Pyrite beneficiation tailing autoclaved aerated concrete block and production process thereof

A concrete block, autoclaved gas filling technology, applied in the direction of climate sustainability, other household appliances, sustainable waste treatment, etc., can solve the problems of utilization of pyrite beneficiation tailings, production technology and methods, etc., to achieve Good processing performance, good shock resistance and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The pyrite ore dressing tailings autoclaved aerated concrete block provided in this embodiment is made of the following raw materials in parts by weight:

[0029] Pyrite ore dressing tailings 50

[0030] River sand 25

[0031] lime 19

[0032] cement 5

[0033] plaster 1

[0034] Aluminum powder paste 0.09

[0035] Foam stabilizer 0.07

[0036] The production process of the pyrite dressing tailings autoclaved aerated concrete block provided in this embodiment comprises the following steps:

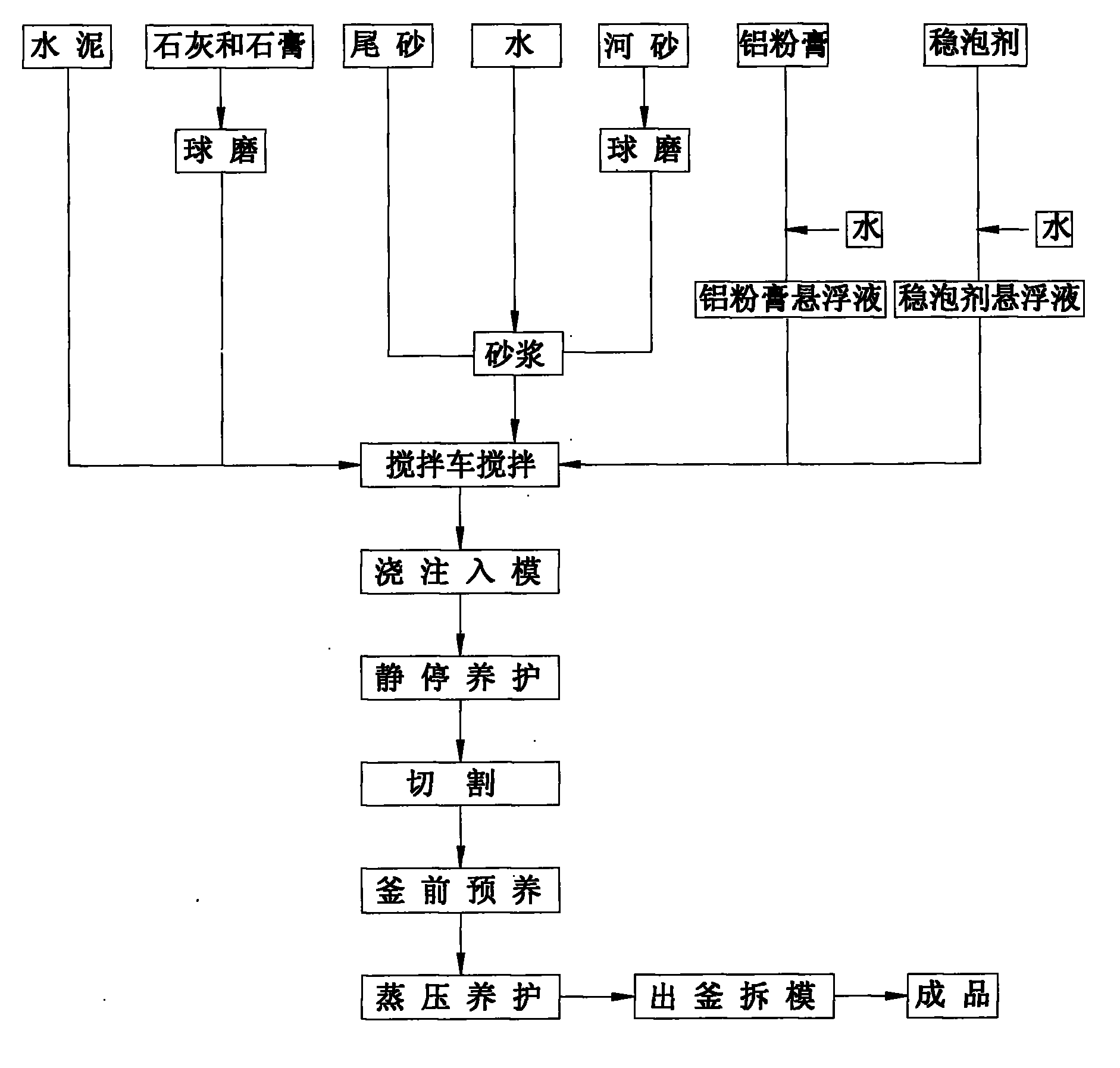

[0037] (1) Preparation of raw materials: Mix river sand with pyrite beneficiation tailings according to the above ratio, add water and stir in a pulping tank to make a specific gravity of 1.70g / cm 3 The mortar is stored in the mortar tank for later use; the crushed lime and gypsum are mixed according to the above ratio, and after being mixed by a lime ball mill, they are stored in the lime tank for later use; the aluminum powder paste and the foam stabilizer are added with wat...

Embodiment 2

[0047] The pyrite ore dressing tailings autoclaved aerated concrete block provided in this embodiment is made of the following raw materials in parts by weight:

[0048] Pyrite ore beneficiation tailings 75

[0049] lime 15

[0050] cement 9

[0051] plaster 1

[0052] Aluminum powder paste 0.09

[0053] Foam stabilizer 0.06

[0054]Among them, lime and gypsum need to be ball milled before use, and the specific surface area of lime and gypsum after ball milling is 3500-4000cm 2 / g, pyrite beneficiation tailings do not need ball milling process.

[0055] The production process of the pyrite dressing tailings autoclaved aerated concrete block provided in this embodiment comprises the following steps:

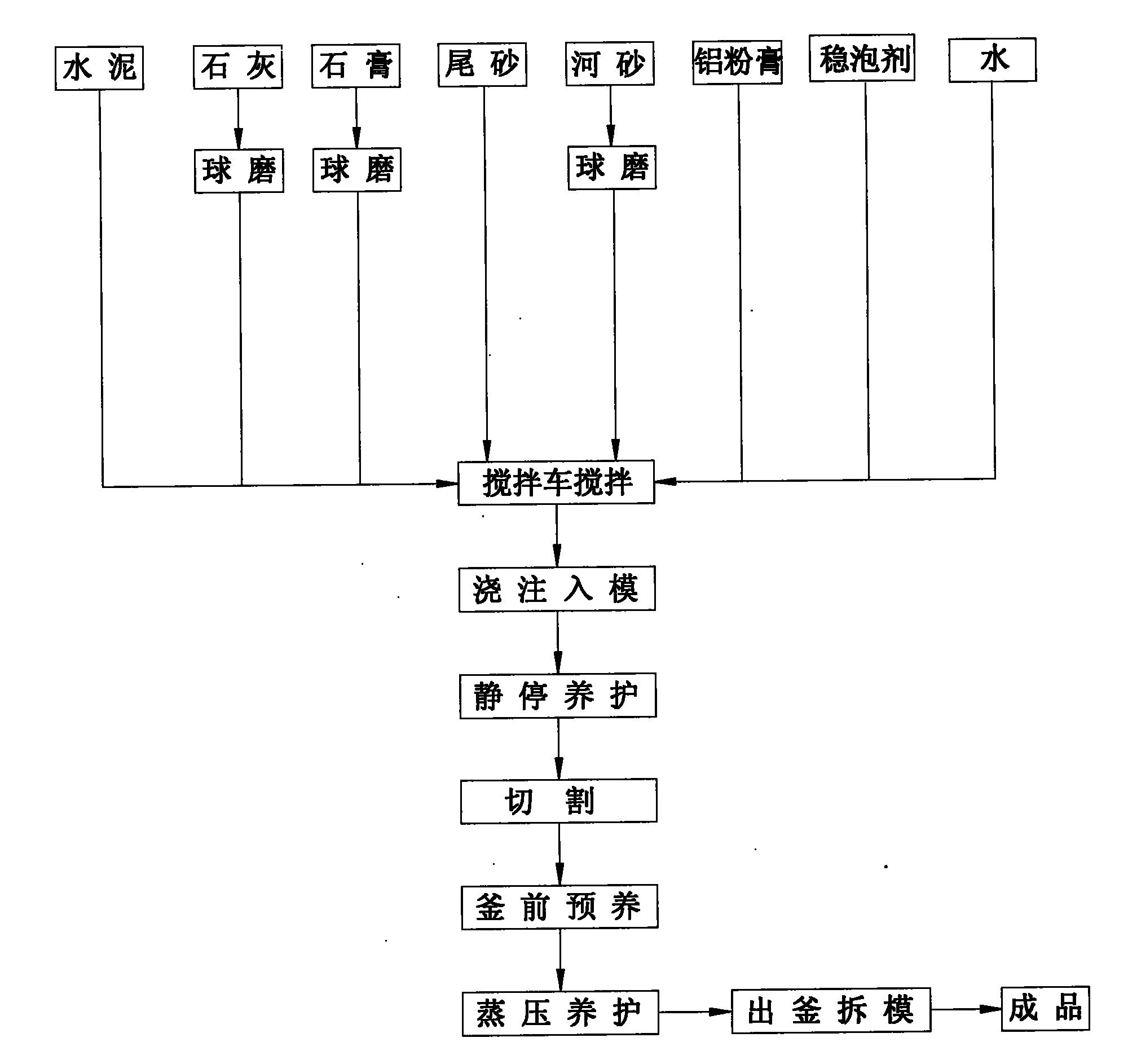

[0056] (1) Raw material preparation: Add water to pyrite dressing tailings and stir in a slurry tank to make a specific gravity of 1.72g / cm 3 The mortar is stored in the mortar tank for later use; the crushed lime and gypsum are mixed according to the above ratio, and aft...

Embodiment 3

[0066] The pyrite ore dressing tailings autoclaved aerated concrete block provided in this embodiment is made of the following raw materials in parts by weight:

[0067] Pyrite ore dressing tailings 15

[0068] Sea sand 60

[0069] lime 20

[0070] cement 4

[0071] plaster 1

[0072] Aluminum powder paste 0.10

[0073] Foam stabilizer 0.05

[0074] Among them, river sand, sea sand or sedimentary sand must be ball milled before use. After ball milling, the fineness of river sand, sea sand or sedimentary sand is 0.08mm square hole sieve and the residue is less than 20%. Lime and gypsum need to be ball milled before use. The specific surface area of lime and gypsum is 3500-4000cm 2 / g, pyrite beneficiation tailings do not need ball milling process.

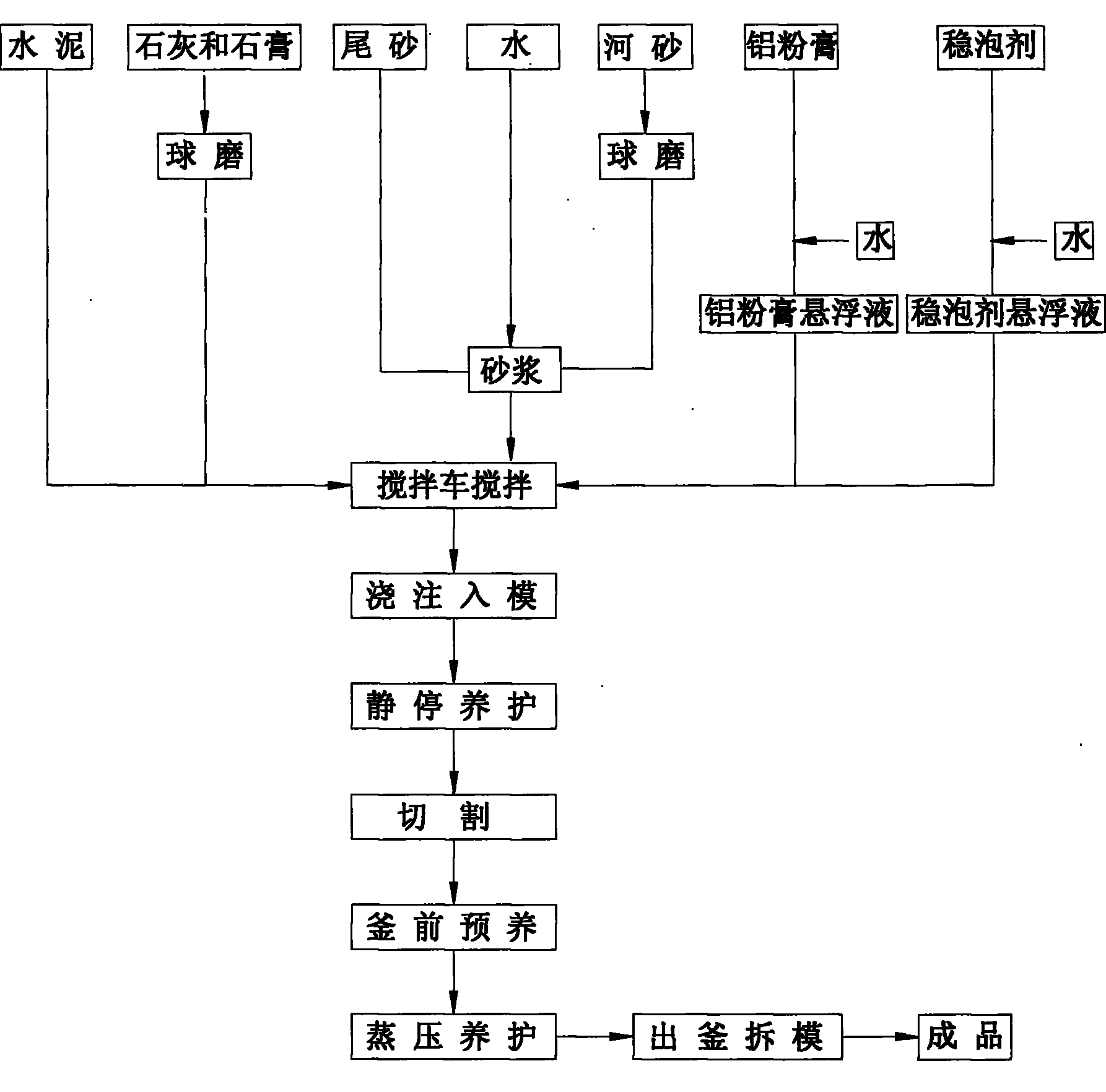

[0075] The production process of the pyrite dressing tailings autoclaved aerated concrete block provided in this embodiment comprises the following steps:

[0076] (1) According to the above formula, cast a mold (3.78m 3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com