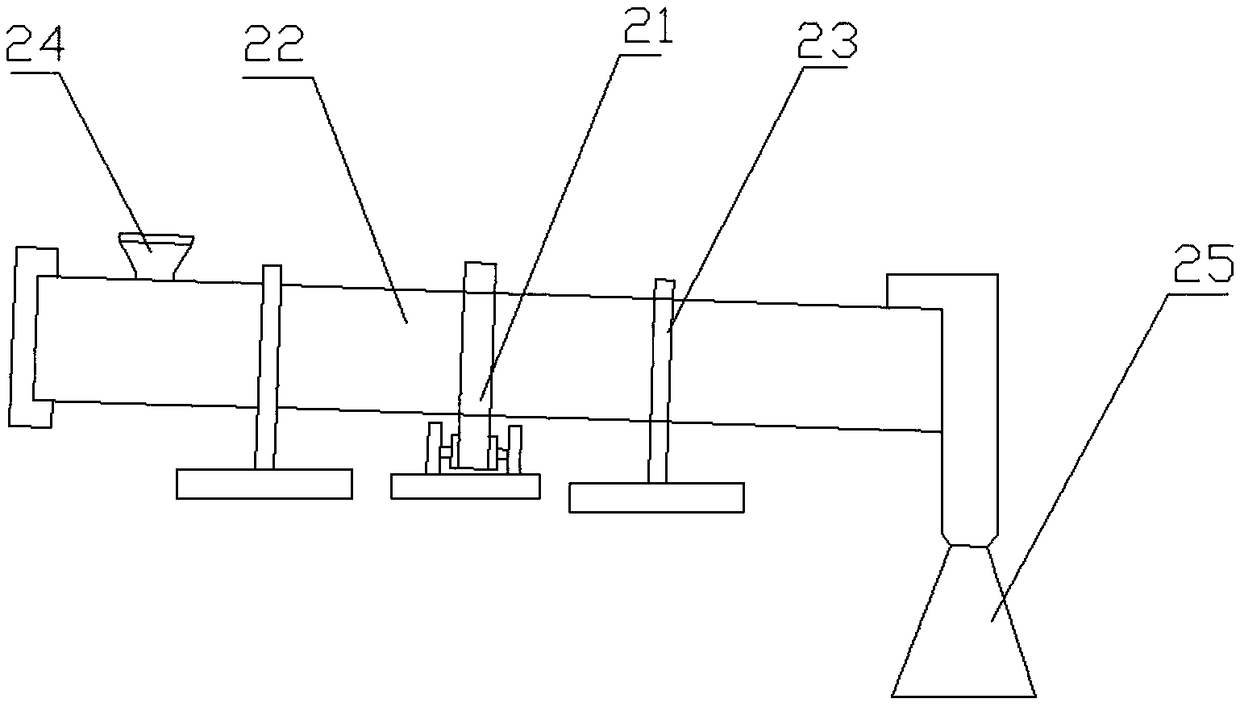

[0047] (2) Drying: After the granular granite waste rock powder is discharged from the discharge port of the double-shaft crusher, it enters the straight dryer through an inclined conveyor belt for drying; the heat source of the straight dryer passes through the biomass burning furnace. It is provided that the flame of the biomass combustion furnace is in direct contact with the granite waste rock powder, and before the granite waste rock powder is discharged from the straight cylinder dryer, the dust and combustion substances in the granite waste rock powder are removed by a negative pressure powder modification device.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com