Red mud autoclaved brick and preparation method thereof

An autoclaved brick and red mud technology, applied in the field of building materials, can solve the problems of ineffective and large-scale utilization of red mud, low utilization rate of red mud, endangering human health, etc., so as to avoid product cracking, improve comprehensive utilization level, and benefit The effect of high waste rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

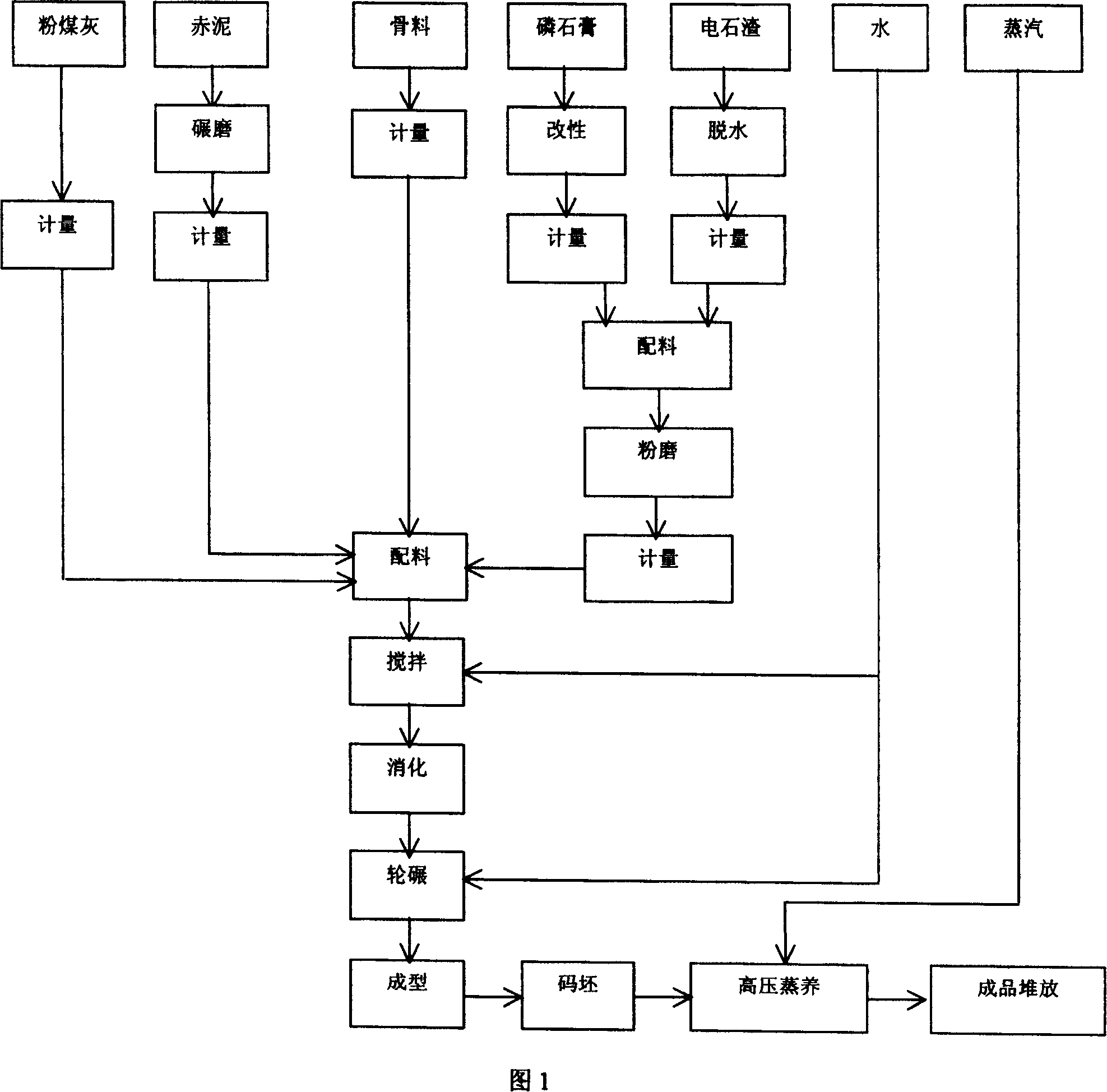

Method used

Image

Examples

Embodiment 1-4

[0020] An autoclaved red mud brick, which is prepared from red mud, fly ash, carbide slag, aggregate and modified phosphogypsum raw materials, the proportion of the autoclaved red mud brick is shown in Table 1.

[0021] Said red mud: water content 55%, magnesium oxide content < 2.5%. Aggregate: meet the requirements of GB / T14684-2001 "Sand for Construction". The modified phosphogypsum: the phosphogypsum conforming to GB / T5483-96 "Gypsum" is calcined at a temperature of 640-660°C. Among them, the red mud is ground for 10 minutes, and the modified phosphogypsum and carbide slag are ground for 15 minutes.

[0022] Table 1 Experimental ratio

[0023] serial number

red mud

aggregate

Carbide slag

Example 1

Example 2

Example 3

Example 4

25

30

35

40

10

15

10

10

55

45

37

35

8

8

14

10

2

...

Embodiment 5

[0031] An autoclaved red mud brick, which is prepared from red mud, fly ash, calcium carbide slag, aggregate and modified phosphogypsum raw materials, the weight percentage of each raw material is: red mud 25%, fly ash 30% , aggregate 35%, carbide slag 8%, modified phosphogypsum 2%.

[0032] Said red mud: water content 55%, magnesium oxide content < 2.5%. Aggregate: meet the requirements of GB / T14684-2001 "Sand for Construction". The modified phosphogypsum: the phosphogypsum conforming to GB / T5483-96 "Gypsum" is calcined at a temperature of 640-660°C. Among them, the red mud grinding time is 15 minutes, and the modified phosphogypsum and carbide slag grinding time is 20 minutes.

[0033] Its preparation method is with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com