A kind of polyvinyl alcohol-tannic acid-boric acid ternary cross-linked hydrogel, preparation method and application

A technology of cross-linked hydrogel and polyvinyl alcohol, which is applied in prosthesis, tissue regeneration, medical science, etc., can solve the problems of unfriendly environment, long time, poor self-healing performance, etc., and achieve simple process and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

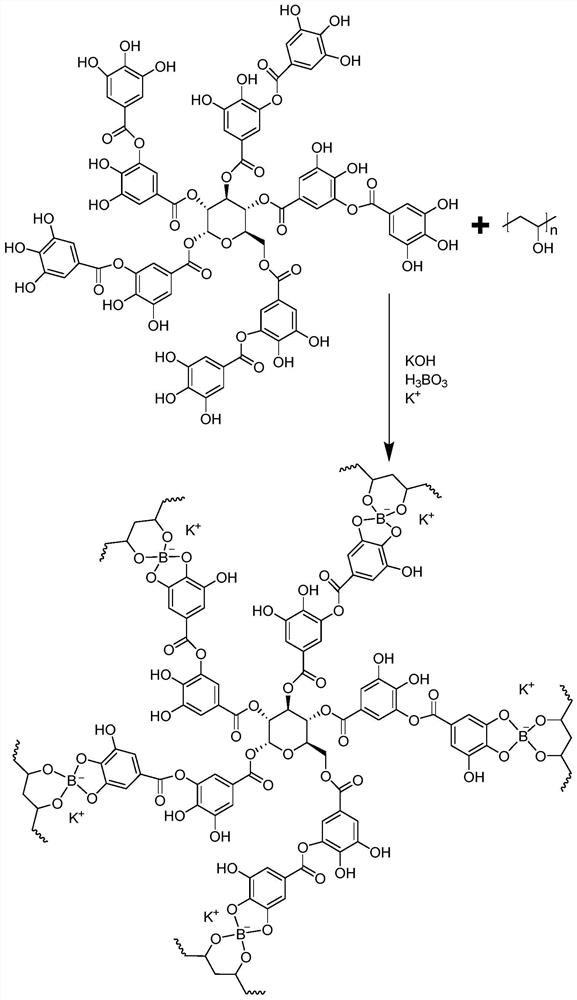

Method used

Image

Examples

Embodiment 1

[0029] Dissolve 0.1 g of tannic acid, 0.1 g of boric acid, and 0.2 g of potassium hydroxide in 8.5 g of deionized water, oscillate ultrasonically, and stir in an oil bath at 90° C. for 15 min to obtain a brown solution. Then slowly add 1.0g PVA and 0.1g potassium chloride in an oil bath at 90℃, and stir for 2h. A brown hydrogel was obtained after cooling.

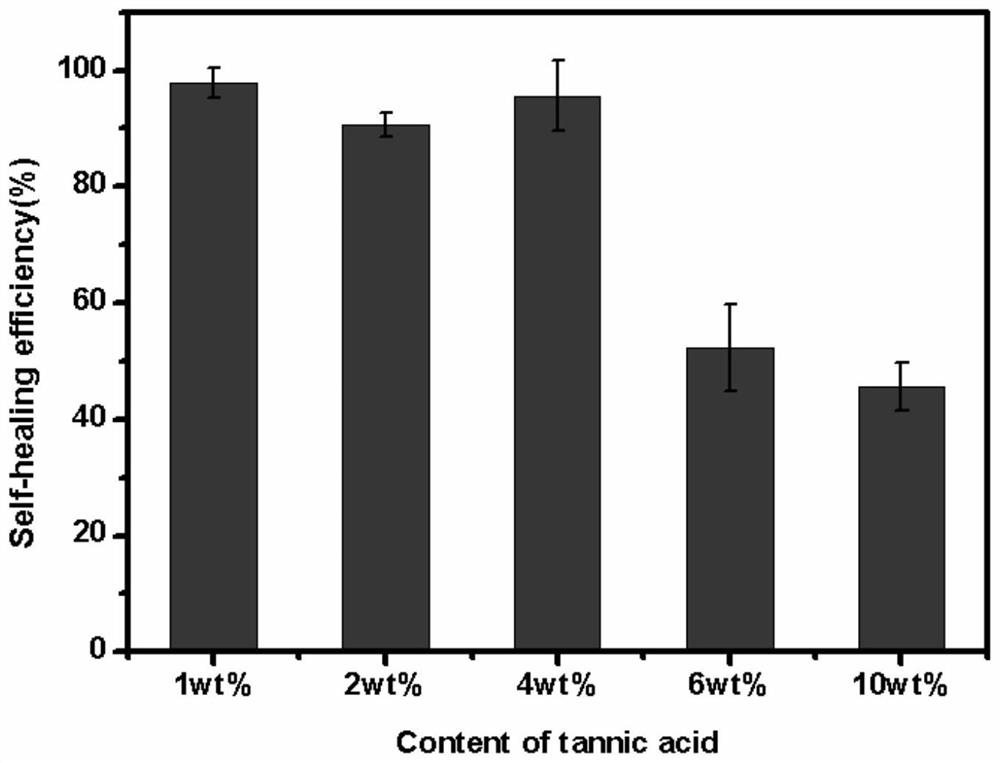

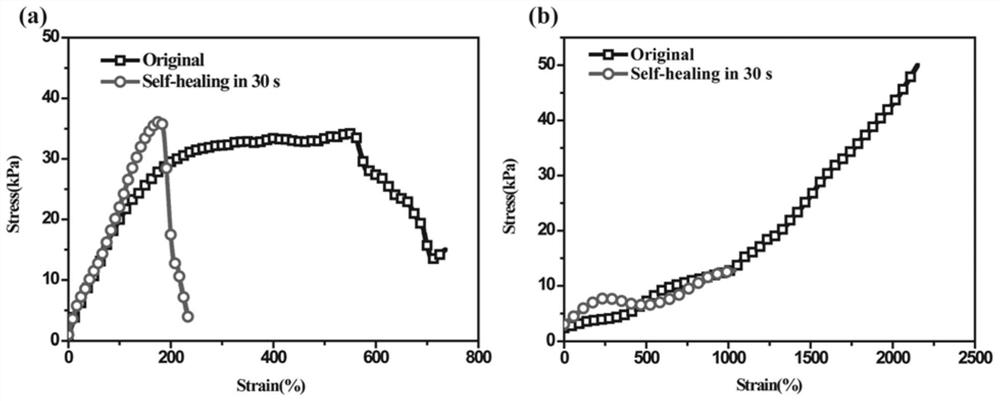

[0030] Such as Figure 4 , the ternary cross-linked hydrogel prepared in this example realizes effective self-repair within 30s; as Figure 5 , the original shape (a) of the ternary cross-linked hydrogel prepared in this example, after being fixed with a mold at room temperature for 30 minutes (b), the sample shape (c) returned to room temperature by heating in a water bath at 80°C. Such as Figure 6 , the ternary cross-linked hydrogel prepared in this example has dynamic covalent cross-linking and physical cross-linking structure, and there are reversible borate bonds and hydrogen bonds, and the hydrogen bonds include h...

Embodiment 2

[0032] Dissolve 0.2 g of tannic acid, 0.1 g of boric acid, and 0.2 g of potassium hydroxide in 8.4 g of deionized water, oscillate ultrasonically, and stir in an oil bath at 50° C. for 45 min to obtain a brownish-yellow solution. Then slowly add 1.0g PVA and 0.1g potassium chloride in an oil bath at 90℃, and stir for 5h. A brown hydrogel was obtained after cooling.

Embodiment 3

[0034] Dissolve 0.4g of tannic acid, 0.1g of boric acid, and 0.2g of potassium hydroxide in 8.2g of deionized water, oscillate ultrasonically, and stir in an oil bath at 60°C for 30min to obtain a brownish-yellow solution. Then slowly add 1.0g PVA and 0.1g potassium chloride in 90℃ oil bath, and stir for 3h. A tan hydrogel was obtained after cooling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com