Light permeable flexible rubber pavement brick and preparation method thereof

A pavement brick and rubber technology, used in ceramic products, climate sustainability, other household appliances, etc., can solve the problems of low compressive strength, low strength, poor foot feel, etc., achieve good noise reduction and sound absorption performance, and ensure water permeability. Good performance, flexibility and comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

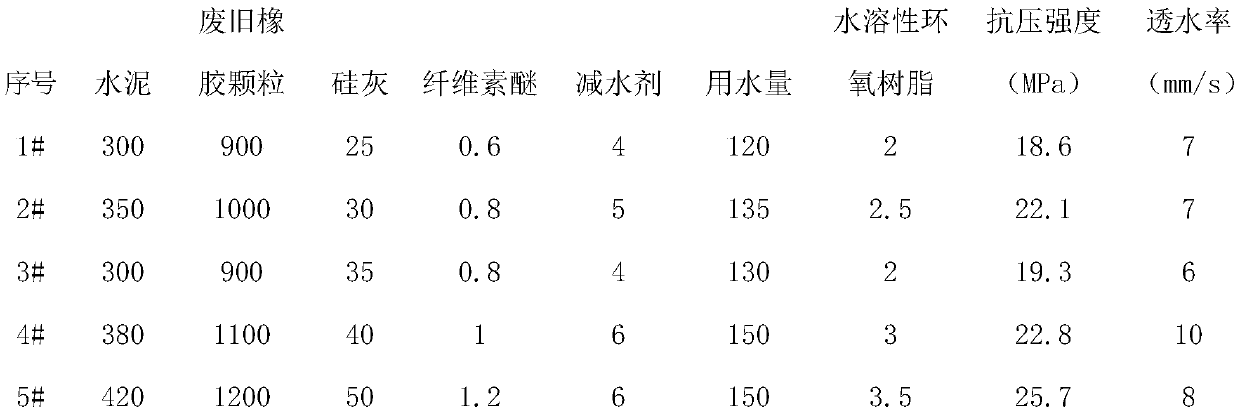

Examples

preparation example Construction

[0037] The present invention also relates to a method for preparing the above-mentioned lightweight water-permeable flexible rubber pavement brick. The steps of the preparation method are as follows:

[0038] Step 1) Mix all the cement, silica fume, and cellulose ether in proportions, stir evenly, then add all the waste rubber particles, and continue to stir with the powder to make them evenly mixed;

[0039] Step 2) Mix 80% of the water with all the water reducing agent and stir uniformly, and then add it to the solid mixture that is uniformly stirred in the above step 1). After the mixture is uniformly mixed, let it stand for a period of time;

[0040] Step 3) Pour all the water-soluble epoxy resin into the remaining 20% water, stir evenly, then add it to the mixture of step 2) above, and continue to stir and mix;

[0041] Step 4) Put the mixed material mixed in the above step 3) into the mold. The material should be loaded in layers, and the thickness of each layer should be contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com