Low grade fly ash mixed slurry used for concrete and preparation method thereof

A mixed slurry, low-grade technology, applied in the direction of solid waste removal, etc., can solve the problems of unsuitable concrete mass production, high cost of modifiers and instruments, complex production process, etc., to promote secondary hydration. The effect of simple reaction and modification production process and high waste rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

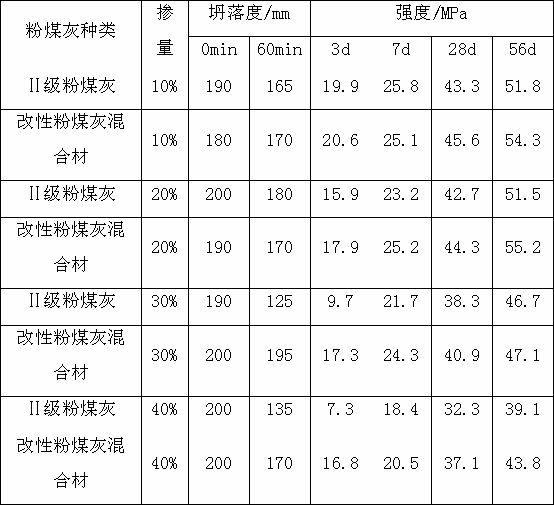

Embodiment 1

[0035] Step 1, raw material preparation: select low-grade fly ash, industrial waste residue, modifier and recycled water from the mixing station; according to the mass percentage of each component: low-grade fly ash solid content 52%, steel slag 10%, modified The agent is 2% gypsum, 1% triethanolamine and 35% recycled water from the mixing station. The recycled water from the mixing station contains the quality of water in low-grade fly ash.

[0036] The low-grade fly ash has a moisture content of 10%-25%, a sulfur trioxide content of ≤3%, a carbon content of ≤12%, and a sieve residue of 45 μm square hole ≤50%.

[0037] The industrial waste slag is steel slag or slag, with a sulfur trioxide content of ≤3%, a carbon content of ≤2%, and a sieve residue of 80 μm square hole sieves of ≤25%.

[0038] The mass percentages of the various components of the modifier are as follows: the reinforcement component accounts for 50%-80%, and the surface activation component accounts for 20%-5...

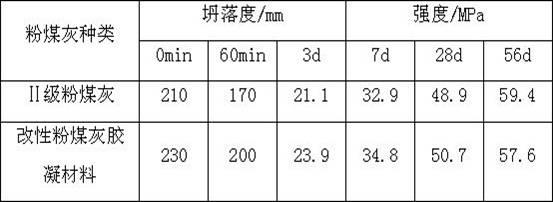

Embodiment 2

[0047]Step 1, raw material preparation: select low-grade fly ash, industrial waste residue, modifier and recycled water from the mixing station; the mass percentage of each component is: low-grade fly ash solid content 49%, slag 9%, modifier for Na 2 SO 4 2% and 1% of polycarboxylate polymer and 39% of the recycled water of the mixing station, the recycled water of the mixing station contains the quality of the water in the low-grade fly ash.

[0048] The low-grade fly ash has a moisture content of 10%-25%, a sulfur trioxide content of ≤3%, a carbon content of ≤12%, and a sieve residue of 45 μm square hole ≤50%.

[0049] The industrial waste slag is steel slag or slag, with a sulfur trioxide content of ≤3%, a carbon content of ≤2%, and a sieve residue of 80 μm square hole sieves of ≤25%.

[0050] The mass percentages of the various components of the modifier are as follows: the reinforcement component accounts for 50%-80%, and the surface activation component accounts for 20...

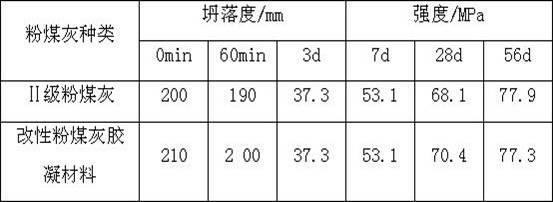

Embodiment 3

[0059] Step 1, raw material preparation: select low-grade fly ash, industrial waste residue, modifier and recycled water from the mixing station. The mass percentage of each component is: low-grade fly ash solid content 37%, slag 15%, Na 2 SiO 4 2% and 1% of triethanolamine, 45% of recycled water from the mixing station, and the recycled water from the mixing station contains the quality of low-grade fly ash reclaimed water.

[0060] The low-grade fly ash has a moisture content of 10%-25%, a sulfur trioxide content of ≤3%, a carbon content of ≤12%, and a sieve residue of 45 μm square hole ≤50%.

[0061] The industrial waste slag is steel slag or slag, with a sulfur trioxide content of ≤3%, a carbon content of ≤2%, and a sieve residue of 80 μm square hole sieves of ≤25%.

[0062] The mass percentages of the various components of the modifier are as follows: the reinforcement component accounts for 50%-80%, and the surface activation component accounts for 20%-50%.

[0063] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com